Crossed cylindrical roller bearings

Introduction to Crossed Cylindrical Roller Bearings

Crossed cylindrical roller bearings are high-precision, high-rigidity bearings with rollers arranged crosswise at 90°. They can withstand radial, axial and overturning moments at the same time and are ideal for compact equipment.

Advantages and Features

High load-bearing capacity: supports multi-directional loads and is suitable for complex force environments.

High-precision rotation: cross-arrangement reduces offset and improves rotation accuracy.

Compact structure: saves space and adapts to miniaturized design requirements.

Easy installation: a single bearing replaces a multi-bearing structure to simplify design and assembly.

Strong reliability: low friction, smooth operation and long life.

See more at Slewing Ring Bearings.

Crossed cylindrical roller bearing overview

Crossed cylindrical roller bearings are a special type of bearing designed for high precision and high rigidity. Its internal structure uses rollers arranged crosswise at 90°, and the rollers are separated by isolation blocks to reduce friction, ensure smooth operation of the bearing and extend its service life.

Core features

Strong rigidity and high load-bearing capacity: The unique cross roller design enables it to withstand radial, axial and overturning moments.

Small footprint: Compact design, suitable for equipment that needs to save space.

High-precision rotation: The reasonable layout of the rollers improves the rotation accuracy of the bearing.

Easy to install: It can replace multiple traditional bearings and simplify the mechanical structure.

Product application areas

This type of bearing is commonly found in equipment with strict requirements on precision and rigidity, including but not limited to the following areas:

Industrial robots

Used in joints or rotating parts to meet their high precision and multi-directional force requirements.

Precision machining equipment

Applied in CNC machine tool turntables to ensure stable and efficient machining processes.

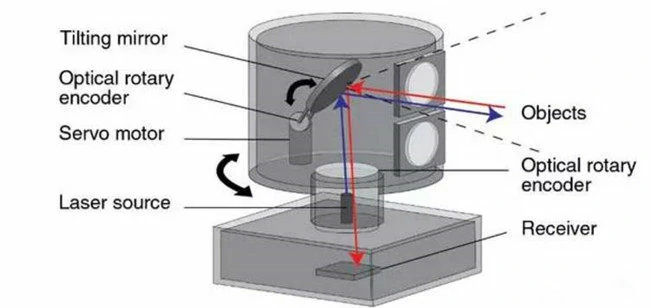

Optoelectronic systems

Used in rotating parts of radar or optical instruments to improve equipment performance.

Medical imaging equipment

In CT, MRI and other equipment, it provides precise support for rotating parts.

Aerospace and aviation

Applicable to high-reliability systems such as satellites and drones.

Characteristics and applicable analysis

Recommended application scenarios:

Precision control fields, such as robots and optical equipment.

Equipment with limited space but high rigidity requirements.

Mechanical systems that need to withstand multiple loads at the same time.

Non-ideal application scenarios:

Ultra-high-speed operation occasions: Its rolling resistance is large and it is not suitable for ultra-high-speed requirements.

Harsh environmental conditions: Such as high temperature or corrosive environment, whether it is applicable should be selected according to the actual material.

FAQ

1. What are the key points during installation?

Ensure that the installation base is flat and pollution-free, and operate strictly in accordance with the installation requirements.

2. How to judge the life of the bearing?

When the bearing rotation becomes unsmooth, noise occurs, or the gap is too large, it is necessary to consider replacement.

3. What are the common models on the market?

RB, RE, RU and other series are common choices, and the selection should be based on the specific equipment requirements.

4. How to choose the lubrication method?

Lubrication methods include oil lubrication and grease lubrication, which are determined according to the operating conditions of the equipment.

5. Is the price higher than that of ordinary bearings?

The unit price of cross cylindrical roller bearings is higher than that of ordinary bearings, but it can reduce the complexity of equipment maintenance and has better overall economic efficiency.

Conclusion

Cross cylindrical roller bearings play an important role in robots, precision machining equipment and other fields due to their high precision, compact structure and multi-load bearing capacity. Although the initial purchase cost is high, its reliability and performance can help the equipment achieve a longer service life and higher operating efficiency, making it the only choice for high-end equipment.