FAG Bearing

We have a complete supply chain to provide FAG bearing products and bring customers a high-quality experience. If you have any related needs, please consult the product information and we will give you a reasonable quotation. Looking forward to your message and email.

Historical Background

FAG's origins date back to the late 19th century, when founder Friedrich Fischer's pioneering ball grinding technology laid the foundation for the modern bearing industry. Today, as a core brand of the Schaeffler Group, FAG upholds the German tradition of precision engineering, providing critical components for demanding applications such as aerospace and high-end industrial equipment.

Founding Milestone (1883)

German engineer Friedrich Fischer established the company in Schweinfurt, where he invented the world's first industrial ball grinding machine. This breakthrough enabled mass production of steel balls with geometric precision, laying the foundation for standardized bearing manufacturing.

Technological Revolution (1890s-1900s)

Fischer obtained a patent for his ball grinding machine in 1890, solving the critical challenge of controlling spherical tolerance. In 1905, the company was officially named FAG (Fischer's Automatische Gusstahlkugelfabrik), becoming the world's first specialized bearing manufacturer.

Pioneering Contributions

- Developed the first spherical roller bearing in 1913

- Established Europe's first dedicated bearing testing center in the 1920s

- Participated in formulating German Industrial Standards (DIN) for bearings in 1937

Modern Evolution

After merging into the Schaeffler Group in 2001, FAG maintains independent brand operation. Its original factory location in Schweinfurt remains a global hub for bearing R&D, housing a historical technical archive.

FAG's origin represents the beginning of precision manufacturing standardization. Its early innovations continue to form the theoretical foundation for bearing geometry and materials science. The company still upholds its founder's philosophy of "precision to the micron" as its core technical principle.

