Mehrreihige Zylinderrollenlager

Wichtigste Anwendungen

✔ Metallurgische Industrie: Walzwerk, Stranggussanlage, Walzenstütze

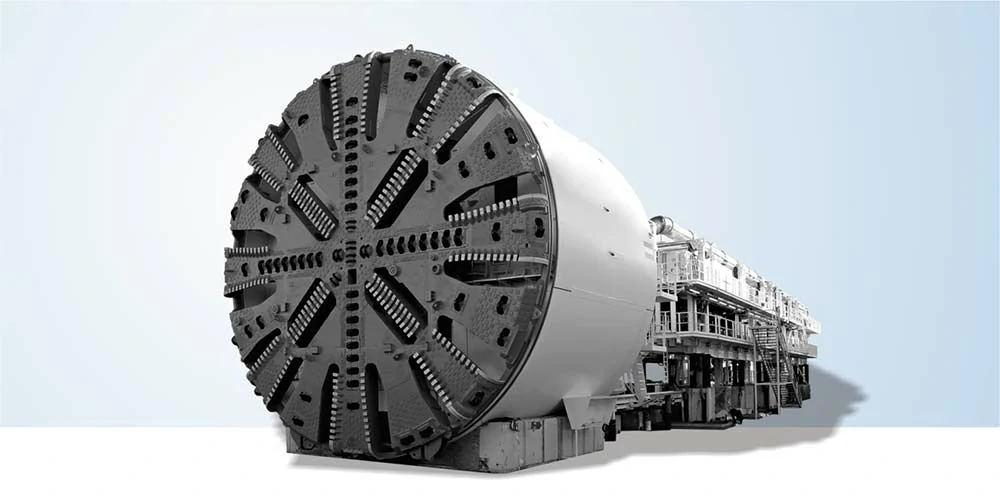

✔ Schwermaschinen: Bergbaumaschinen, Hafenkräne

✔ Präzisionswerkzeugmaschinen: Hochgeschwindigkeitsspindeln, Schleifmaschinen

✔ Energieanlagen: Getriebe für Windkraftanlagen

Vorteile und Merkmale

✅ Ultrahoch belastbar: Mehrreihige Rollen verteilen die Last und halten größeren Radialkräften stand als einreihige Lager

✅ Hohe Steifigkeit: Verringern Sie Verformungen und gewährleisten Sie die Stabilität des Betriebs der Ausrüstung

✅ Lange Lebensdauer: Optimiert die Kraftverteilung und reduziert den lokalen Verschleiß

✅ Anpassungsfähigkeit bei hoher Geschwindigkeit: Präzisionskäfigdesign zur Verringerung der Auswirkungen der Zentrifugalkraft

✅ Mehrere Konfigurationen: zweireihig (Typ NN/NNU), vier Reihen sind optional möglich, um unterschiedliche Lastanforderungen zu erfüllen

🔧 1. Einführung in mehrreihige Zylinderrollenlager

Mehrreihige Zylinderrollenlager haben eine mehrreihige Wälzkörperkonstruktion, die die radiale Tragfähigkeit und die strukturelle Stabilität deutlich erhöht und sich besonders für hohe Belastungen und hohe Betriebsgeschwindigkeiten eignet. Die Hauptkategorien sind wie folgt:

Zweireihige Zylinderrollenlager: zwei parallel angeordnete Rollenreihen, die große Radialkräfte aufnehmen können und häufig in Hochleistungsgetrieben eingesetzt werden.

Vierreihige Zylinderrollenlager: Vierreihige Rollenkombinationen, die speziell für extrem hohe Beanspruchungen entwickelt wurden und typischerweise in Schlüsselteilen wie metallurgischen Walzwerken und Walzanlagen eingesetzt werden.

📊 2. Typische Spezifikationen und technische Parameter

Zweireihige Serie

Typ NNU: Innen- und Außenringe können getrennt werden, sind einfach zu installieren und zu warten und erfüllen die Anforderungen an hohe Präzision.

Typ NN: integrierter Außenring, geeignet für stabile Radiallastszenarien.

Typ NNUP: Mit selbstausrichtenden Scheiben kann die axiale Verschiebung fein abgestimmt werden, um die Systemkompatibilität zu verbessern.

Vierreihige Serie

Konzipiert für ultraschwere Lasten, wie z. B. Walzenzapfenstützen in Walzwerken, können sie schweren Stößen und kontinuierlichen Hochdruckbelastungen standhalten.

🏭 3. Wichtigste industrielle Anwendungen

Metallurgische Ausrüstung: Walzgerüste, Stranggusswalzen usw., um einen kontinuierlichen Betrieb mit hoher Intensität zu gewährleisten.

Präzisionswerkzeugmaschinen: Hochgeschwindigkeitsspindeleinheiten zur Gewährleistung der Rotationsgenauigkeit und Steifigkeit.

Bergbau- und Hebemaschinen: zur Verbesserung der Haltbarkeit der Ausrüstung in rauen Umgebungen.

❓ 4. Wichtige technische Fragen und Antworten

F1: Was sind die Hauptvorteile von mehrreihigen Lagern im Vergleich zu einreihigen Lagern?

A1: Durch die koordinierte Kraft mehrerer Rollenreihen wird die Gleichmäßigkeit der Lastverteilung erheblich verbessert, während die Verformungsbeständigkeit erhöht und die Lebensdauer verlängert wird.

F2: Was ist die zulässige Grenze für vierreihige Lager?

A2: Konzipiert für Mega-Newton-Belastungen wie z. B. metallurgisches Walzen, aber Zwangsschmierung und regelmäßige Wartung sind erforderlich, um den extremen Arbeitsbedingungen gerecht zu werden.

F3: Was ist bei der Auswahl zu beachten?

A3: Es ist notwendig, den dynamischen Belastungsfaktor, die Geschwindigkeitsgrenze und den Einbauraum umfassend zu bewerten und bei Bedarf maßgeschneiderte Lösungen zu wählen.

F4: Bieten wir unseren Kunden gemeinsame Marken an?

A4: Ja, wir bieten SKF-ZylinderrollenlagerKOYO, NSN, FAG, NSK und andere.

✅ 5. Zusammenfassung der Grundwerte

Mehrreihige Zylinderrollenlager sind aufgrund ihres modularen Rollenaufbaus zum bevorzugten Bauteil für industrielle Schwerlastanlagen geworden. Die zweireihigen und vierreihigen Konstruktionen decken Anwendungen mit mittlerer bis hoher bzw. sehr hoher Belastung ab und eignen sich hervorragend für die Bereiche Metallurgie, Werkzeugmaschinen und Schwermaschinen. Bei der Auswahl eines Modells müssen Betriebsparameter und Wartungsbedingungen miteinander kombiniert werden, um die beste Leistung zu erzielen.

Bitte sehen Sie unser Zylinderrollenlager Katalog für weitere Informationen!