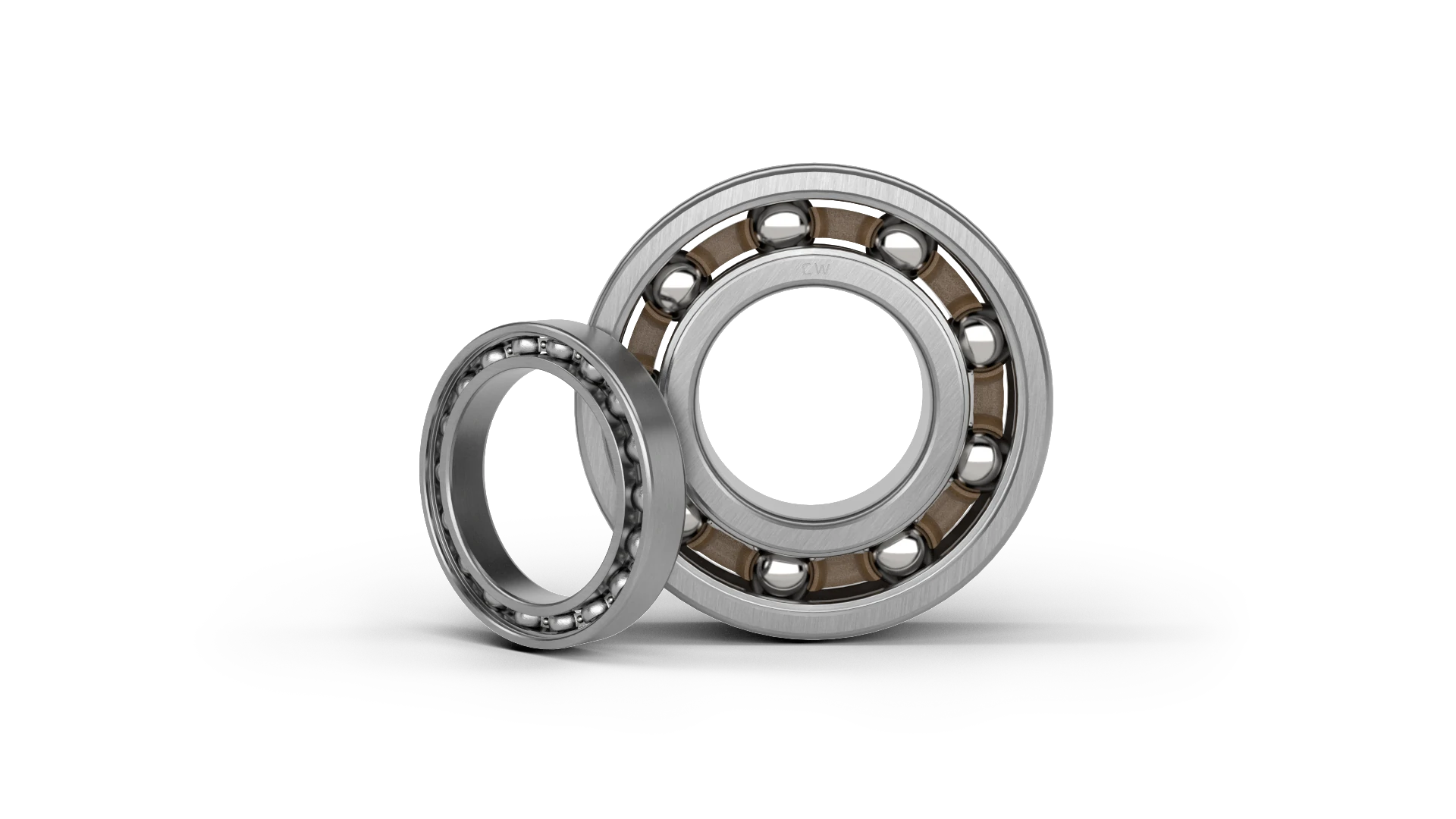

Шариковые подшипники с четырехточечным контактом

Приложения:

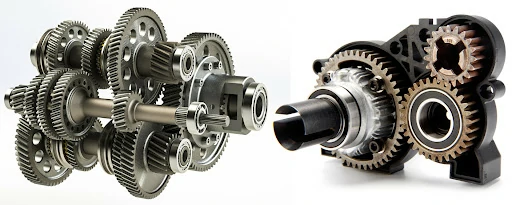

Machine tool spindle (high-speed precision machining).

