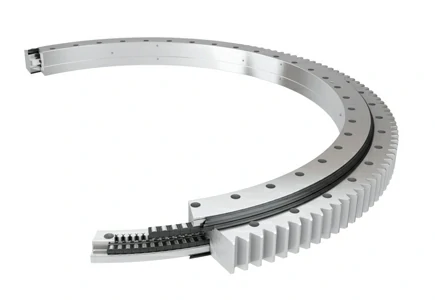

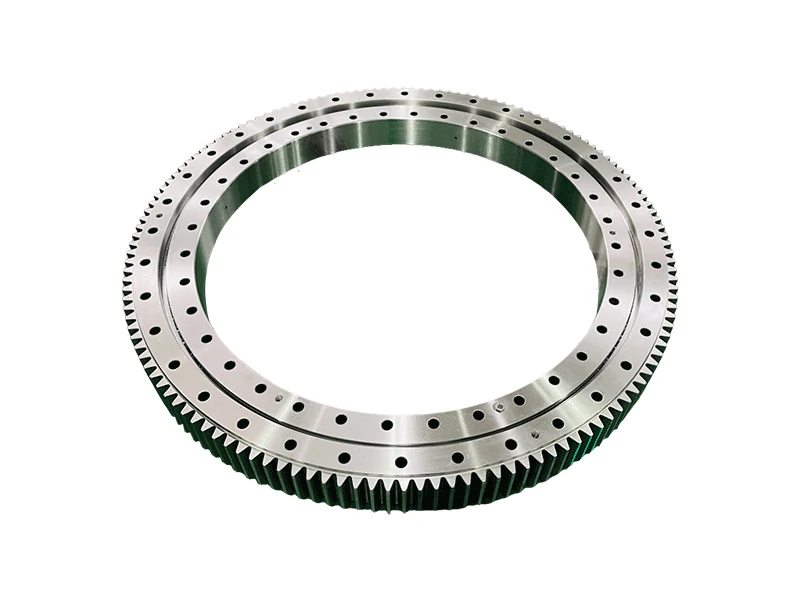

Триредни комбинирани цилиндрични ролкови лагери

Advantages and features

High load capacity

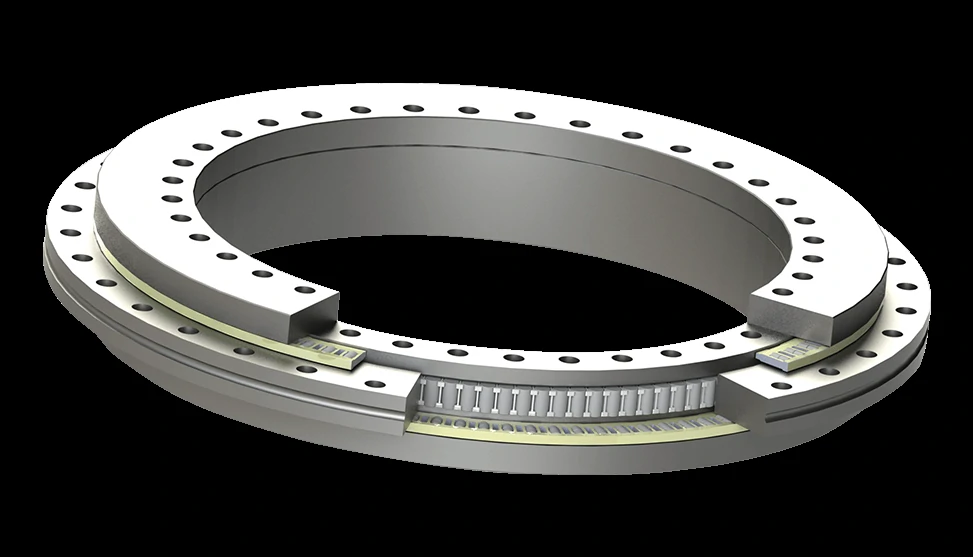

The three-row roller design greatly increases the contact area and can withstand large axial, radial and overturning moments at the same time.

Excellent stability

Through the precise matching of multiple rows of rollers, the bearing can effectively reduce shaking and improve operating stability during operation.

High efficiency and long life

The roller arrangement is optimized, the contact stress is evenly distributed, which reduces local wear and extends the service life.

