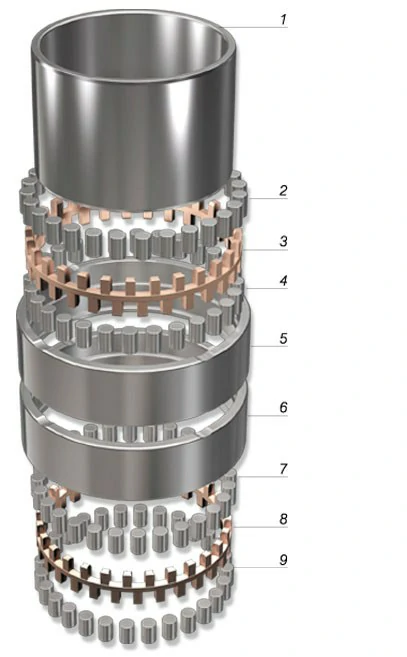

четырехрядный сферический роликовый подшипник

Main applications

Heavy industry: rolling mills, continuous casting machines

Mining machinery: crushers, vibrating screens

Papermaking equipment: drying cylinders, calendering rollers

Textile machinery: spinning machines, looms

Reducers and gearboxes: high-load transmission systems

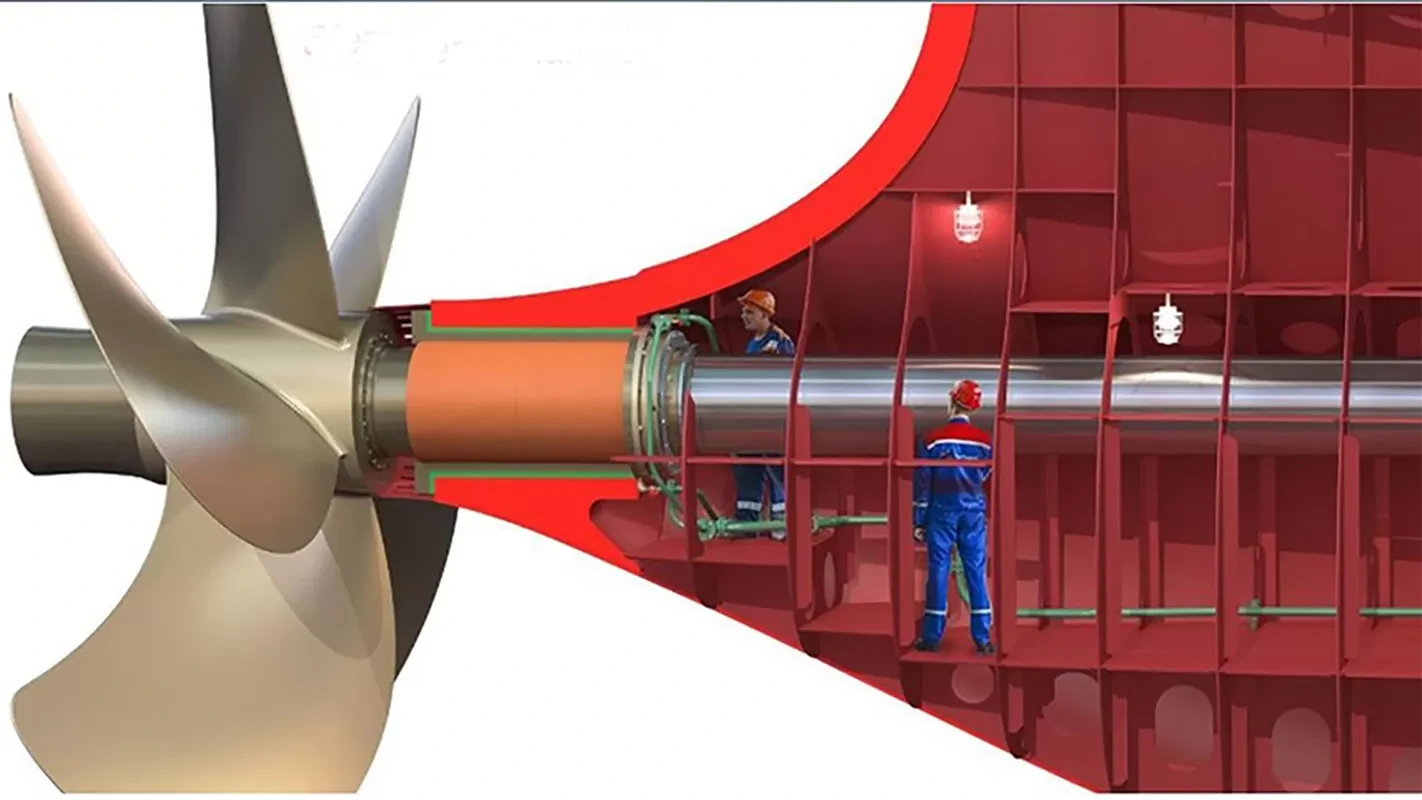

Ship propulsion: propeller shaft support

Основные преимущества

✅ Automatic self-aligning – adapt to shaft deflection and reduce friction and wear

✅ High load capacity – four-row roller design, withstands extremely heavy loads

✅ Anti-vibration and shock – suitable for harsh working conditions

✅ Long life – optimize roller contact stress and improve durability

✅ Multiple configurations available – different lubrication, sealing and material solutions

🔩 Structure and features

The four-row spherical roller bearing consists of an outer ring, an inner ring, a cage and rollers. The outer ring adopts a spherical raceway design, and its curvature center coincides with the bearing rotation center, giving the bearing an automatic self-aligning function, which can effectively compensate for the deflection caused by the installation deviation of the shaft and the bearing seat or the bending of the shaft.

📈 Model and specification

The model of the four-row spherical roller bearing usually includes the following elements:

Basic model: such as 22300, 23000 and other series.

Inner ring design identification: for example, C (no rib structure, with stamped cage), CA (with double-sided ribs, with solid cage).

Outer ring feature identification: such as W33 (outer ring with oil groove and three oil holes).

Accuracy and clearance code: P6 (accuracy grade), C3 (radial clearance range).

Temperature resistance grade: S1 (resistant to high temperature of 200°C), S2 (resistant to high temperature of 250°C).

The selection needs to be considered comprehensively in combination with the equipment working conditions and technical parameters.

Распространенные бренды

