Mounted Roller Bearings

Предимства и функции

High load capacity

Roller bearing design can withstand higher radial and axial loads than ball bearings.

Strong impact resistance

Suitable for industrial scenarios with large vibration and impact loads.

Self-aligning function (applicable to spherical roller bearings)

Allows slight axial deflection to maintain operational stability.

Дълъг експлоатационен живот

Optimizes roller contact stress, reduces wear, and extends bearing service life.

Easy to install

Modular design, pre-assembled bearings and seats, simplifying the installation process.

Adaptable to harsh environments

Equipped with an efficient sealing structure, it has dustproof, waterproof and high temperature resistance.

Easy to maintain

Relubricable design to extend equipment operation time and reduce downtime.

Mounted Roller Bearings: Comprehensive Overview

Mounted roller bearings are specialized bearing units that integrate roller bearings (e.g., spherical, cylindrical, or tapered roller bearings) with bearing housings (e.g., pillow block, flange, or take-up housings). These bearings are known for their high load capacity, strong impact resistance, and long service life, making them indispensable in industries such as mining, metallurgy, paper production, and heavy machinery.

1. Applications and Detailed Use Cases

(1) Mining and Metallurgical Equipment

Examples: Crushers, ball mills, rolling mills.

Benefits: Handles heavy impact loads, resistant to high temperatures and contaminants.

(2) Paper and Printing Machinery

Examples: Calenders, paper reels, coating machines.

Benefits: Operates at high speeds while minimizing vibrations.

(3) Heavy-Duty Conveyor Systems

Examples: Chain conveyors, bucket elevators.

Benefits: Supports heavy rollers, reduces friction and wear.

(4) Construction Equipment

Examples: Excavators, cranes, concrete pump trucks.

Benefits: Vibration resistance, dustproof, and waterproof capabilities for harsh environments.

(5) Energy and Power Equipment

Examples: Wind turbines, hydraulic turbines.

Benefits: High reliability, reduced maintenance demands.

Common Brands

SKF Mounted Roller Bearings

NSK Mounted Roller Bearings

FAG Mounted Roller Bearings

INA Mounted Roller Bearings

NTNMounted Roller Bearings

TIMKEN Mounted Roller Bearings

KOYO Mounted Roller Bearings

NACHI Mounted Roller Bearings

2. Features and Advantages

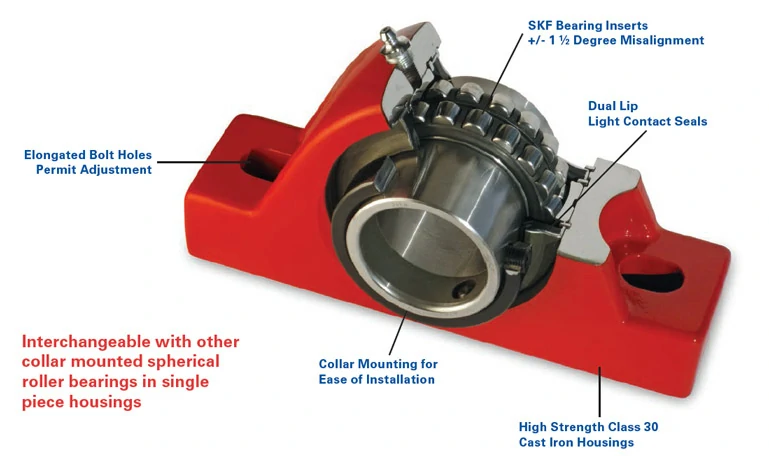

(1) Structural Features

Modular Design: Pre-assembled bearing and housing for easy installation.

Versatile Roller Types:

Сферични ролкови лагери: Self-aligning, accommodates misalignment.

Цилиндрични ролкови лагери: High radial load capacity.

Конусни ролкови лагери: Combined radial and axial load handling.

Various Housing Options:

Pillow Block Housings: General-purpose, for horizontal shafts.

Flange Housings: Space-saving design for vertical mounting.

Take-Up Units: Adjustable for belt tensioning.

(2) Performance Advantages

Advantages Details

High Load Capacity Outperforms ball bearings under heavy loads.

Impact Resistance Suitable for vibration-intensive and impact-prone environments.

Long Service Life Optimized roller stress distribution minimizes wear.

Maintenance Friendly Relubricable design reduces downtime.

Environment-Ready Dustproof, waterproof, and high-temperature resistant.

3. Frequently Asked Questions (FAQs)

Q1: How to choose between mounted roller bearings and ball bearings?

Roller Bearings: Ideal for heavy loads and impact (e.g., mining, metallurgy).

Ball Bearings: Better for medium/light loads and high speeds (e.g., conveyors, food machinery).

Q2: What distinguishes self-aligning roller housings from standard housings?

Self-Aligning Housings: Accommodates slight shaft misalignments; suitable for long shafts and flexible conditions.

Standard Housings: Higher rigidity; best for short, well-aligned shafts.

Q3: How to identify when a mounted roller bearing needs replacement?

Abnormal noises (metallic grinding, irregular vibrations).

Excessive temperature rise (above 80°C indicates lubrication issues).

Increased internal clearance (affects operational accuracy).

Damaged seals (leads to grease leakage or contamination ingress).

Q4: How to correctly install mounted roller bearings?

Avoid direct hammering; use hydraulic or heating methods.

Ensure proper shaft-to-housing fit, avoiding tight or loose assembly.

Lubricate adequately before first operation.

Q5: Are mounted roller bearings suitable for high-speed applications?

Generally not recommended. These bearings are better for medium to low speeds and heavy loads. For high-speed requirements, consider mounted angular contact ball bearings.

4. Summary and Key Takeaways

Mounted roller bearings are core components in heavy industries, offering unmatched load capacity, impact resistance, and durability. These bearings are the preferred choice for extreme working conditions but require precise installation and regular maintenance for optimal performance.

Recommended Applications:

✔ High-load and high-impact environments (e.g., crushers, rolling mills).

✔ Long-shaft operations requiring self-alignment (e.g., conveyors, fans).

✔ Harsh environments (e.g., dusty, humid, or high-temperature conditions).