Твърд инкрустиран самосмазващ се лагер

Advantages and features

Self-lubricating and maintenance-free

No need to add lubricating oil or grease, reducing maintenance costs, suitable for difficult-to-lubricate or pollution-sensitive environments (such as food and pharmaceutical machinery).

High temperature resistance & extreme working conditions

Can work at -200°C~+300°C (or even higher), suitable for harsh environments such as high temperature, vacuum, corrosive media, etc.

Low friction & high wear resistance

Low friction coefficient (0.05~0.2), slower wear and longer life than traditional dry friction bearings.

Strong load-bearing capacity

Metal matrix (such as copper, steel) provides high mechanical strength, suitable for heavy load and impact load conditions.

Anti-pollution & anti-adhesion

Solid lubricating film prevents direct metal contact, reduces adhesive wear, and adapts to dusty, humid and other environments.

Energy saving and environmental protection

No need for lubricating oil, avoid pollution, and meet environmental protection requirements.

Wide applicability

Used in engineering machinery, metallurgy, automobile, aerospace and other fields, especially suitable for low-speed heavy load or reciprocating motion scenes.

See more at Сух лагер Catalog

Solid Inlaid self-lubricating bearing technology analysis

Solid Inlaid self-lubricating bearing is a high-performance bearing designed with a solid lubricant and a metal matrix, which can achieve long-term stable operation in oil-free or harsh working conditions. Its core advantage lies in its self-lubricating properties, which are suitable for industrial scenarios with high loads, low speeds, high temperatures or difficult maintenance.

1. Composition and material properties

Bearing substrate:

High-strength alloys (such as bronze and steel-backed composite materials) are mostly used to ensure mechanical strength and impact resistance.

Solid lubrication phase:

Materials such as graphite, polytetrafluoroethylene (PTFE) or molybdenum disulfide (MoS₂) are uniformly embedded to form a protective transfer film during friction.

Enhanced design:

Some products add ceramic particles or fibers to improve wear resistance and pressure resistance.

2. Lubrication mechanism

Automatic lubrication:

When the bearing is running, the embedded lubricant gradually precipitates due to friction, forming a low-friction protective layer on the contact surface.

Continuous compensation:

The lubricating film is dynamically updated with wear to achieve long-term maintenance-free operation.

3. Key performance advantages

Oil-free operation: eliminates the need for lubrication systems and reduces maintenance complexity.

Environmental tolerance: adapts to a wide temperature range (-200℃~+300℃), is corrosion-resistant and dust-proof.

High-efficiency friction reduction: the friction coefficient is as low as 0.05~0.15, reducing energy loss.

High load capacity: static load can reach more than 200MPa, and dynamic load adaptability is strong.

Long service life: especially suitable for low-speed heavy load or intermittent motion conditions.

4. Typical application scenarios

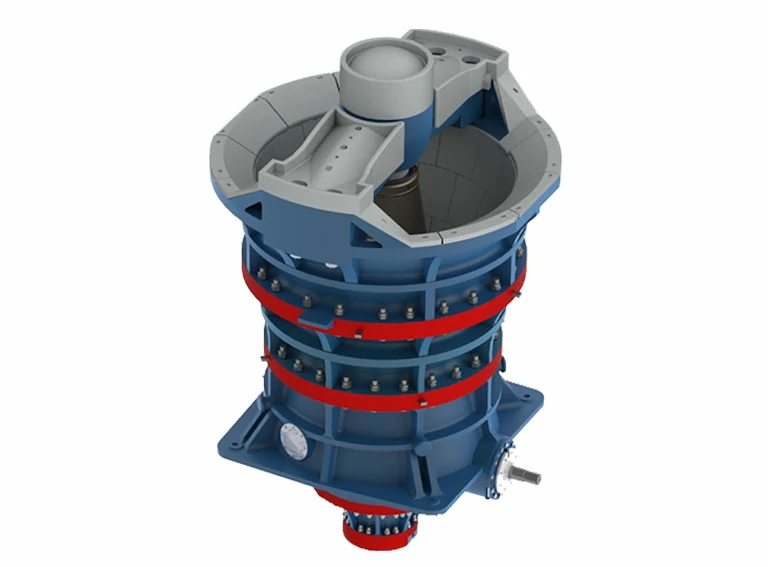

Heavy industry: continuous casting machine guide device, mining crushing equipment.

Transportation: truck suspension system, rail vehicle joint bearings.

Special environment: spacecraft deployment mechanism, deep-sea equipment pressure-resistant components.

Clean field: food processing equipment, medical equipment oil-free transmission components.

Общоприети марки

SKF Solid Inlaid self-lubricating bearing

NSK Solid Inlaid self-lubricating bearing

FAG Solid Inlaid self-lubricating bearing

NTN Solid Inlaid self-lubricating bearing

KOYO Solid Inlaid self-lubricating bearing

INA Solid Inlaid self-lubricating bearing

TIMKEN Solid Inlaid self-lubricating bearing

NACHI Solid Inlaid self-lubricating bearing

5. Common types and optimized designs

Regular embedded type: Lubricants are distributed in a specific geometric pattern (such as honeycomb).

Gradient composite type: The surface layer of the matrix contains high-concentration lubricants, and the internal mechanical properties are enhanced.

Customized working conditions: Adjust the lubricant ratio and arrangement density according to pressure, speed and medium.

6. Comparison with traditional bearings

Parameters Embedded self-lubricating bearings Conventional lubricating bearings

Lubrication dependence Completely self-lubricating Requires regular addition of grease or lubricant

Adaptability to extreme working conditions Excellent (vacuum, high and low temperature, etc.) Limited (oil film is prone to failure)

Comprehensive maintenance cost Significantly reduced High (labor and consumables costs)

Failure risk No oil film rupture problem Depends on the integrity of the oil film

7. Selection and installation points

Working condition matching: Low speed and high load have the best effect, and high speed requires auxiliary heat dissipation design.

Material adaptation: Graphite-based is preferred for high temperature environment, and PTFE composite type is selected for chemical corrosion environment.

Fitting accuracy: It is recommended to use clearance fit (such as H7/g6) to avoid interference and lubricant blockage.

Assembly direction: Ensure that the lubricant release surface is in contact with the friction surface.

8. Usage and maintenance recommendations

Regularly clean the residual particles of the friction pair (non-metal scraper or non-destructive cleaning).

For strong acid and alkali environments, a chemical corrosion-resistant coating version should be selected.

In the initial running-in period, lubricating paste can be pre-applied to accelerate the formation of a protective film.

Solid Inlaid self-lubricating bearings break through the reliance of traditional bearings on liquid lubrication through composite materials and structural innovations, and perform excellently in complex working conditions. In actual applications, it is necessary to combine specific parameters (such as PV limit, environmental medium) for targeted selection to give full play to its technical advantages.