Industrial robots (joint parts).

Aerospace (gearbox, transmission system).

Automotive steering system (electric power steering).

Compressor/pump (high axial load occasions).

Advantages and features:

Bidirectional load: a single bearing can withstand bidirectional axial forces, simplifying the design.

High rigidity: four-point contact structure enhances load distribution and reduces deformation.

High-speed performance: optimized raceway design, suitable for high-speed rotation.

Compact design: replace double-row bearings to save space.

High precision: suitable for equipment with strict requirements on rotation accuracy.

Suitable for occasions requiring high load capacity, high rigidity and compact layout.

Technical analysis of four-point angular contact ball bearings

Product Overview

Four-point angular contact ball bearings adopt a unique four-point contact design. By optimizing the raceway geometry, the single-row steel ball forms four contact points with the inner and outer rings. This innovative structure enables it to have bidirectional axial load capacity and can withstand significant radial loads, and performs well in high-performance applications with limited space.

Core features

Multi-directional load-bearing advantage

Synchronously bear bidirectional axial and radial forces

Axial load capacity is increased by more than 35% compared with standard angular contact bearings

Space optimization design

Single-row structure realizes double-row bearing function

Cross-section height is reduced by 20%, suitable for compact equipment

Precision motion control

Contact angle is optimized to 35° to achieve low vibration operation

Rotation accuracy can reach P4 level (ABEC7)

High performance

Limiting speed is 15-20% higher than ordinary bearings

Special cage design reduces friction temperature rise

Распространенные бренды

SKF four-point angular contact ball bearings

NSK four-point angular contact ball bearings

NTN four-point angular contact ball bearings

FAG four-point angular contact ball bearings

KOYO four-point angular contact ball bearings

INA four-point angular contact ball bearings

TIMKEN four-point angular contact ball bearings

NACHI four-point angular contact ball bearings

Typical technical parameters

Typical application scenarios

Precision transmission system

CNC machine tool electric spindle adopts ceramic hybrid four-point contact bearing to achieve 20,000rpm ultra-high-speed cutting

New energy equipment

Photovoltaic tracking system is equipped with sealed four-point contact bearings, which can withstand temperature changes from -30℃ to 80℃

Intelligent logistics equipment

Automated sorting line turntable bearings integrate four-point contact design to achieve a high cycle life of 2 million times/year

Special vehicles

Military off-road vehicle wheel hub units adopt reinforced four-point contact bearings, and the impact load capacity is increased by 50%

Technical questions and answers

Q1 What are the advantages compared with cross roller bearings?

Four-point contact ball bearings have a 40% lower friction coefficient, which is more suitable for high-speed scenarios and has lower maintenance costs.

Q2 Extreme operating temperature range?

Standard type: -30℃~120℃

High temperature type (special heat treatment): -50℃~150℃

Q3 Preload adjustment suggestions?

The axial clearance is controlled at 0.02-0.05mm, and interference fit will significantly affect the bearing life

Q4 Failure warning indicator?

When the vibration value is greater than 4.5mm/s or the temperature rise is greater than 15℃, the machine should be stopped for inspection immediately

Technical summary

The four-point angular contact ball bearing perfectly solves the problem of coordinated bearing of bidirectional axial load and radial load through an innovative four-point contact mechanical model. With the development of material surface treatment technology (such as DLC coating) and intelligent lubrication system, its application in cutting-edge fields such as aerospace and precision medical equipment continues to expand, becoming the core component of modern precision transmission systems.