Product Portfolio

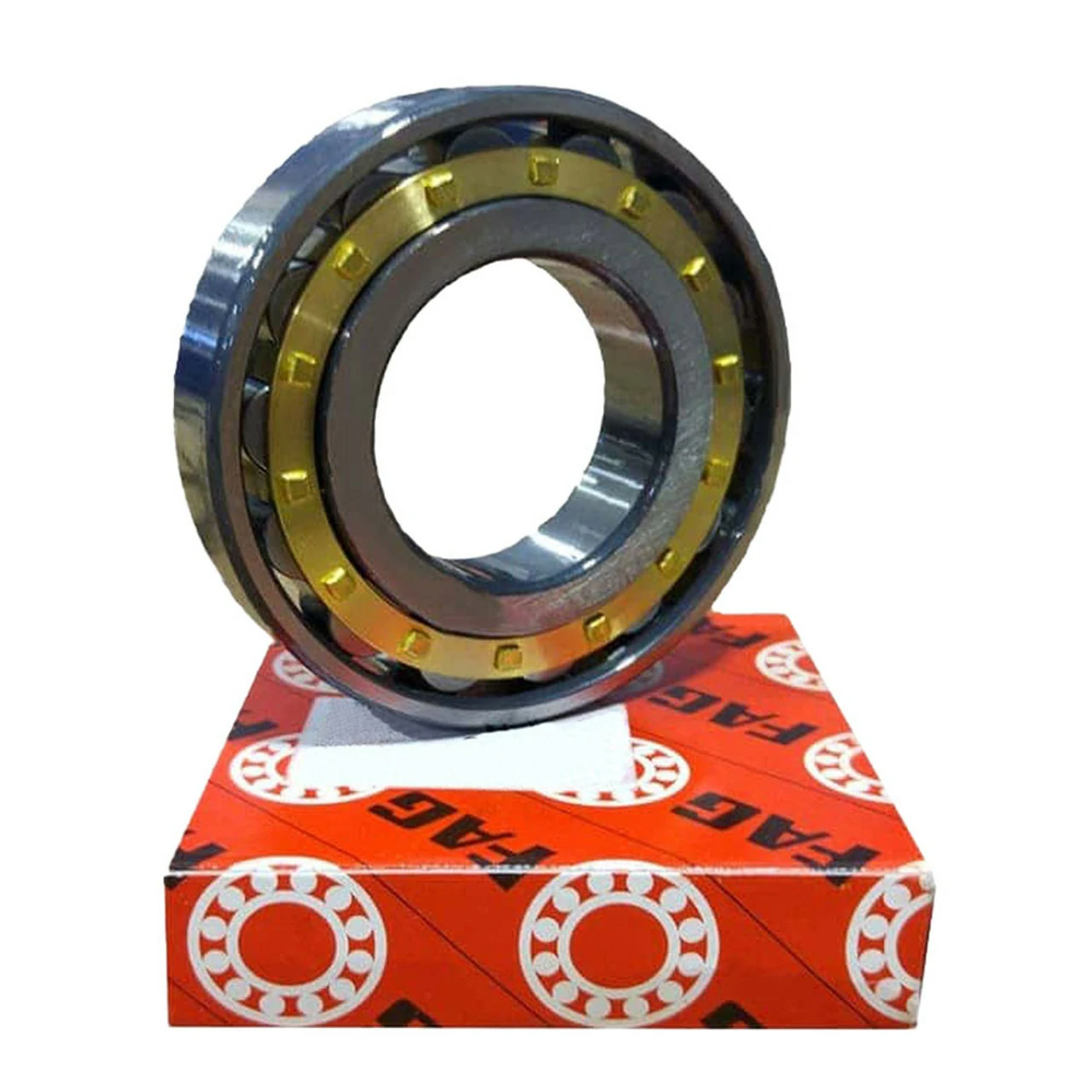

FAG's product portfolio includes:

-

FAG Ball Bearings: Ideal for high-speed applications, offering low friction and high precision.

-

FAG Roller Bearings: Designed for heavy-duty applications, including Цилиндрични ролкови лагери, Сферични ролкови лагери, and Taper Roller Bearings, providing robust performance under radial and axial loads.

-

FAG Needle Bearings: Suitable for applications with limited space, offering high load capacity.

-

FAG Insulated Bearings: Prevent electric currents from passing through the bearing, protecting against electrical erosion.

-

FAG Precision Bearings: Manufactured to stringent tolerances, ensuring high accuracy and reliability.

All FAG Bearings are built with durable SKF3 steel and adhere to ISO & DIN standards, ensuring longevity and consistent performance.

Technical Differentiation and Advantages

Utilization of ultra-clean steel combined with gradient heat treatment technology extends bearing fatigue life beyond industry standards;

The X-life technology platform employs topological optimization and surface engineering innovations to reduce friction torque by 15% and improve thermal management;

Comprehensive lifecycle management solutions integrate digital twins and intelligent lubrication systems to significantly enhance overall equipment efficiency;

Leveraging the Schaeffler Group's global supply chain enables 48-hour emergency response and customized delivery services.

FAG's core competitiveness lies in the deep integration of precision manufacturing and digital services. Through a dual-driven approach of "technology + service," it continuously creates incremental value for high-end manufacturing industries.

Technical Leadership

Pioneering Heritage: As the inventor of rolling bearing technology, FAG possesses over 140 years of technical expertise.

Continuous Innovation: Annual R&D investment representing approximately 5% of revenue maintains leadership in high-speed precision bearings.

Standard Setting: Active participation in developing international bearing standards (ISO, DIN).

Core Product Strengths

Comprehensive Precision Range: Covering from standard grades to P4S super-precision (accuracy up to 0.001mm).

Specialized Solutions: Expertise in extreme conditions (-200°C to +500°C), vacuum environments, and corrosive applications.

X-life Technology Platform: Optimized internal geometry design extends bearing service life by over 30%.

Market Position

Ranked among top three in European market share, exceeding 40% in German high-end manufacturing.

Global top-five patent holder in bearing industry with 2,000+ active patents.

Market leadership exceeding 35% in premium segments like machine tool spindles and aerospace bearings.

Service Capabilities

Global technical service network across 50 countries providing localized support.

Digital services featuring IoT-based predictive maintenance systems for early fault detection.

Rapid response system ensuring 48-hour emergency delivery worldwide.

FAG has established distinct competitive advantages in premium bearing markets through its "German Precision Engineering" brand reputation. Serving leading global enterprises including Siemens and ThyssenKrupp, the brand is widely recognized as the benchmark for reliability and precision in the most demanding industrial applications.

Comdale: Your Trusted FAG Bearing Manufacturer

Comdale stands as a professional supplier and authorized FAG bearing supplier, specializing in the production and supply of FAG Bearings. Our state-of-the-art manufacturing facilities and adherence to stringent quality control processes ensure that each bearing meets the precise specifications required by our clients.

With a focus on innovation and customer satisfaction, Comdale offers a wide range of FAG Bearings, including Spindle Bearings and Insulated Bearings, tailored to meet the diverse needs of industries worldwide.

Global Trust and Availability

We provide FAG Bearings in Stock for immediate deliver. Our products are trusted in over 100 countries, reflecting our commitment to quality and customer satisfaction.

OEM & ODM Support

We offer comprehensive OEM & ODM Bearing Support, catering to specific requirements and customizations. Our experienced team ensures that each bearing meets the highest standards of quality and performance.