When it comes to high-load, low-speed applications in construction machinery, conveyor systems, and heavy-duty transport, Roulements à rouleaux are the unsung heroes of mechanical efficiency. At SKF, we specialize in crafting high-performance bearing solutions that ensure durability, stability, and seamless operation under the most demanding conditions. Our Track Roller Bearings, designed to excel in dynamic environments, form the backbone of undercarriage systems and linear guidance setups worldwide.

Built for Strength, Engineered for Longevity

Le Roulement de galet de roulement is no ordinary component. It is engineered with thick-walled outer rings and deep raceways to accommodate high radial loads and reduce vibration. SKF’s precision manufacturing and advanced surface treatments give these bearings the edge in withstanding extreme shock loads and dirt contamination—critical factors in industries like mining, construction, and manufacturing automation.

Each unit is rigorously tested to ensure it delivers smooth rolling performance over long duty cycles, making it an indispensable part of any heavy-duty undercarriage or material-handling assembly.

Versatility Across Applications

From bulldozers to agricultural sprayers, SKF Track Roller Bearings adapt to a broad range of equipment types. Their primary functions include:

- Guiding loads in cam drives and follower systems

- Supporting continuous movement in track systems and conveyors

- Reducing wear in applications where misalignment or eccentric loading is common

Thanks to SKF’s modular manufacturing process, clients can also order custom sizes and sealing options tailored to their specific engineering demands.

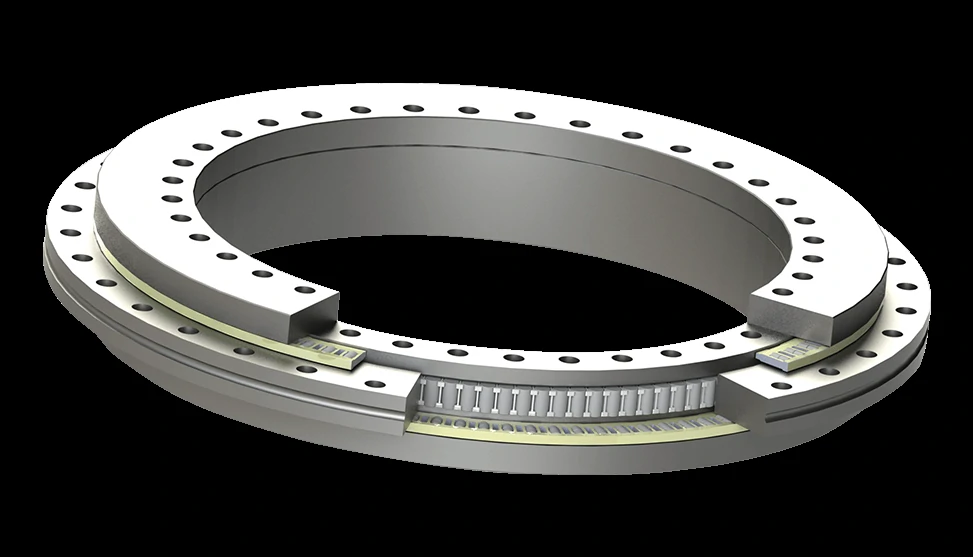

Synergy with Four-Point Contact Ball Bearings

SKF’s product ecosystem includes not only roller-based components but also precision-engineered options like Roulements à billes à contact quadruple. These bearings, often used in rotary tables and automotive gearboxes, can carry axial loads in both directions with minimal friction. In tandem with track roller setups, they offer enhanced control and rigidity—ideal for machinery requiring high precision under variable force conditions.

By integrating these complementary bearing types into a single system, manufacturers can significantly reduce wear, increase operational lifespan, and minimize unplanned downtime.

Seamless Integration with Mounted Deep Groove Ball Bearings

SKF also offers a wide array of Mounted Deep Groove Ball Bearings, which serve as excellent counterparts to roller bearings in many undercarriage designs. Their ease of installation, sealed protection, and superior load handling make them ideal for static and rotating parts exposed to debris and moisture.

When combined with Track Roller Bearings, these mounted solutions create a fully reinforced support structure that withstands both radial and axial forces in rough environments—making them a go-to choice for OEMs and MRO specialists alike.

SKF: Setting the Global Standard

As a global leader in bearing technology, SKF brings over a century of expertise to every component we produce. What sets us apart in the Roulement de galet de roulement space is:

- Advanced heat treatment and sealing technology

- Tight dimensional tolerances for smoother operation

- Comprehensive after-sales engineering support

- Global logistics and fast shipping for replacement units

SKF is not just a supplier—we’re a technical partner committed to extending the life and performance of your machines.