Напречен хидростатичен лагер

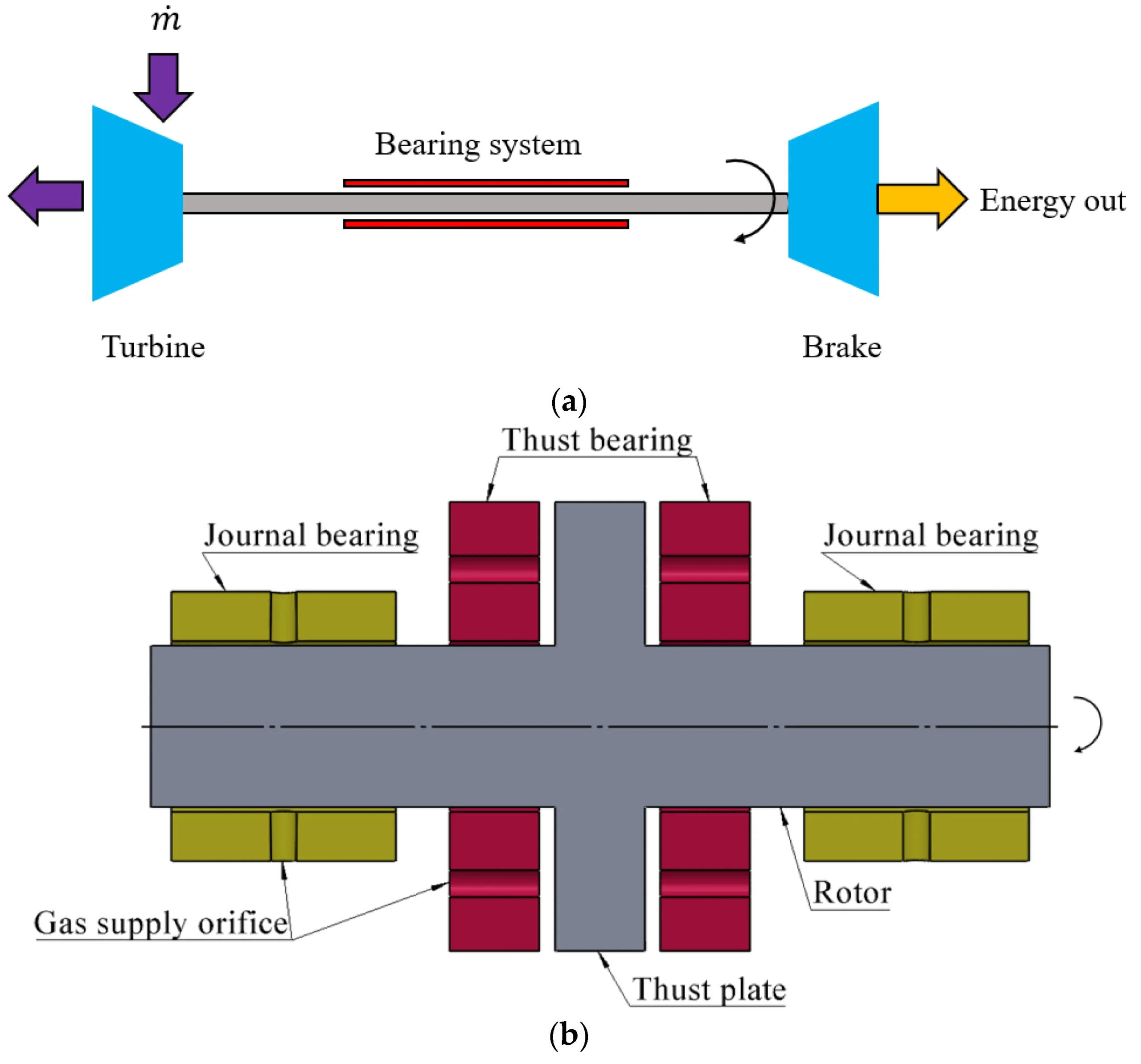

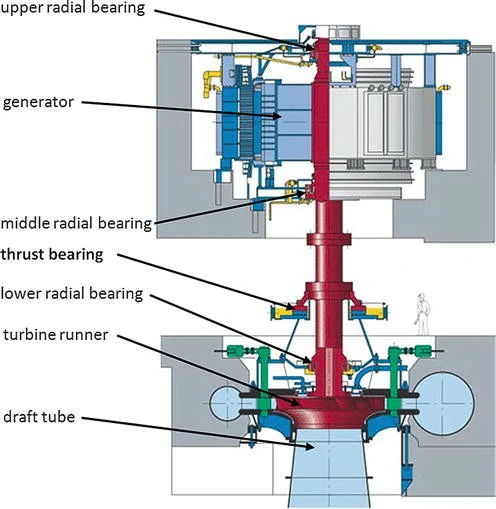

Thrust hydrostatic bearing is a bearing device that relies on an external fluid supply system to form fluid pressure. It separates the bearing surface from the load contact area through a fluid film to achieve low friction, high load, and high precision operation.

Application scenarios

Machining equipment: CNC machine tools, grinders, lathe spindles.

Energy equipment: turbines, water turbines, wind turbines.

Precision instruments: astronomical telescopes, high-precision measuring equipment.

Industrial machinery: large water pumps, compressor thrust bearings.

Advantages and characteristics

Low friction: Liquid film isolation, significantly reducing wear.

High load: can withstand heavy loads and run smoothly.

High precision: uniform liquid film, small operating error.

Long life: non-contact design, reduced loss.

Good heat dissipation: fluid circulation takes away heat and the temperature is stable.

Thrust hydrostatic bearing overview

Thrust hydrostatic bearings use an external pressure supply system (usually hydraulic oil or water-based medium) to deliver high-pressure fluid to form a stable oil film between friction pairs to achieve effective load transfer. This structure is designed for high-precision, heavy-load and low-friction working conditions.

Main application areas

According to the usage scenarios and structural characteristics, Thrust hydrostatic bearing can be divided into the following categories:

Industrial processing equipment

CNC machining center (CNC)

Precision grinder and lathe spindle unit

Energy power device

Steam turbine and gas turbine

Core components of wind turbine

Hydraulic generator bearings

Scientific research and testing instruments

Astronomical observation equipment

Precision experimental instruments

Transportation system

Ship power transmission mechanism

Key components of rail transit

Fluid machinery components

Large pump thrust components

Industrial compressor core bearings

Main brands:

SKF Thrust hydrostatic bearings

NSK Thrust hydrostatic bearings

