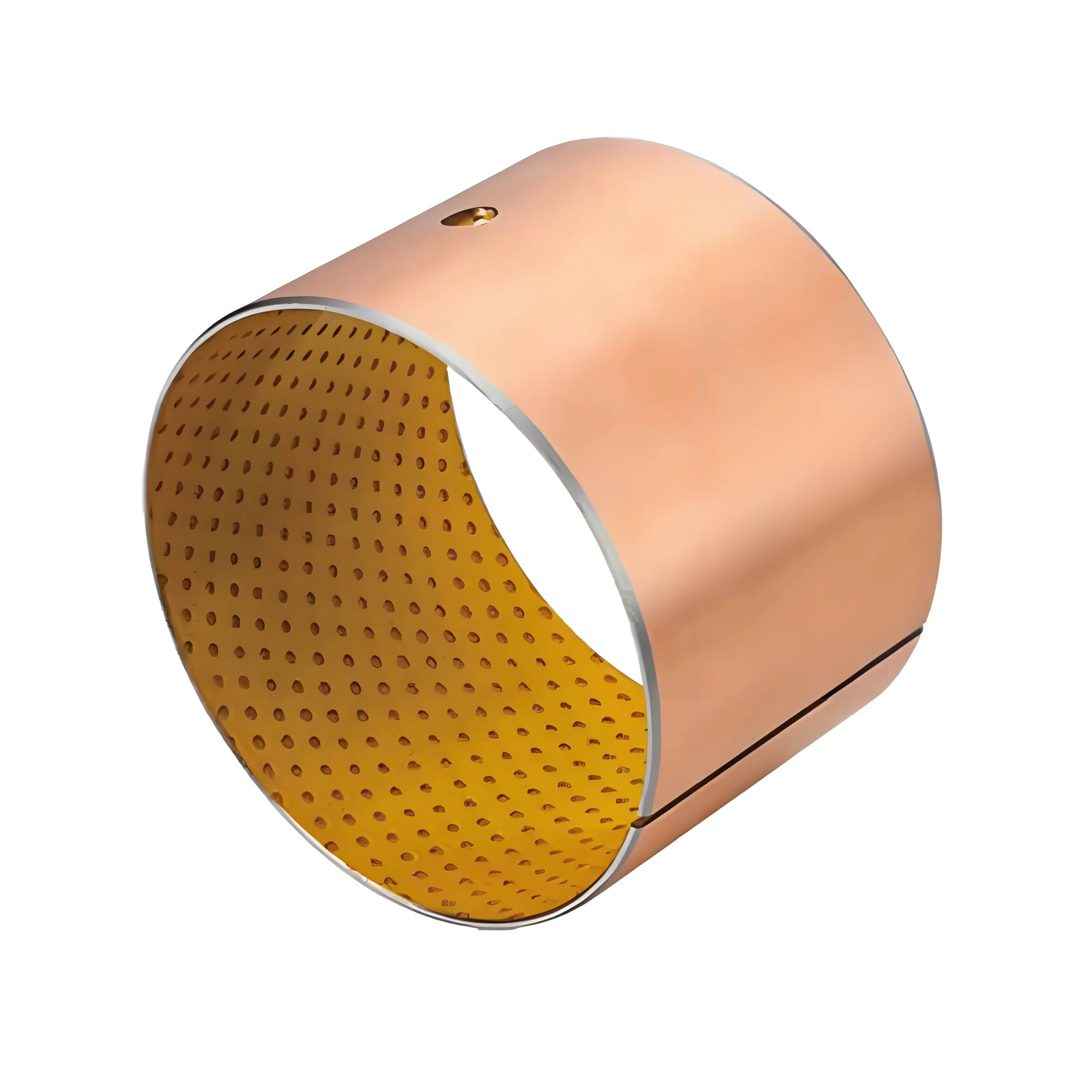

Metal-based boundary lubricated bearings

Description: With metal materials (such as copper alloys, steel) as the matrix, solid lubricants (graphite, PTFE, MoS₂, etc.) are embedded. When lubrication is insufficient, it can still effectively reduce friction through the boundary lubrication film, which is suitable for extreme working conditions.

Advantages:

✔ High load-bearing capacity – the metal matrix provides excellent mechanical strength

✔ Self-lubrication – solid lubricants reduce friction and maintenance

✔ Extreme resistance – adapt to -200℃~300℃ high temperature/vacuum/corrosive environment

✔ Long life – boundary lubrication film significantly reduces wear

✔ Environmental protection and energy saving – reduce lubricant consumption and reduce pollution

Introduction to Metal-based Boundary Lubricated Bearings

Metal-based boundary lubricated bearings are special bearings based on metal materials combined with solid lubricants. This product is suitable for use in environments with poor lubrication conditions, especially in high temperature, heavy load, high vacuum or corrosive environments. Its metal matrix provides strength support, while the solid lubricant reduces friction and wear, thereby extending the service life of the equipment.

