ニュース

Where Are Plain Bearings Used?: An Expert Guide to 7 Key Industrial Applications in 2026

Abstract Plain bearings, often referred to as bushings or journal bearings, represent a fundamental category of mechanical components designed to facilitate motion between surfaces through a sliding action. Unlike rolling-element bearings that utilize balls or rollers to minimize friction, plain bearings function based on the principles of tribology, where the interaction of surfaces in relative motion is managed through material selection, lubrication, and geometric design. This comprehensive exploration examines the diverse and demanding environments where plain bearings are utilized. The analysis covers their critical function in high-load, low-speed applications, and situations involving oscillatory or intermittent motion. Key industrial sectors, including automotive, heavy construction, aerospace, agriculture, and power generation, are investigated […]

A Practical Buyer’s Guide for 2026: What is a Plain Bearing & 5 Key Selection Criteria

Abstract A plain bearing is a mechanical element engineered to support a load and reduce friction between moving parts through a sliding action. Unlike rolling-element bearings that utilize balls or rollers, a plain bearing's functionality relies on direct surface contact, often separated by a thin film of lubricant. These components, also known as bushings or journal bearings, consist of a stationary outer surface and a rotating or sliding inner surface. Their design simplicity belies a sophisticated interplay of material science, tribology, and fluid dynamics. They are particularly adept at handling high static and dynamic loads, including shock and vibration, making them suitable for demanding industrial environments. The performance of a […]

Expert Guide 2026: What Are Plain Bearings Made Of? 7 Key Material Types

Abstract Plain bearings, fundamentally simple in concept yet complex in material science, are constructed from a diverse spectrum of materials tailored to specific operational environments. The selection of a material is not arbitrary; it is a deliberate engineering decision that dictates the bearing's performance characteristics, including its load-bearing capacity, frictional properties, thermal resistance, wear life, and chemical inertness. An inquiry into what are plain bearings made of reveals a landscape of metals, polymers, composites, and ceramics. Metallic options like bronze and babbitt offer high strength, while advanced polymers such as PTFE and PEEK provide self-lubricating properties for maintenance-free operation. Composite bearings synergize these benefits, combining metal backings with polymer linings. […]

What Are Plain Bearings?: An Expert Guide to Types, Materials & 7 Industrial Uses

Abstract This article provides a comprehensive examination of plain bearings, exploring their fundamental principles, design variations, and material compositions. It delineates the core concept of plain bearings as components that facilitate motion through a sliding action, contrasting them with the rolling mechanism of ball and roller bearings. The analysis extends to the diverse family of plain bearings, including sleeve, flange, and thrust types, clarifying common terminologies like "bushing." A significant portion is dedicated to the materials used in their construction, from traditional metals like bronze to advanced self-lubricating polymers and composites, which have expanded their application range. The text investigates various lubrication regimes, such as hydrodynamic, hydrostatic, and boundary lubrication, […]

How Does a Plain Bearing Work, and Why Does It Still Matter in Modern Industry?

How does a plain bearing work, and why do so many industrial systems still rely on this seemingly simple component? At its core, a plain bearing works by allowing relative motion between two surfaces through controlled sliding rather than rolling, using a lubricating film or self-lubricating material to reduce friction and wear. For B2B buyers, engineers, and procurement managers, understanding this working principle is essential because plain bearings remain critical in applications where load capacity, compact design, reliability, and cost efficiency outweigh the need for high rotational speed. Understanding the Fundamental Principle of Plain Bearings Plain bearings are among the oldest mechanical components, yet their operating principle remains highly relevant. […]

Where to Find High-Quality Plain Bearings for Industrial Applications?

Finding where to find high-quality plain bearings is not simply a sourcing question. For procurement managers, maintenance engineers, and OEM decision-makers, it is a strategic choice that directly affects equipment uptime, lifecycle cost, and operational safety. The short answer is this: high-quality plain bearings are sourced from experienced bearing suppliers with proven material expertise, strict manufacturing controls, recognized certifications, and application-driven engineering support. In practice, this means looking beyond price lists and focusing on suppliers who understand load profiles, lubrication regimes, environmental conditions, and long-term reliability. In the sections below, we explore how to identify reliable sources, what defines true bearing quality, and how industrial buyers can reduce risk while […]

What Does a Thrust Bearing Do and Why Is It Essential in Modern Machinery?

What does a thrust bearing do? In simple terms, a thrust bearing is designed to support axial loads, meaning forces that act parallel to the shaft. Unlike radial bearings, which handle loads perpendicular to rotation, thrust bearings prevent axial movement while allowing smooth rotational motion. This function is critical in machinery where components experience pushing or pulling forces along the axis, such as pumps, gearboxes, compressors, and automotive transmissions. By managing axial loads effectively, thrust bearings help maintain alignment, reduce friction, and extend the service life of mechanical systems across a wide range of industries. Understanding Axial Load and Why It Matters Axial load is a force that pushes or […]

