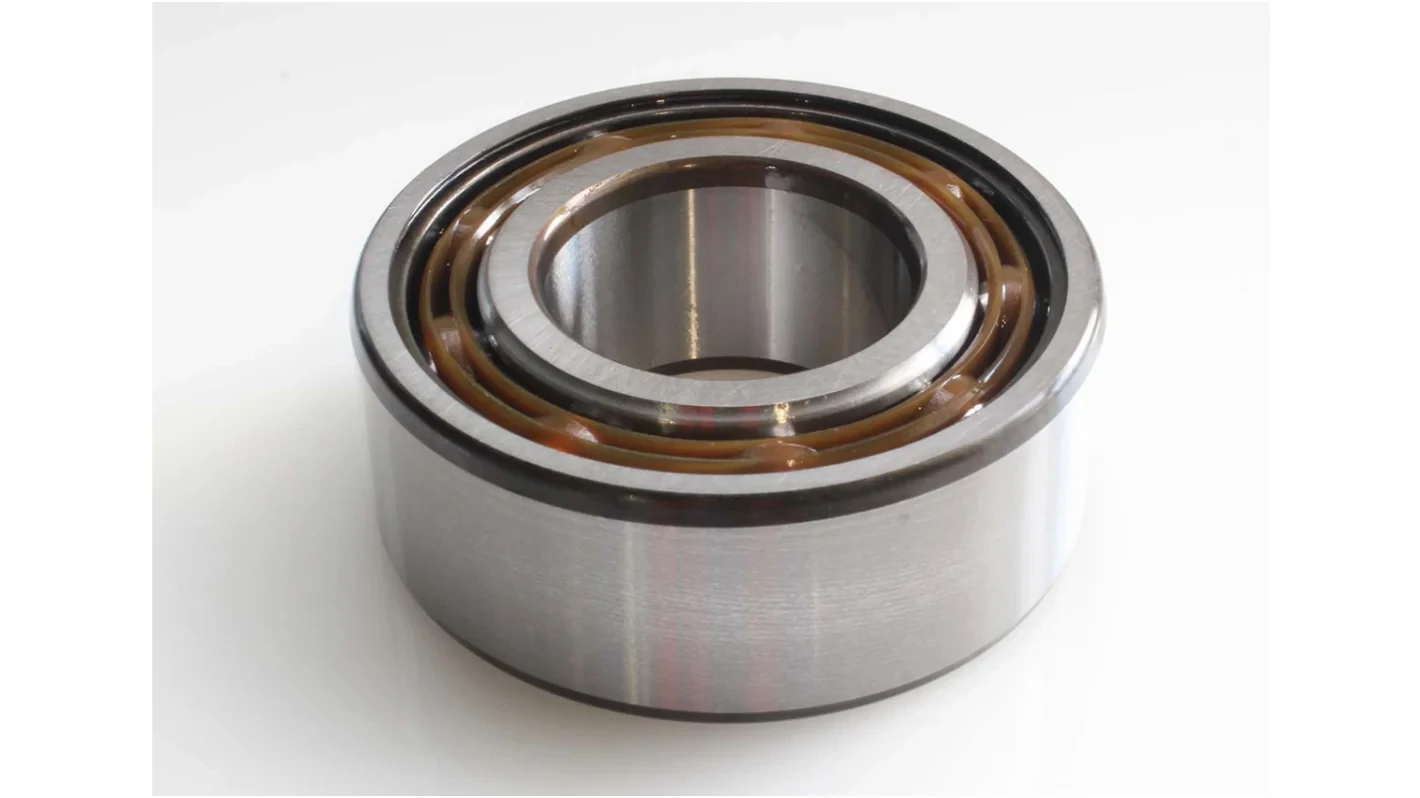

Rodamiento de bolas de contacto angular de doble hilera

Principales aplicaciones

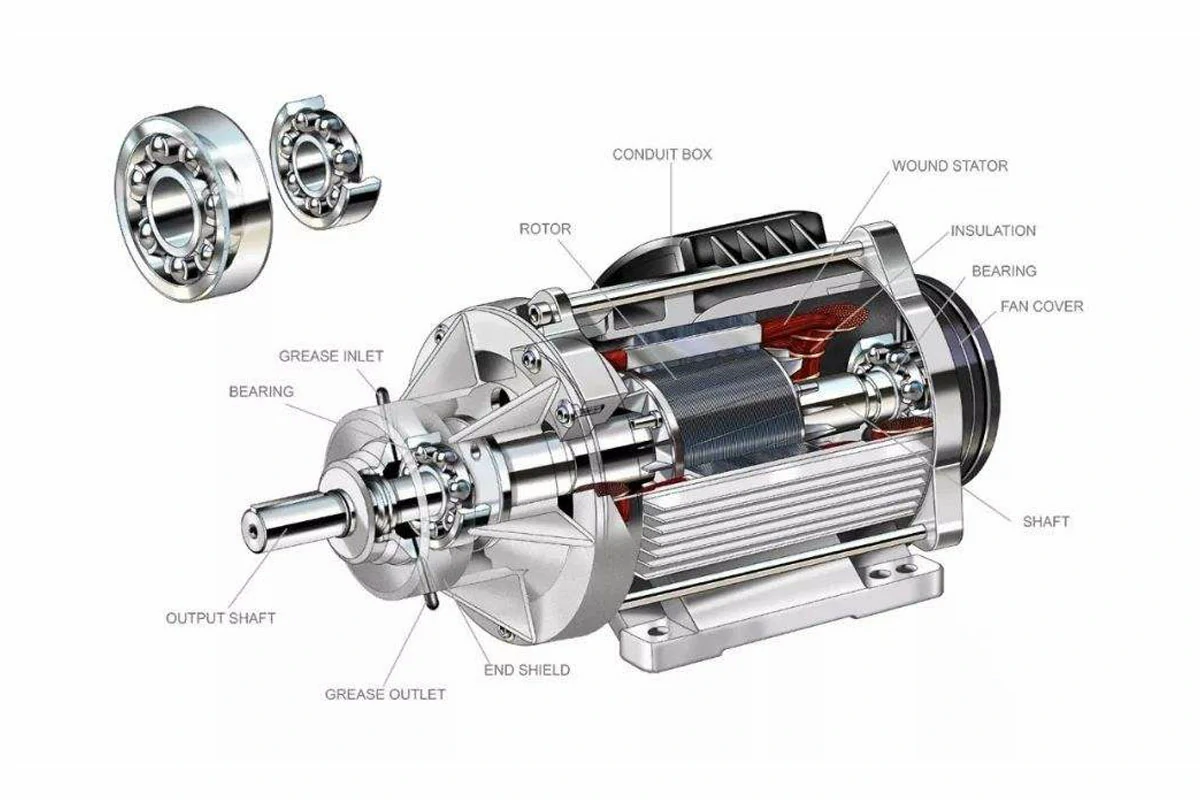

Husillos de máquinas herramienta (centros de mecanizado CNC, rectificadoras)

Sistemas de transmisión para automóviles (motores, cajas de cambios, cubos de rueda)

Equipos de generación de energía eólica (husillos, multiplicadoras)

Robots industriales (rodamientos esféricos, reductores)

Aeroespacial (motores de aviación, trenes de aterrizaje)

Ventajas y características

✅ Alta capacidad de carga: la estructura de doble fila mejora la capacidad de carga radial y axial.

✅ Diseño de ángulo de contacto de alta rigidez optimizado, deformación reducida y precisión mejorada.

✅ Rendimiento de alta velocidad-diseño de baja fricción, adecuado para condiciones de trabajo de alta velocidad.

✅ Larga vida útil: distribución optimizada de la carga, reducción del desgaste y prolongación de la vida útil.

✅ Versatilidad: adecuado para cargas complejas, alta precisión y entornos difíciles.

Tecnología de rodamientos de bolas de contacto angular de doble hilera

A rodamiento de bolas de contacto angular de doble hilera utiliza un diseño con dos filas de bolas de acero dispuestas simétricamente, que puede soportar simultáneamente fuerzas radiales y axiales. Su estructura única le confiere una mayor rigidez y capacidad de carga, y es especialmente adecuado para escenarios industriales con estrictos requisitos de precisión de funcionamiento y rendimiento de soporte de carga. En comparación con los modelos de una hilera, el diseño de doble hilera mejora significativamente el rendimiento general del rodamiento, especialmente en condiciones de funcionamiento a alta velocidad.