Compact structure

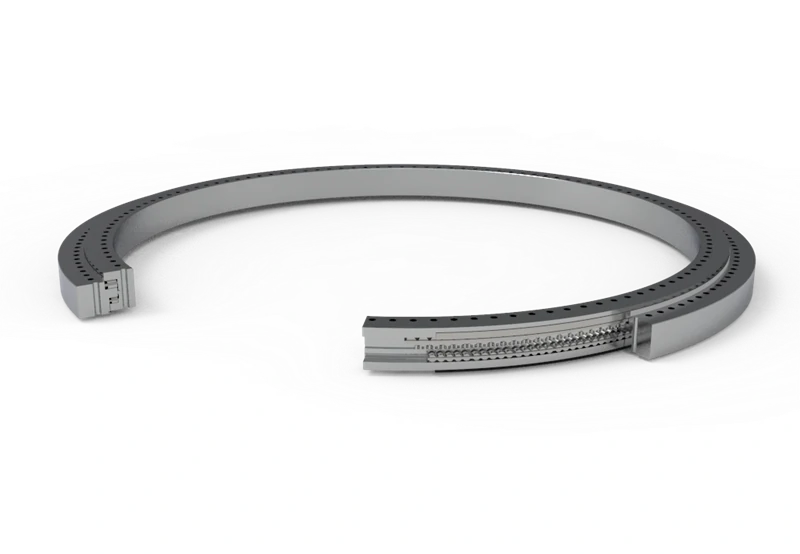

While meeting high loads, it occupies a small space and is suitable for design requirements of limited installation space.

Easy maintenance

The decomposable design is easy to disassemble and lubricate, and reduces downtime.

This type of bearing is widely used in engineering machinery, wind power equipment, metallurgical machinery and other industries, and is particularly suitable for high load, high precision and heavy working conditions.

See more at Лагери с въртящ се пръстен Catalog.

Technical analysis of three-row cylindrical roller combination bearings

Преглед на продукта

Three-row cylindrical roller combination bearings are a high-load, high-stability bearing system that uses a three-row independently arranged cylindrical roller structure to simultaneously cope with radial force, axial force and overturning moment. Its modular design makes it an important position in the heavy industry field, especially suitable for extreme loads and harsh working conditions.

Main application areas

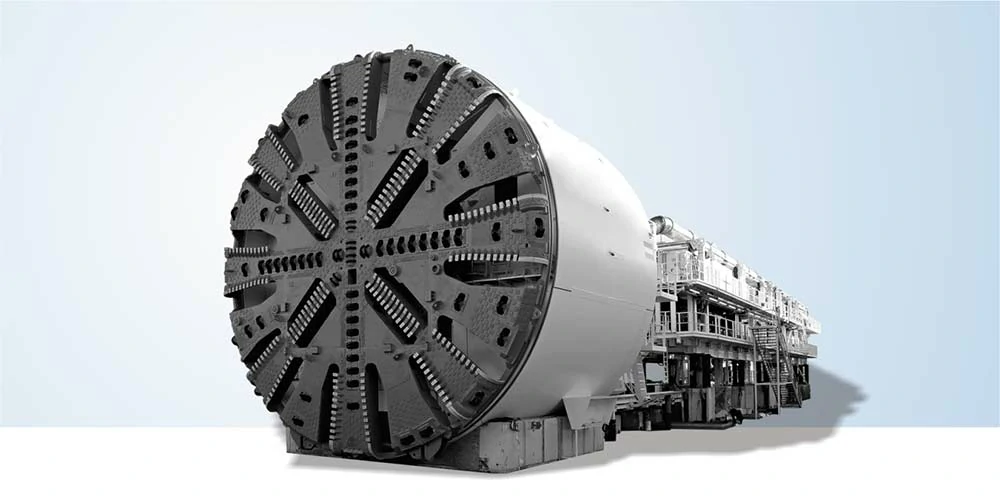

Heavy engineering equipment

Slewing mechanism of shield machines, port cranes, and mining excavators.

Clean energy equipment

Main shaft support unit of wind turbines.

Industrial processing machinery

High-load roller system of large rolling mills and continuous casting production lines.

