앵귤러 콘택트 스러스트 볼 베어링

앵귤러 콘택트 스러스트 볼 베어링은 축 방향 및 반경 방향 하중을 모두 견딜 수 있는 고성능 베어링입니다. 최적화된 접촉각 설계를 통해 높은 강성, 낮은 진동, 뛰어난 고속 성능을 제공합니다.

주요 이점:

높은 부하 용량: 축 방향 및 반경 방향 하중을 모두 고려합니다.

뛰어난 고속 성능: 고속 회전 조건에 적합합니다.

높은 정밀도와 강성: 안정적인 축 방향 포지셔닝과 저진동 작동을 보장합니다.

강력한 내구성: 긴 설계 수명으로 다양한 작업 환경에 적응할 수 있습니다.

유연한 설치: 다양한 애플리케이션 시나리오에 적합한 여러 모델을 사용할 수 있습니다.

앵귤러 콘택트 스러스트 볼 베어링 개요

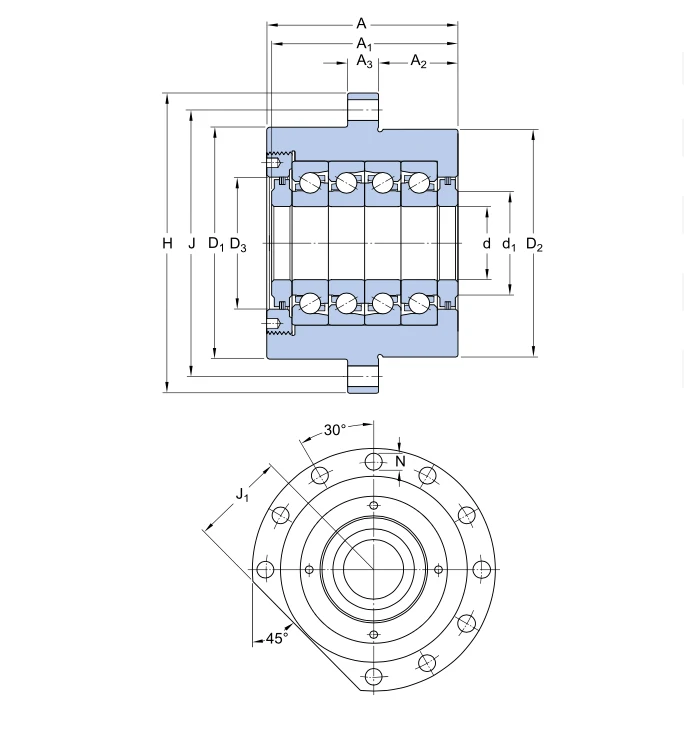

스러스트 앵귤러 콘택트 볼 베어링 은 축 방향 힘과 어느 정도의 반경 방향 힘을 동시에 견딜 수 있도록 특수 설계된 베어링입니다. 강구를 구름 요소로 사용하는 구조로 내륜과 외륜의 특정 접촉각을 통해 높은 강성과 강력한 하중 성능을 달성합니다. 접촉각의 값은 베어링의 하중 지지 한계와 속도 적응성을 직접적으로 결정합니다. 일반적인 각도는 15°, 25°, 40°입니다.

주요 애플리케이션 시나리오

이 유형의 스러스트 볼 베어링 는 많은 산업 분야에서 핵심적인 역할을 하고 있습니다:

정밀 공작 기계: 고속 작동 및 고정밀 요구 사항을 충족하기 위해 스핀들 장치에 사용됩니다.

항공우주: 극한의 부하를 견디고 안정적인 작동을 보장해야 하는 엔진 및 내비게이션 장비에 적합합니다.

차량 제조: 축 방향 지지 특성에 따라 클러치 해제 메커니즘과 조향 장치에서 흔히 볼 수 있습니다.

중장비: 터빈 장비 및 공기 압축기와 같이 축 방향 위치 안정성을 보장해야 하는 장비.

새로운 에너지 분야: 풍력 터빈에서 다방향 동적 부하를 처리하는 데 사용됩니다.

핵심 성능 이점

뛰어난 하중 성능: 축 방향 및 반경 방향 압력을 동시에 효율적으로 견딜 수 있습니다.

고속 적응성: 최적화된 접촉각 설계로 빠른 회전 조건에서도 뛰어난 성능을 발휘합니다.

정밀도와 안정성: 정밀한 축 방향 포지셔닝을 제공하고 작동 진동을 효과적으로 줄입니다.

강력한 내구성: 고품질 소재와 첨단 제조 기술을 사용하여 서비스 수명을 크게 연장합니다.

다양한 구성: 다양한 작업 환경에 적응할 수 있도록 1열, 2열 및 복합 구조를 제공합니다.

일반적인 질문 분석

Q: 이 유형의 베어링과 기존 베어링의 차이점은 무엇인가요?

A: 일반 베어링은 일반적으로 한 방향으로만 하중을 처리할 수 있지만, 각 접촉 추력은 볼 베어링 는 축 방향 및 반경 방향 복합 힘에 동시에 대응할 수 있습니다.

Q: 적합한 접촉각을 선택하는 방법은 무엇인가요?

A: 접촉각이 클수록 축 방향 하중 지지력이 향상되고 고하중 시나리오에 적합하며, 각도가 작을수록 고속 작동 요구 사항에 더 도움이 됩니다.

질문: 일상적인 유지 관리에서 주의해야 할 사항은 무엇인가요?

A: 과부하 작동과 비정상적인 진동을 방지하면서 설치 정확도를 보장하기 위해 윤활 상태를 정기적으로 모니터링해야 합니다.

Q: 극한의 온도 환경에 적합한가요?

A: 가능하지만 고온 및 저온에 강한 특수 재료(예: 세라믹 볼)와 특수 윤활제를 사용해야 합니다.

Q: 베어링의 수명을 연장하는 방법은 무엇인가요?

A: 과학적인 윤활, 표준화된 부하, 청결한 작동 조건을 유지하면 서비스 수명을 효과적으로 연장할 수 있습니다.