Mounted Deep Groove Ball Bearings

Advantages and Features

1. Structural Advantages

Integrated design: Bearing and seat are integrated to reduce installation complexity and time.

Diverse seat types: Provide vertical seat, flange seat and suspension seat and other options to meet different installation requirements.

Flexible seal configuration: Optional rubber seal (RS), metal dust cover (ZZ), or open design to adapt to various working environments.

2. Performance characteristics

Easy to install: Directly fix, no additional adjustment of alignment is required, to improve efficiency.

Strong anti-pollution ability: The sealing design effectively blocks dust, water vapor and other pollutants from entering, extending service life.

Simple maintenance: With relubrication function, it reduces downtime and maintenance costs.

Economical and efficient: Standardized component design, strong versatility, reducing procurement and replacement costs.

3. Strong applicability

Excellent performance in medium and low speed operation scenarios, suitable for light to medium load applications.

High reliability can be maintained in harsh environments, such as dusty, humid or corrosive environments.

Mounted Deep Groove Ball Bearing units Overview

MountedDeep Groove Ball Bearing units are a compact unit that integrates a deep groove ball bearing with a bearing housing. They are known for their ease of installation, excellent sealing capabilities, and low-maintenance requirements. These bearings find extensive use in industries such as agriculture, conveyors, food processing, and textiles.

1. Applications

(1) Agricultural Machinery

Common Equipment: Tractors, harvesters, irrigation systems

Role: Supports transmission shafts and pulleys while tolerating dusty and humid conditions.

(2) Conveying Equipment

Common Equipment: Belt conveyors, chain conveyors, roller conveyor systems

Role: Reduces friction and boosts efficiency under light to medium loads.

(3) Food and Beverage Processing

Common Equipment: Filling machines, packaging machines, mixers

Role: Ensures compliance with food-grade lubrication, offering corrosion resistance and easy cleaning.

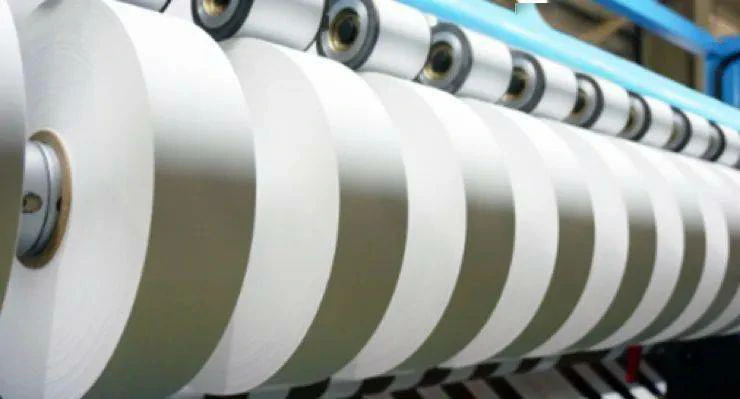

(4) Textile Machinery

Common Equipment: Spinning machines, looms, winding machines

Role: Operates at high speeds with minimal friction, reducing thread breakage.

(5) General Industrial Equipment

Common Equipment: Fans, pumps, small motors

Role: Provides an economical and reliable solution for light to medium loads.

2. Features and Advantages

(1) Structural Highlights

Preassembled Design: Combines the bearing and housing for faster setup.

Seal Options: Includes rubber seals (RS), metal shields (ZZ), and open designs.

Housing Types: Available in pillow block, flange block, and take-up units for diverse mounting needs.

(2) Performance Benefits

Advantage Description

Easy Installation Directly bolt-mounted, no alignment needed.

Simplified Maintenance Re-lubrication capability extends service life.

Strong Contamination Resistance Seals prevent entry of dust and moisture.

Cost-Effective Standardized designs enhance compatibility and reduce costs.

Common brands

SKF Mounted Deep Groove Ball Bearing units

FAG Mounted Deep Groove Ball Bearing units

NSK Mounted Deep Groove Ball Bearing units

KOYO Mounted Deep Groove Ball Bearing units

INA Mounted Deep Groove Ball Bearing units

NTN Mounted Deep Groove Ball Bearing units

TIMKEN Mounted Deep Groove Ball Bearing units

NACHI Mounted Deep Groove Ball Bearing units

3. Summary

Mounted Deep Groove Ball Bearing units are an economical and efficient solution for medium- to low-speed operations with light to moderate loads. Their modular construction simplifies installation, while optimized sealing and lubrication systems enhance reliability in challenging environments.

4. Frequently Asked Questions (FAQs)

Q1: How do mounted bearings differ from regular deep groove ball bearings?

Mounted bearings integrate the bearing and housing, making them easier to install, while standalone bearings require separate housings and are used in higher-precision setups.

Q2: Which sealing option should I choose?

Rubber Seals (RS): Best for dusty and damp conditions.

Metal Shields (ZZ): Protect against debris but are not waterproof.

Open Type: Requires external lubrication, suitable for clean environments.

Q3: Can mounted bearings handle axial loads?

Mounted deep groove ball bearings can support some axial load, but they are primarily designed for radial forces. For higher axial load capacity, consider mounted spherical roller bearings.

Q4: What are signs of bearing wear?

Unusual noise (e.g., grinding sounds)

Increased vibration

Excessive heat generation (>70°C requires attention)

Dried or leaking grease

Q5: What are key installation tips?

Avoid hammering the bearing directly; use appropriate tools.

Ensure alignment to prevent uneven loading.

Regularly lubricate with suitable grease.

Final Thoughts

Mounted Deep Groove Ball Bearing units serve as foundational components in industrial drive systems. Their user-friendly design, durability, and cost efficiency make them a preferred choice across various industries. Proper selection and maintenance can significantly enhance operational efficiency while minimizing downtime.