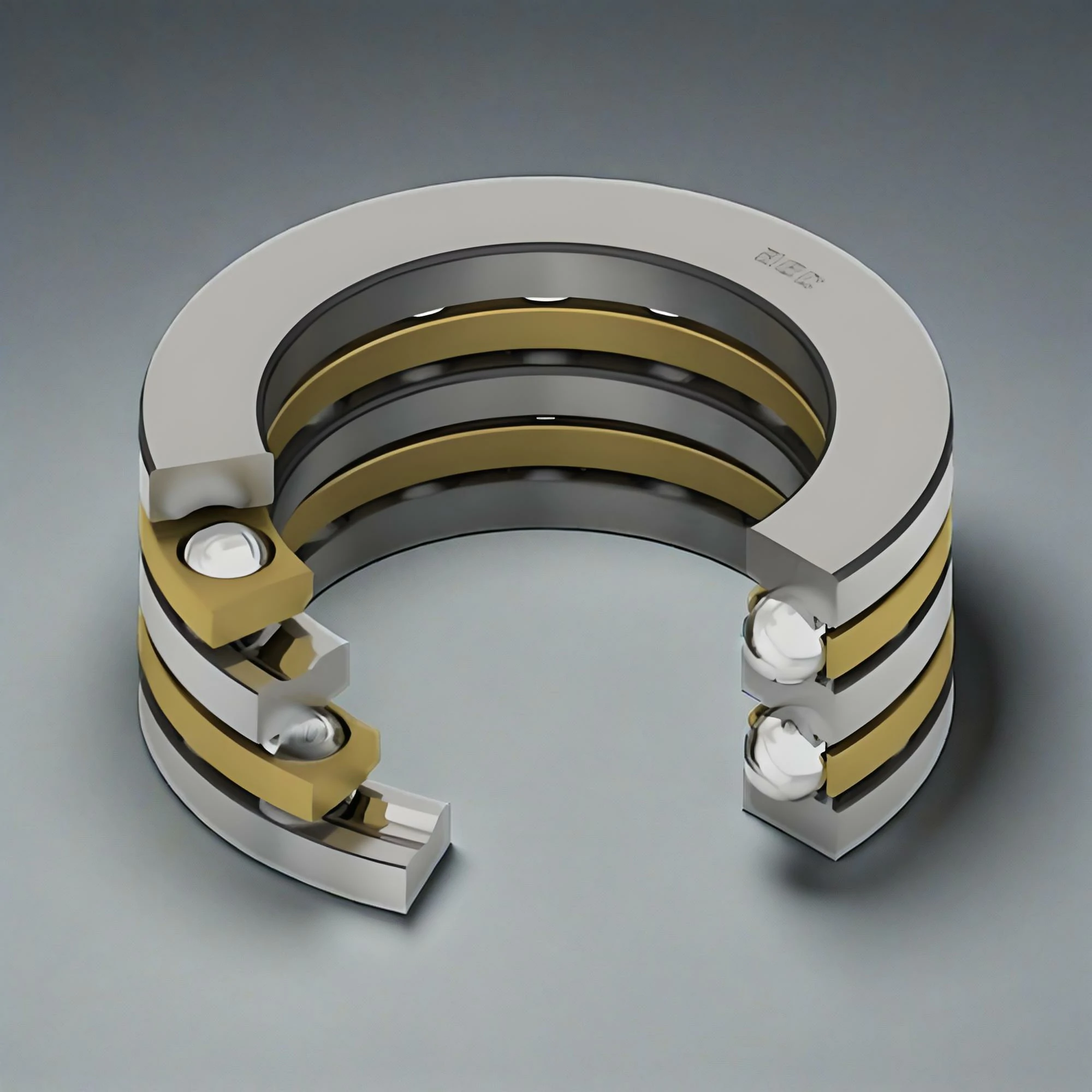

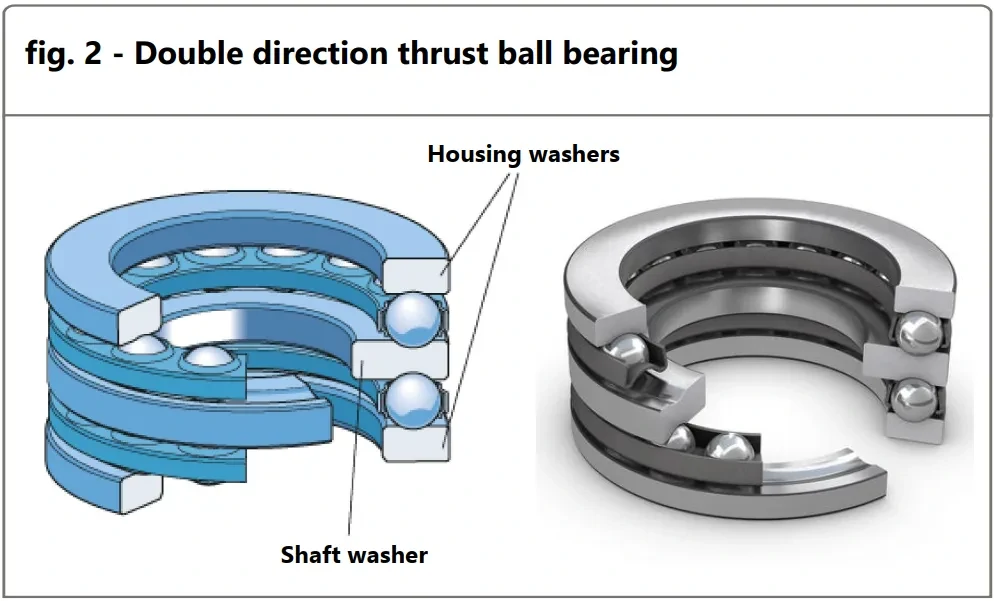

Double-Direction Thrust Ball Bearings

Description: Bidirectional thrust ball bearing is a precision mechanical component that can bear axial loads in both positive and negative directions. Its structure includes two raceway rings, a center shaft ring and a steel ball assembly, which reduces friction through lubricants to ensure smooth operation of the equipment.

Applications:

Machine tools, automotive steering systems, clutches

Steam turbines, wind turbines

Cranes and other engineering machinery

Features:

Bidirectional axial load

Low friction, high efficiency and energy saving

High precision, smooth operation

High temperature resistance, long life

Easy to install and maintain

Overview of Double-Direction Thrust Ball Bearings

Double-direction Roulements à billes de poussée are precision mechanical components designed to withstand bidirectional axial loads. Their structure includes two raceway rings, a center shaft ring, and a steel ball assembly, which are combined with lubricants to reduce friction and ensure smooth operation of the equipment. The bearing is suitable for applications that require bidirectional axial support but do not require radial force.

Main Application Areas

Double-direction thrust Roulements à billes play a key role in multiple industries:

Machine tool processing: ensure high-precision operation, reduce friction, and improve processing quality.

Automotive industry: widely used in steering mechanisms and clutch components.

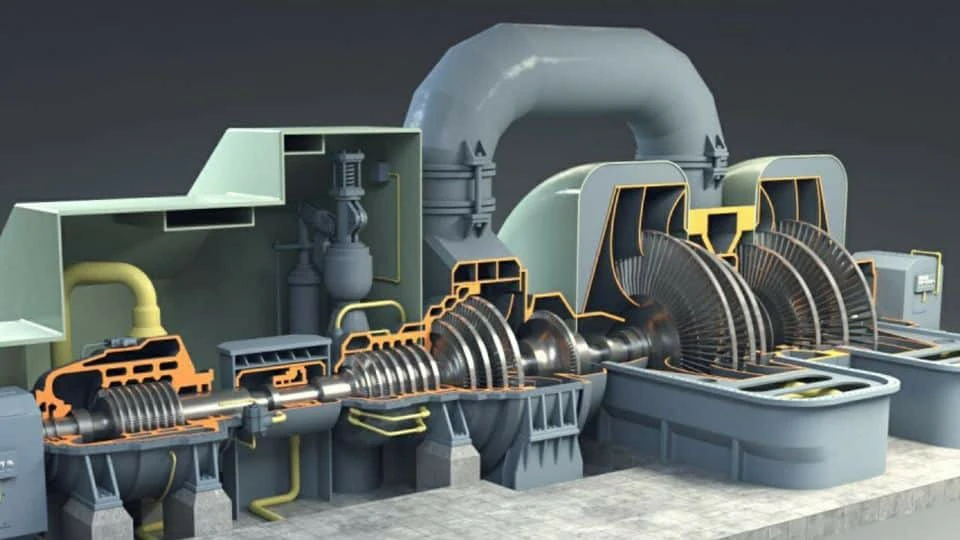

Energy equipment: support steam turbines, water turbines and wind turbines to enhance operational stability.

Engineering machinery: suitable for heavy equipment such as cranes that require bidirectional force.

By adjusting the material and lubrication method, the bearing can also adapt to harsh environments such as high temperature and humidity.

