Радиални хидростатични лагери

Типични приложения

Свръхпрецизна обработка: шпиндели за наноравнище на металорежещи машини, шлифовъчни машини за оптични огледала

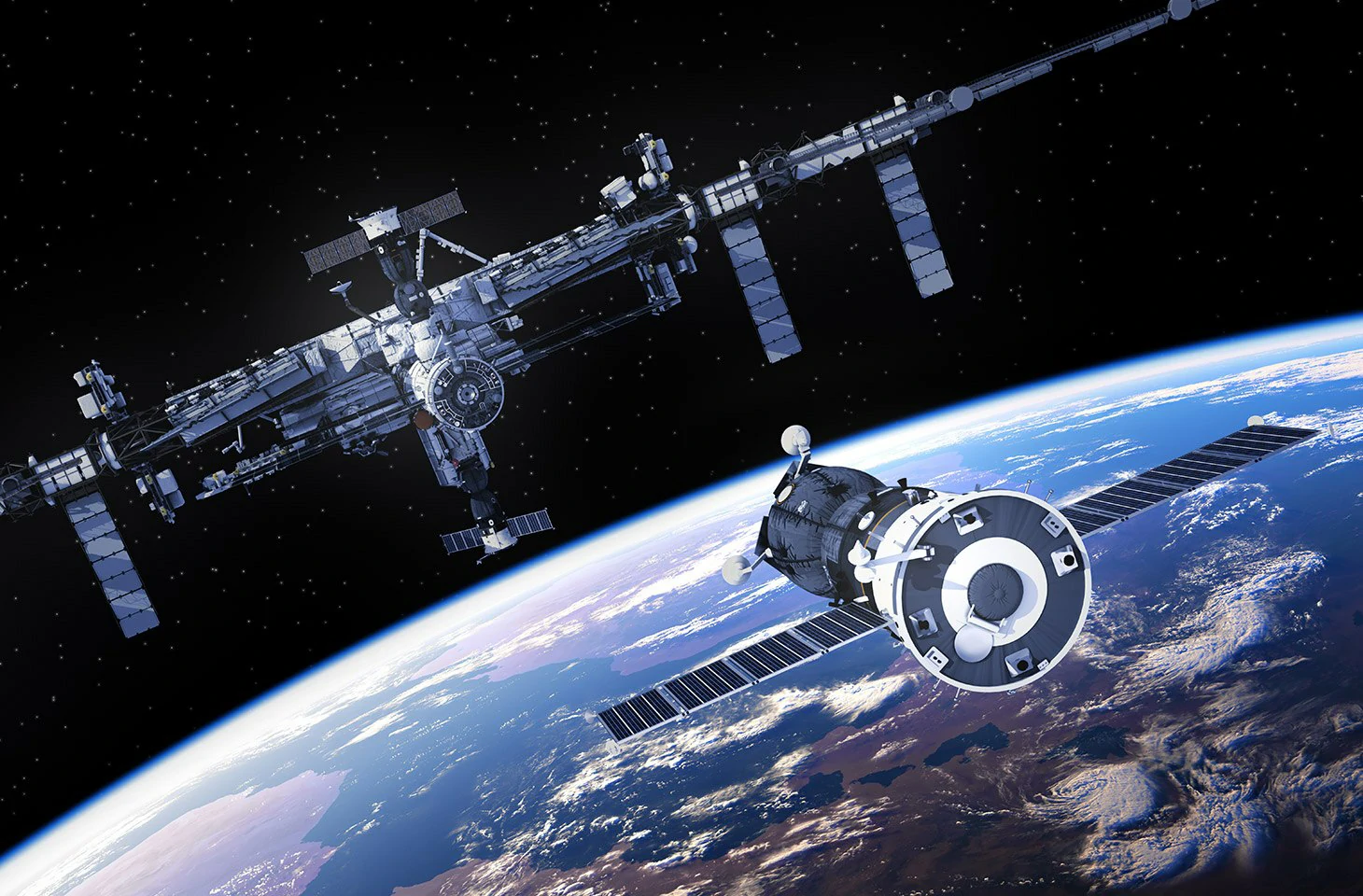

Космическа индустрия: лагери за контрол на положението на сателитите, стендове за изпитване на двигатели на самолети

Енергийно оборудване: големи хидроелектрически генератори, лагери на основни ядрени помпи

Научноизследователски инструменти: въртяща се маса за електронен микроскоп, лазерен интерферометър

Интелигентно производство: индустриален робот RV редуктор, оборудване за полупроводникови пластини