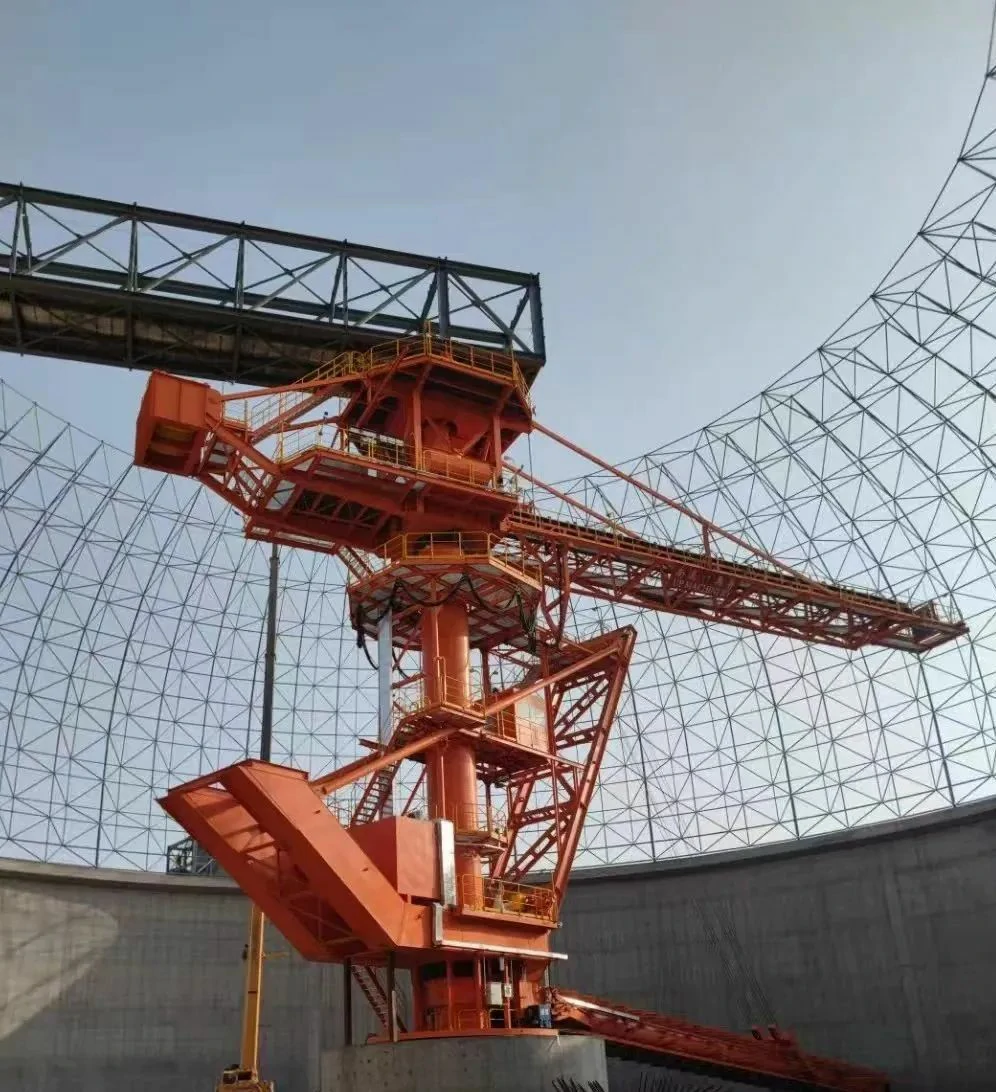

Material handling system

Rotary platform of automated warehousing equipment.

Core advantages and performance characteristics

Key advantages

Excellent load capacity

Three rows of rollers share stress synergistically, which improves the load-bearing efficiency by more than 50% compared with traditional single/double row bearings.

Strong dynamic stability

The multi-row structure effectively suppresses vibration and ensures smooth operation of the equipment under impact loads.

Low maintenance cost

Optimized sealing design and long-term lubrication scheme greatly reduce the frequency of downtime maintenance.

High space utilization

Integrated design replaces multi-bearing combination and simplifies equipment structure.

Technical features

Detachable architecture: Some models support modular disassembly and assembly for easy on-site maintenance.

Adaptive lubrication system: Compatible with grease or circulating oil lubrication, adapt to high temperature and dusty environment.

Reinforced material process: Using special alloy steel or hybrid ceramic technology, the anti-micro-peeling performance is improved by 30%.

Comprehensive review

As the core transmission component of heavy machinery, the three-row cylindrical roller combination bearing shows irreplaceable performance advantages under extreme working conditions through a multi-dimensional load distribution mechanism. Its technical highlight is the deep integration of high rigidity, long life and compact design, providing a more reliable support solution for modern industrial equipment.

ЧЕСТО ЗАДАВАНИ ВЪПРОСИ

Q1: What are the core improvements of the three-row bearing compared to the double-row structure?

A: The addition of axial roller rows forms a three-dimensional load-bearing network, which increases the anti-overturning capacity to more than twice that of the traditional structure.

Q2: Is it suitable for high-speed scenarios with more than 1,000 revolutions per minute?

A: Due to limited design characteristics, it is recommended for medium and low speed heavy load applications. It is recommended to use double-direction angular contact bearings for high-speed applications.

Q3: What are the warning signs of bearing failure?

A: Mainly including abnormal torque fluctuations, temperature rise exceeding 15% (compared to the benchmark value), periodic blackening of lubricants, etc.

Q4: What are the key control items during installation?

A: The centering accuracy of the shaft system needs to be monitored (≤0.05mm/m), hammer installation is prohibited, and the preload force needs to be dynamically detected.

Q5: How to interchange with cross roller bearings?

A: Cross roller bearings are more suitable for multi-directional composite loads, while three-row bearings are more cost-effective in single-direction ultra-large load scenarios.