Avantages principaux

Bidirectional load support: can simultaneously cope with axial forces in both positive and negative directions, and adapt to variable working conditions.

High efficiency and energy saving: low friction design reduces energy loss and improves equipment efficiency.

Precision operation: high-precision steel balls and raceways cooperate to ensure smooth operation.

Convenient maintenance: modular structure simplifies installation and maintenance processes.

Long life: high-quality materials and optimized design extend the service life.

FAQ

1. What is the difference between bidirectional and unidirectional thrust ball bearings?

Bidirectional bearings can withstand positive and negative axial forces, while unidirectional bearings only support loads in one direction.

2. What should be paid attention to during installation?

Check whether the clearance between the shaft and the seat ring is appropriate.

Select suitable lubricants and perform regular maintenance.

Avoid violent installation to prevent structural damage.

3. Can it be used in high-temperature environments?

Yes, but high-temperature resistant materials or special lubricants must be used.

4. What are the factors that shorten the life of bearings?

Insufficient lubrication or wrong selection.

Overload operation or improper installation.

External contaminants invade the inside of the bearing.

Conclusion

Double-direction thrust ball bearings have become important components of industrial equipment due to their excellent bidirectional load capacity, high precision and low friction characteristics. Reasonable selection and standardized maintenance can greatly improve equipment reliability and efficiency. In practical applications, the most suitable bearing solution should be selected based on load conditions, working environment and maintenance costs.