Product Application and Features

Application Fields

Industrial Field

Used in metallurgical equipment, conveying systems, injection molding machines, etc.

Engineering Machinery

Commonly seen in excavation equipment, lifting machinery and tower cranes.

Energy Equipment

Suitable for wind turbines, water conservancy engineering equipment and boiler devices.

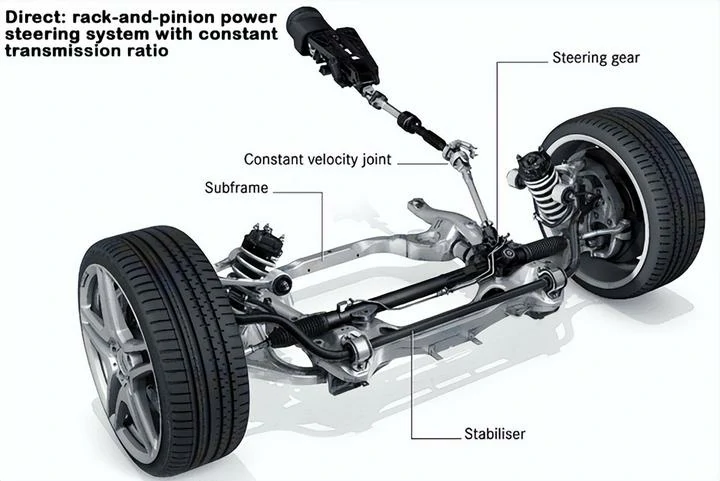

Transportation Equipment

Railway locomotives, port machinery and ship equipment.

Precision Industry

Applied to spacecraft, national defense facilities and high-end medical equipment.

Common brands:

SKF Metal-based Boundary Lubricated Bearings

NSK Metal-based Boundary Lubricated Bearings

NTN Metal-based Boundary Lubricated Bearings

KOYO Metal-based Boundary Lubricated Bearings

FAG Metal-based Boundary Lubricated Bearings

INA Metal-based Boundary Lubricated Bearings

NACHI Metal-based Boundary Lubricated Bearings

TIMKEN Metal-based Boundary Lubricated Bearings

Features

Strong wear resistance

The high-strength metal matrix ensures wear resistance and can adapt to heavy-load conditions.

Excellent lubrication effect

Solid lubricating materials significantly reduce friction under boundary lubrication conditions.

Adapt to special environments

Can work stably in high temperature, high vacuum and strong corrosive environments.

Low maintenance cost

The self-lubricating characteristics reduce the frequency of lubricant use.

Multiple specifications to choose from

A variety of materials and design forms can be provided according to needs.

Product Benefits

Save money

Reduce lubricant consumption and maintenance costs.

Improve durability

Still able to operate for a long time under extreme working conditions.

Enhance equipment reliability

Even in the absence of lubrication, it can still work efficiently.

Excellent environmental performance

Reduce the impact of lubricant leakage on the environment.

High flexibility

Customized design according to the specific needs of customers.

FAQ

Q1: How is it different from traditional bearings?

A1: Traditional bearings require lubricants to maintain operation, while metal-based boundary lubricated bearings can still run smoothly under poor lubrication conditions.

Q2: Is it necessary to add lubricant frequently?

A2: Self-lubricating products generally do not need to be frequently replenished with lubricants, but in specific scenarios, they can be replenished in appropriate amounts to extend service life.

Q3: What is the applicable temperature range?

A3: Depending on the material selection, the applicable temperature can reach -200°C to 300°C, or even higher.

Q4: Will the solid lubricant fall off?

A4: Solid lubricants are usually optimized and firmly bonded to the metal matrix, and will not fall off during normal use.

Q5: Can it be used for low speed and heavy load?

A5: Yes, this bearing is designed for low speed and heavy load applications and performs particularly well.

Q6: How to ensure its service life?

A6: By selecting appropriate materials and lubrication design, combined with optimized manufacturing processes, the service life can be greatly improved.

Q7: Can it be customized as required?

A7: The size, material and lubrication method can be customized for different working conditions to meet customer needs.

Metal-based boundary lubricated bearings are widely used in industrial fields and special environments due to their excellent wear resistance, high temperature resistance and maintenance-free properties. They are an ideal choice for reliability and economy.