FAG Thrust hydrostatic bearings

INA Thrust hydrostatic bearings

KOYO Thrust hydrostatic bearings

NACHI Thrust hydrostatic bearings

NTN Thrust hydrostatic bearings

TIMEKN Thrust hydrostatic bearings

Core performance advantages

Precision operation characteristics

The uniform fluid film layer can effectively compensate for the deformation of the working surface and ensure the operation accuracy.

Excellent load-bearing characteristics

The fluid lubrication mechanism avoids direct metal contact, and has both low friction coefficient and high load capacity.

Extremely long service life

The non-contact design greatly reduces mechanical wear and extends the service life.

Excellent thermal stability

The circulating fluid can take away heat in time to maintain the temperature balance of the system.

Wide environmental adaptability

The moisture-resistant and high-pressure characteristics enable it to maintain stable performance under harsh working conditions.

ЧЕСТО ЗАДАВАНИ ВЪПРОСИ

What is the core difference between static pressure bearings and dynamic pressure bearings?

Static pressure type: Depends on the external pressure supply system, and the speed independence makes it particularly suitable for low-speed and heavy-load scenarios.

Dynamic pressure type: It needs to rely on the rotation of the shaft system to establish oil film pressure, which is more suitable for high-speed working conditions.

Media selection criteria?

It is recommended to use pure fluids with stable viscosity (such as special hydraulic oil or deionized water), and a filtering device must be equipped to ensure the cleanliness of the media.

Daily maintenance points?

Regularly monitor the working status of the pressure supply system

Replace failed filter elements and deteriorated media in time

Adaptability to high temperature environments?

By selecting high temperature resistant medium and integrating cooling unit, the requirements of high temperature working conditions can be met.

Economic analysis?

Although the initial investment is high, the comprehensive economic benefits are significant due to the ultra-long service life and extremely low maintenance cost.