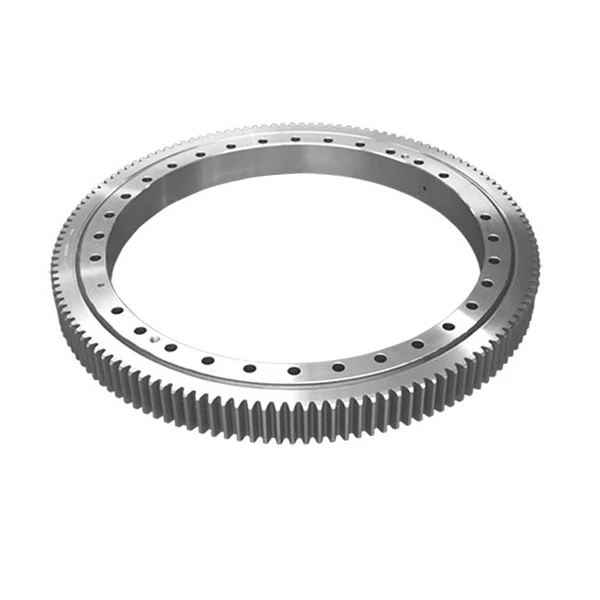

Double Row Unequal Diameter Ball Bearings

Double-row unequal diameter ball bearings are compact bearings designed to handle both radial and axial loads in both directions. Featuring two rows of balls with different diameters, they optimize load distribution and are ideal for applications requiring high load capacity in limited space.

Advantages and Features

Space-Saving Design: Compact structure suitable for installations with space constraints.

High Load Capacity: The double-row configuration significantly enhances load-bearing capability.

Enhanced Stability: Unequal diameter balls ensure even load distribution, improving stability and extending service life.

Material Versatility: Available in steel, stainless steel, or ceramic to meet various operational requirements.

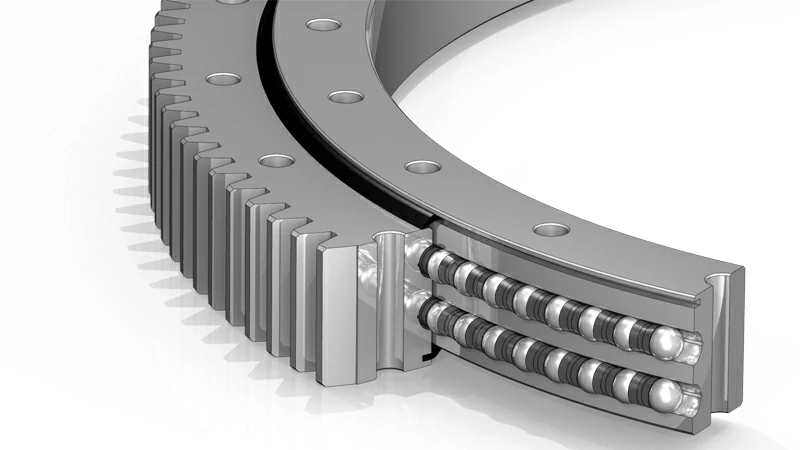

Low Maintenance: Sealed designs reduce the need for frequent lubrication and maintenance.

These bearings are widely used in automotive, industrial equipment, and aerospace sectors, valued for their reliability and efficiency.

See more at Slewing Ring Bearings Catalog.

Introduction to Double Row Unequal Diameter Ball Bearings

Double-row unequal diameter ball bearings are specialized components designed to accommodate both axial and radial loads simultaneously. With a compact and efficient design, they are ideal for applications where space is limited, and high load capacity is required.

Product Classification and Applications

Product Types:

Angular Contact: Suitable for conditions requiring significant axial and radial load handling.

Sealed Type: Provides excellent protection, ideal for dusty or harsh environments.

Open Type: Without seals, best for high-speed or clean operational conditions.

Custom Variants: Tailored designs for specific applications or requirements.

Key Applications:

Automotive Industry: Utilized in steering systems, gearboxes, and wheel bearings.

Industrial Machinery: Widely used in power transmission systems, motors, and conveyor systems.

Aerospace: Critical for flight components and landing gear assemblies.

Medical Devices: Ideal for high-precision, compact equipment.

Agricultural Machinery: Commonly used in harvesters, tractors, and heavy-duty equipment.

Advantages and Key Features

Advantages:

Space-Saving Design: Optimized for compact layouts while delivering high performance.

Reliability: High load capacity, suitable for demanding operating conditions.

Versatility: Accommodates a wide range of speeds and loads.

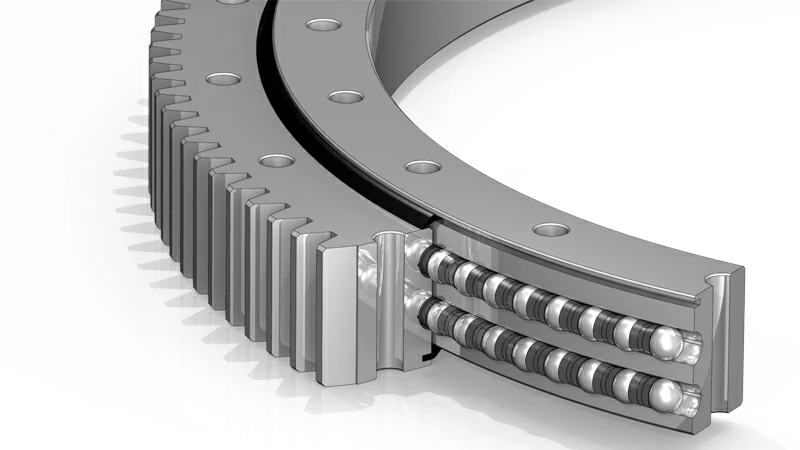

Optimized Load Distribution: Unequal diameter balls enhance load balance and performance.

Key Features:

Dual Row Structure: Increases load-carrying capacity.

Bidirectional Load Handling: Supports axial and radial loads simultaneously.

Material Options: Available in steel, stainless steel, and ceramic to suit diverse environments.

Low Maintenance: Sealed designs reduce the need for regular servicing.

Frequently Asked Questions (FAQ)

Q: Why use unequal diameter balls?

A: This design optimizes load distribution, enhancing efficiency and durability.

Q: Are these bearings suitable for high-speed applications?

A: Yes, particularly open-type bearings are designed for high-speed operation.

Q: What options are available for corrosion resistance?

A: Stainless steel and ceramic variants offer excellent corrosion resistance.

Q: What should I consider when selecting a bearing?

A: Evaluate load capacity, speed, environmental conditions, and dimensions, or consult a specialist for guidance.

Q: Do sealed bearings require maintenance?

A: Under normal operating conditions, sealed bearings are virtually maintenance-free.

Summary

Double-row unequal diameter ball bearings combine a compact design with exceptional performance, making them ideal for challenging load scenarios. Widely used across industries like automotive, industrial machinery, and aerospace, these bearings deliver reliable operation with high load capacity and minimal maintenance requirements. Their adaptability and customization options make them an indispensable solution for engineers seeking efficiency and durability in demanding applications.