SKF Spherical Roller Bearing four-row

NSK four-row spherical roller bearing

FAG four-row spherical roller bearing

KOYO four-row spherical roller bearing

NTN four-row spherical roller bearing

TIMKEN four-row spherical roller bearing

NACHI four-row spherical roller bearing

INA four-row spherical roller bearing

🏗️ Application areas

This bearing is widely used in the following scenarios due to its high load-bearing and self-aligning capabilities:

Металлургическое оборудование: heavy equipment such as rolling mills and continuous casting machines.

Горное оборудование: harsh environments such as crushing equipment, screening machines and conveying systems.

Papermaking industry: high-temperature, high-speed and heavy-loaded parts such as drying cylinders and calender rollers.

Textile machinery: fiber processing equipment such as spinning machines and looms.

Power transmission: gearboxes, crane reduction devices, etc.

Fluid machinery: rotating systems such as centrifugal fans and compressors.

Сельскохозяйственная техника: field equipment such as tillers and harvesters.

Marine engineering: axial load support parts such as propeller shafting.

❔ FAQ

Q1: What are the typical application conditions for this type of bearing?

A1: Suitable for occasions with heavy loads, vibrations or poor shaft alignment, such as mining equipment, metallurgical rolling mills, etc.

Q2: What factors should be considered for selection?

A2: Parameters such as load characteristics, speed range, temperature rise limit and installation space need to be comprehensively evaluated.

Q3: What lubrication solutions are recommended?

A3: Grease lubrication or circulating oil lubrication can be selected according to the working conditions, and special lubricants are required for high temperature environments.

Q4: How to improve bearing durability?

A4: The focus includes regular replenishment of lubricants, prevention of contaminants, monitoring of operating loads, and timely replacement of failed parts.

Please see the Сферический роликовый подшипник Catalog for more information!