Principales ventajas de rendimiento

Capacidad de carga compuesta

El efecto sinérgico de las bolas de acero de doble hilera puede hacer frente simultáneamente a las tensiones radiales y axiales compuestas, y la capacidad de carga aumenta en más de 40% en comparación con los rodamientos de una hilera.

Características de funcionamiento de precisión

El diseño optimizado del ángulo de contacto garantiza un funcionamiento de baja fricción y un excelente control del aumento de temperatura, cumpliendo los requisitos de tolerancia a nivel de micras de los equipos de precisión.

Diseño duradero

La distribución uniforme de la carga reduce el desgaste local y, gracias al acero de alta calidad y a los procesos de tratamiento térmico, la vida útil se prolonga en 30%-50%.

Adaptabilidad versátil

Los tamaños normalizados cubren una amplia gama de condiciones de trabajo y admiten soluciones de estanquidad personalizadas (estanquidad con o sin contacto).

Parámetros técnicos de los modelos típicos

Explicación de los parámetros clave

Relación carga dinámica/estática: refleja el margen de seguridad del rodamiento en estado de rotación y estacionario.

Diseño compacto: pequeño volumen para lograr un alto soporte de carga, optimizar la utilización del espacio del equipo.

Marcas comunes

SKF Rodamiento de bolas de contacto angular de doble hilera

NSK Rodamiento de bolas de contacto angular de doble hilera

FAG Rodamiento a bolas de contacto angular de dos hileras

Rodamiento de bolas de contacto angular INA de dos hileras

KOYO Rodamiento de bolas de contacto angular de doble hilera

TIMKEN Rodamiento de bolas de contacto angular de doble hilera

NACHI Rodamiento de bolas de contacto angular de doble hilera

NTN Rodamiento de bolas de contacto angular de doble hilera

Principales ámbitos de aplicación

Fabricación de equipos de gama alta

El husillo de la máquina herramienta de enlace de cinco ejes adopta rodamientos de precisión de nivel P4 para garantizar una precisión de mecanizado de 0,001 mm.

Vehículos de nueva energía

Los rodamientos del motor de accionamiento deben alcanzar una velocidad superior a 20.000 rpm y soportar la fuerza electromagnética axial del motor.

Equipos de energía limpia

La vida útil del rodamiento del eje principal de la turbina eólica es de 200.000 horas, adaptándose al entorno extremadamente frío de -40℃.

Aeroespacial

Los cojinetes del sistema de transmisión del helicóptero están tratados con una lubricación especial para lograr un funcionamiento estable a 200℃.

Robots inteligentes

El módulo de articulación del robot colaborativo adopta un diseño ultrasilencioso con un ruido de funcionamiento inferior a 45 dB.

Preguntas y respuestas técnicas

P1 ¿Cuáles son las principales ventajas en comparación con los rodamientos de una hilera?

La estructura de doble fila tiene un aumento de la rigidez axial de más de 60%, y la capacidad de carga de empuje bidireccional se ha duplicado, lo que resulta especialmente adecuado para condiciones de trabajo con movimiento axial.

Q2 ¿Temperatura de funcionamiento extrema?

El tipo estándar es adecuado para el rango de -30℃~120℃, y el uso de grasa totalmente sintética puede ampliarse a -50℃~180℃ (como los modelos específicos para el sector aeroespacial).

P3 ¿Factores clave para la selección?

Hay que centrarse en la verificación:

Cálculo de la carga dinámica equivalente (fórmula compuesta Fr+Fa)

Relación entre la velocidad límite y el valor dmN

Método de lubricación y ciclo de relubricación

Q4 ¿Puntos de mantenimiento?

Compruebe el estado de la grasa cada 2000 horas de funcionamiento

Utilice un instrumento de alineación láser para asegurarse de que la excentricidad de la instalación es inferior a 0,02 mm.

El valor de advertencia de control de vibraciones se establece en 4,5 mm/s

Si tiene alguna pregunta, consulte nuestro Rodamientos de bolas de contacto angular Si tiene más preguntas, póngase en contacto con nuestros representantes de ventas.