Self-Aligning Ball Bearings with Dust Covers (ZZ2Z Type)

Product description:

Double-row ball bearing design, the outer ring adopts spherical raceway structure, which can automatically compensate for the installation deviation between the shaft and the bearing seat. Metal dust covers (ZZ/2Z logo) are equipped on both sides to effectively prevent dust and other pollutants from entering and maintain internal lubrication.

Main applications:

Agricultural machinery (harvester, seeding machine)

Textile equipment

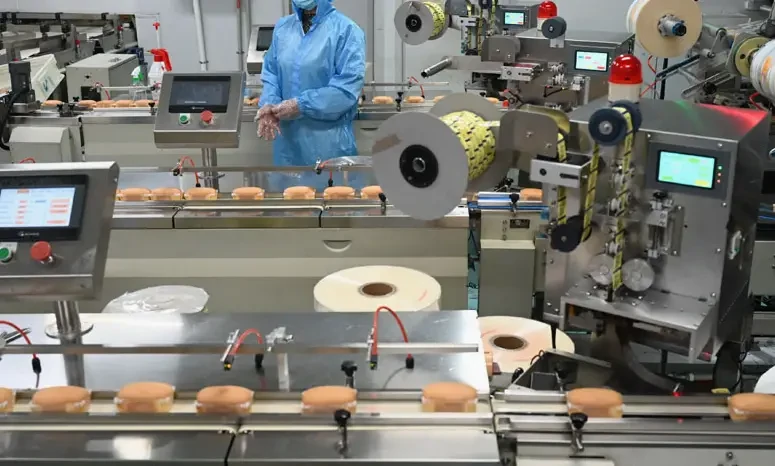

Food processing machinery

Conveying system

Electric motor

Product features:

Automatic self-aligning function (compensation for angle deviation)

Double metal dust cover protection

Low maintenance design

Double-row structure enhances load-bearing capacity

Smooth operation, low noise

Adapt to harsh working environment

Self-Aligning Ball Bearings with Dust Covers (ZZ/2Z Type) – Overview

Self-aligning ball bearings with dust covers (ZZ or 2Z type) feature a double-row ball design with a spherical outer ring raceway, enabling automatic compensation for misalignment between the shaft and housing. These bearings are equipped with metal shields on both sides (ZZ/2Z designation), effectively blocking dust and contaminants while retaining lubrication.

Typical Applications

These bearings are widely used in:

Agricultural Machinery: Ideal for high-dust environments (e.g., seeders, combine harvesters).

Textile Equipment: Provides self-alignment and smooth operation in high-speed, low-vibration settings.

Food Processing: Shields maintain hygiene by minimizing particle ingress.

Conveyor Systems: Commonly used in industrial belt conveyors.

Electric Motors: Suitable for medium-to-low-speed applications with relaxed shaft alignment requirements.

Key Advantages

Self-Aligning Capability: Compensates for mounting errors or shaft deflection.

Dual Metal Shields (ZZ/2Z): Prevent contamination, extending service life.

Reduced Maintenance: Pre-lubricated design minimizes relubrication needs.

High Load Capacity: Double-row construction enhances radial load handling.

Environmental Adaptability: Tolerates minor misalignment and harsh conditions.

Smooth Operation: Low noise and vibration for precision machinery.

FAQ

Q: Are ZZ/2Z bearings waterproof?

A: Shields offer basic dust and light moisture resistance but are not fully waterproof. Avoid submerged use or opt for sealed variants.

Q: Is there a difference between ZZ and 2Z?

A: No—both denote dual metal shields; the labeling varies by manufacturer.

Q: How to select the right model?

A: Consider shaft diameter, load capacity, speed, and operating conditions (e.g., dust, humidity).

Q: Any installation precautions?

A: Ensure clean housing/shaft surfaces, avoid impact mounting, and verify smooth post-installation rotation.

Q: Can shields be removed?

A: No—shields are non-removable. Forcing removal risks damage; use as supplied.

Summary

Combining self-alignment with robust contamination protection, ZZ/2Z bearings excel in long-life, low-maintenance applications. Their sealing and misalignment tolerance make them critical for industrial equipment under demanding conditions.