Expert Guide 2026: What is a Roller Bearing & 5 Selection Criteria

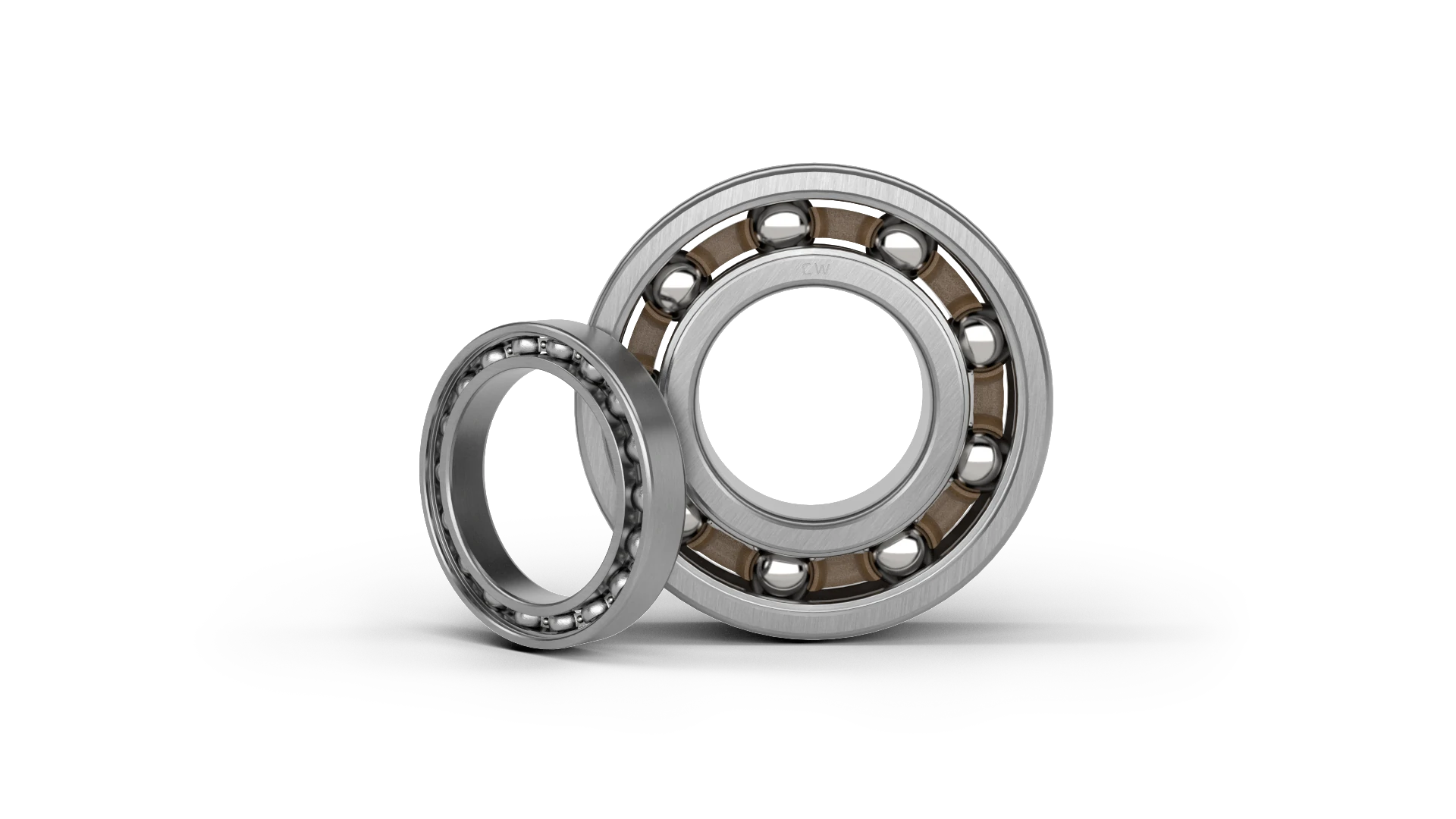

Abstract A roller bearing is a mechanical component designed to reduce rotational friction and support loads by using cylindrical or other non-spherical rolling elements. These elements are situated between two rings, or raceways, to facilitate the movement of machine parts. Unlike ball bearings, which use point contact, roller bearings utilize line contact, enabling them to support significantly higher radial loads, making them indispensable in heavy-duty machinery and industrial applications. This increased load capacity, however, often comes at the cost of lower speed capabilities. Different designs, such as cylindrical, spherical, tapered, and needle roller bearings, are engineered to accommodate specific load types, including radial, axial (thrust), or a combination of both, […]

An Expert’s Guide to What is a Linear Bearing: 5 Key Factors for 2025 Industrial Applications

Abstract A linear bearing is a mechanical component designed to enable free motion in a single direction along a straight path. This analysis examines the fundamental principles, construction, and diverse typologies of these crucial machine elements. The primary function of a linear bearing is to reduce friction and support a load during linear movement, distinguishing it from rotational bearings which facilitate circular motion. The investigation delves into the core components, including rolling elements like balls or rollers, raceways, and retainers, and explores the material science that governs their performance and durability. A central part of this exploration involves a comparative study of the main categories: rolling element bearings, which utilize […]

Expert Guide: 5 Step-by-Step Methods for How to Press a Bearing Flawlessly in 2025

Abstract The proper installation of rolling-element bearings is a fundamental determinant of their operational lifespan and the reliability of the machinery in which they are installed. This document provides a comprehensive examination of the methodologies for pressing a bearing, a process that, while seemingly straightforward, is fraught with potential for error that can lead to premature failure. It explores the underlying principles of interference fits, the critical importance of preparation, cleanliness, and the selection of appropriate tools. Five distinct mounting methods are analyzed in depth: mechanical cold mounting using presses and fitting tools, thermal mounting (shrink-fitting) via induction heating, hydraulic mounting for large-scale applications, specialized techniques for tapered bores, and […]

-

Professional Bearing Solutions for You

標準サイズからカスタマイズ仕様まで、最高品質の製品と迅速な対応でお客様のプロジェクトをサポートいたします。

-

メッセージを残す

あなたのプライバシーを守ります

私たちは100%の機密性を保証します。お客様の情報が共有されたり、最高のサービスを提供する以外の目的で使用されたりすることは決してありません。