Основни предимства

Прецизност на ниво микрон: дебелината на масления филм се контролира прецизно (1-50 μm)

Свръхвисоко натоварване: капацитетът на натоварване на единица площ може да достигне 30MPa

Работа с нулево износване: теоретичният живот може да достигне повече от 100 000 часа

Потискане на вибрациите: присъщото затихване е 3-5 пъти по-високо от това на традиционните лагери

Отлична енергийна ефективност: консумацията на енергия от триене е намалена с повече от 90%

Адаптивност към околната среда: поддържа условия на висока температура от -196℃ (течен азот) до 300℃

Анализ на технологията на радиалните хидростатични лагери

Принцип на работа

Радиален хидростатични лагери използване на външно устройство за подаване на масло, за да се изтласка смазочната среда в междината на лагера и да се образува стабилен хидравличен маслен филм. Ефектът на статично налягане, генериран от масления филм, ефективно изолира контакта на триещата се двойка и постига работно състояние с почти нулево триене. Този безконтактен метод на поддържане е особено подходящ за промишлени сценарии със строги изисквания за прецизност и стабилност.

Общоприети марки

SKF Радиални хидростатични лагери

Радиален хидростатичен лагер FAG

INA Радиален хидростатичен лагер

NSK Радиален хидростатичен лагер

NTN Радиален хидростатичен лагер

TIMKEN Радиален хидростатичен лагер

Радиален хидростатичен лагер NACHI

KOYO Радиален хидростатичен лагер

Типични области на приложение

Прецизно производствено оборудване

Система за шпиндел на свръхпрецизни металорежещи машини

Механизъм за въртене на оборудване за шлифоване с висока точност

Аерокосмическо оборудване

Платформа за изпитване на авиационни двигатели

Устройство за контрол на положението на космическия кораб

Енергийна система

Големи компоненти за поддръжка на генератора

Механизъм за предаване на оборудване за дълбоководно сондиране

Инструменти за измерване и откриване

Оборудване за оптично откриване на нано ниво

Въртяща се маса за прецизни метрологични инструменти

Интелигентна система за оборудване

Прецизни стави за индустриални роботи

Предавателен модул на автоматизирана производствена линия

Основни технически предимства

Прецизност на нано ниво: Поддръжката на маслен филм елиминира механичния контакт и постига субмикронна точност на работа

Отлична носеща способност: Хидравличната система може да осигури опорно налягане до 100MPa

Изключително гладка работа: Демпфериращият ефект на масления филм ефективно потиска вибрациите, а работният шум е под 40 dB

Характеристики на свръхниска консумация на енергия: Коефициентът на триене е едва 0,001, а ефектът на енергоспестяване е Значителни резултати

Изключително дълъг експлоатационен живот: безконтактната конструкция увеличава експлоатационния живот 5-8 пъти

Адаптивност към околната среда: може да работи стабилно в широк температурен диапазон от -50 ℃ до 200 ℃

Общи решения за отстраняване на неизправности

Проблем с повредата на масления филм

Причина: необичайно налягане на подаване на масло или блокиране на маслената верига

Мерки за противодействие: инсталиране на устройство за следене на налягането и редовно почистване на масления кръг

Влошаване на ефективността на смазване

Причина: замърсяване или влошаване на качеството на маслото

Мерки за противодействие: създаване на система за редовна проверка на маслото и приемане на многостепенна система за филтриране

Необичайно повишаване на температурата

Причина: недостатъчно охлаждане или работа при претоварване

Мерки за противодействие: оптимизиране на дизайна на охладителната система и инсталиране на алармено устройство за температурата

Вибрациите надвишават стандарта

Причина: отклонение на монтажа или несъответствие на параметрите на масления филм

Мерки за противодействие: използвайте инструмент за лазерно подравняване, за да калибрирате и регулирате параметрите на дебелината на масления филм

Техническо резюме

Радиалните хидростатични лагери, един от плъзгащи лагери, със своята революционна технология за безконтактна поддръжка, показаха незаменими предимства в областта на производството на високотехнологично оборудване. Тази технология перфектно решава индустриалния проблем за висока точност, високо натоварване и дълъг живот чрез прецизно контролиран хидравличен маслен филм. Нейните експлоатационни предимства са особено видни в най-модерните области като прецизната обработка и космическата индустрия. Разумното проектиране на системата, съчетано с научни планове за поддръжка, може да поддържа производителността на лагерите в най-добро състояние по всяко време, осигурявайки надеждна техническа поддръжка на съвременното промишлено оборудване.