Angular Contact Thrust Ball Bearing

Angular contact thrust ball bearings are high-performance bearings that can withstand both axial and radial loads. They provide high rigidity, low vibration and excellent high-speed performance through optimized contact angle design.

Main advantages:

High load capacity: taking into account both axial and radial loads.

Excellent high-speed performance: suitable for high-speed rotation conditions.

High precision and rigidity: ensure stable axial positioning and low-vibration operation.

Strong durability: long design life, adaptable to a variety of working environments.

Flexible installation: multiple models are available, suitable for a wide range of application scenarios.

Angular contact thrust ball bearing overview

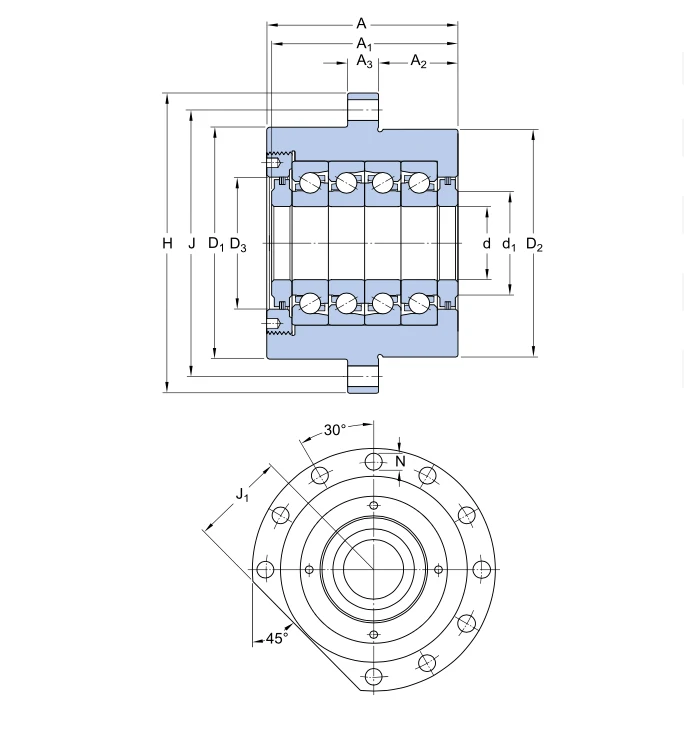

Thrust Angular Contact Ball Bearing is a specially designed bearing that can bear axial force and a certain degree of radial force at the same time. Its structure uses steel balls as rolling elements and achieves high stiffness and strong load performance with the help of specific contact angles of inner and outer rings. The value of the contact angle directly determines the load-bearing limit and speed adaptability of the bearing. Typical angles include 15°, 25° and 40°.

Main application scenarios

This type of Напречни сачмени лагери plays a key role in many industries:

Precision machine tools: used for spindle units to meet high-speed operation and high-precision requirements.

Aerospace: suitable for engines and navigation equipment, which need to cope with extreme loads and ensure stable operation.

Vehicle manufacturing: commonly seen in clutch release mechanisms and steering devices, relying on their axial support characteristics.

Heavy machinery: such as turbine equipment and air compressors, which need to ensure axial positioning stability.

New energy field: used in wind turbines to handle multi-directional dynamic loads.

Core performance advantages

Excellent load performance: can efficiently withstand axial and radial pressures at the same time.

High-speed adaptability: The optimized contact angle design enables it to perform well under fast rotation conditions.

Precision and stability: Provides precise axial positioning and effectively reduces operating vibration.

Strong durability: Uses high-quality materials and advanced manufacturing technology to significantly extend the service life.

Diverse configurations: Provides single-row, double-row and combined structures to adapt to different working environments.

Common Questions Analysis

Q: What is the difference between this type of bearing and conventional bearings?

A: Ordinary bearings can generally only handle loads in a single direction, while angular contact thrust Сачмени лагери can simultaneously cope with axial and radial composite forces.

Q: How to choose a suitable contact angle?

A: A larger contact angle enhances the axial load-bearing capacity and is suitable for heavy-load scenarios; a smaller angle is more conducive to high-speed operation requirements.

Q: What should be paid attention to in daily maintenance?

A: The lubrication status needs to be monitored regularly to ensure installation accuracy while preventing overload operation and abnormal vibration.

Q: Is it suitable for extreme temperature environments?

A: It is feasible, but it requires the use of special materials (such as ceramic balls) and special lubricants that are resistant to high and low temperatures.

Q: How to extend the service life of bearings?

A: Scientific lubrication, standardized loads and maintaining clean operating conditions can effectively extend the service life.