Cuscinetti a rullini

Caratteristiche principali:

Elevata capacità di carico

Struttura compatta

Leggero

Design a basso attrito

Vantaggi principali

Efficienza di spazio: A parità di carico, il volume è inferiore di 30%~50% rispetto a quello dei cuscinetti a sfera.

Economia: Semplificare la struttura di supporto e ridurre il costo complessivo dell'apparecchiatura.

Adattabilità: Le varianti opzionali, come le guarnizioni, l'assenza di anello esterno o i rulli a rullini a pieno riempimento, consentono di far fronte a condizioni di lavoro complesse.

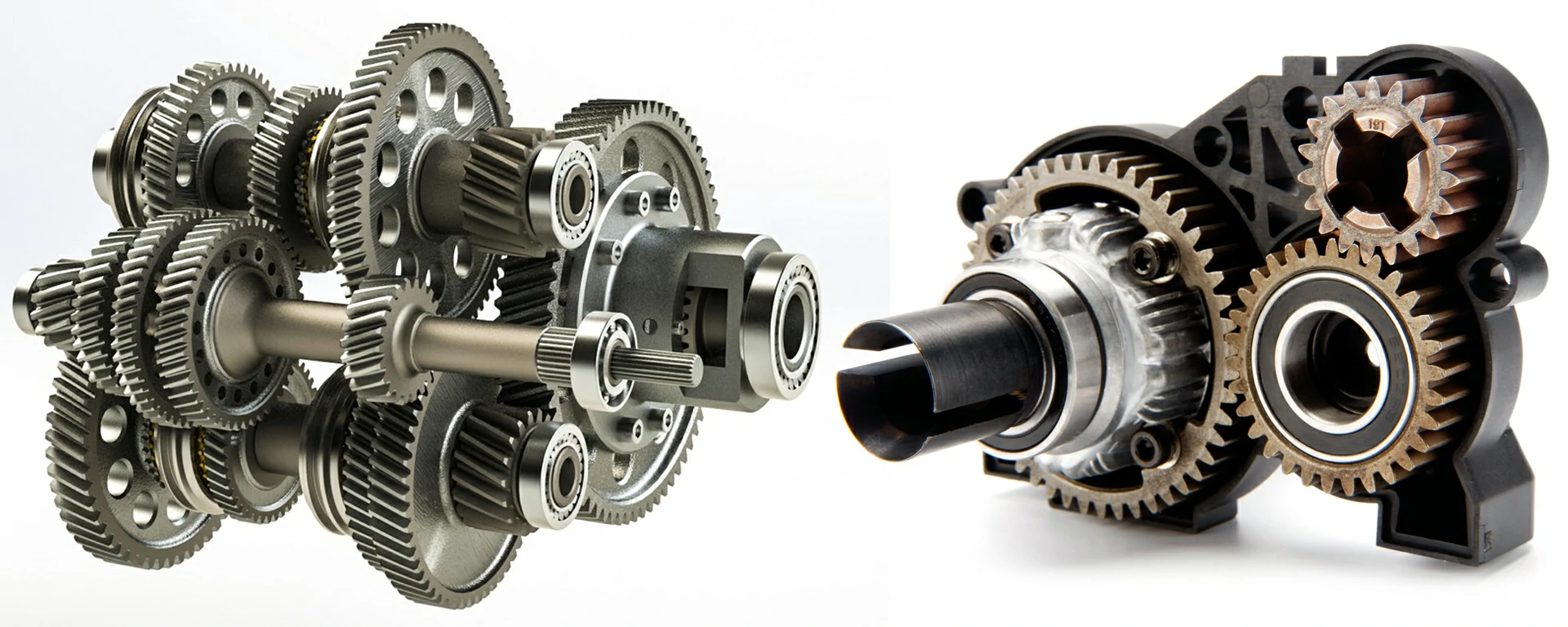

I cuscinetti a rullini sono un tipo di cuscinetto di precisione che utilizza sottili rullini come elementi volventi. Sono una suddivisione dei cuscinetti volventi. I loro vantaggi principali sono la struttura leggera e l'eccellente capacità di carico radiale, particolarmente adatti a condizioni di lavoro con spazio di installazione limitato ma carichi elevati.

Composizione e caratteristiche dei cuscinetti a rullini

I cuscinetti a rullini sono generalmente composti da un anello interno, un anello esterno, un rullino e una gabbia. Il rullo a rullini ha un diametro più piccolo e un rapporto d'aspetto significativamente più alto rispetto ai rulli ordinari o alle sfere d'acciaio, in modo da fornire un supporto di carico più forte nello stesso spazio e ridurre il peso complessivo.

Parametri tecnici di riferimento del modello tipico

Marchi comuni:

Cuscinetti a rullini SKF

Cuscinetti a rullini NSK

Cuscinetti a rullini KOYO

Cuscinetti a rullini FAG

Cuscinetti a rullini INA

Cuscinetti a rullini TIMKEN

Cuscinetti a rullini NACHI

Tipi e applicazioni dei cuscinetti a rullini

1. Cuscinetti a rullini a una corona

Scenari applicabili: cambi automobilistici, alberi di trasmissione di motocicli e altre parti che richiedono velocità e carichi elevati.

Vantaggi: Struttura semplificata, risposta dinamica rapida, adatta a condizioni di avvio e arresto frequenti.

2. Cuscinetti a rullini a due corone

Scenari applicabili: apparecchiature ad alto carico, come le piattaforme girevoli dei macchinari ingegneristici e i sistemi di sospensione dei veicoli pesanti.

Vantaggi: Il design a due corone di rullini migliora notevolmente la capacità dei cuscinetti radiali e ha una migliore resistenza agli urti.

3. Cuscinetti a rullini con anello esterno integrato

Scenari di applicazione: riduttori industriali, guide di macchine utensili e altre occasioni in cui è necessario aumentare la rigidità.

Vantaggi: L'anello esterno rafforza la struttura complessiva ed è adatto ad ambienti di carico complessi.

4. Cuscinetti a rullini senza anelli esterni

Scenari applicabili: motori di aerei, strumenti di precisione e altri settori che richiedono una rigorosa precisione di installazione.

Vantaggi: Utilizzare direttamente le parti meccaniche come piste di scorrimento per risparmiare al massimo lo spazio.

Domande frequenti

Q1: Qual è la competitività di base dei cuscinetti a rullini?

R: Può supportare carichi elevati in uno spazio limitato e presenta caratteristiche di leggerezza e basso attrito, superiori alla capacità di carico radiale dei cuscinetti a sfera tradizionali.

Q2: Come distinguere i cuscinetti a rullini dai cuscinetti a rulli cilindrici?

R: Il rapporto d'aspetto dei corpi volventi dei cuscinetti a rullini è maggiore ed è adatto a spazi ridotti; i cuscinetti a rulli cilindrici sono più adatti all'equilibrio tra carichi e velocità medie.

D3: Quali sono le misure chiave per migliorare la durata dei cuscinetti a rullini?

R: Sostituire regolarmente i lubrificanti, controllare la temperatura di esercizio, evitare il sovraccarico e garantire la coassialità dell'albero e della sede del cuscinetto durante l'installazione.

D4: Quali sono gli effetti dei fattori ambientali sulla performance?

R: Le temperature estreme o i fluidi corrosivi accelerano i guasti della lubrificazione e sono necessari materiali speciali (come l'acciaio inossidabile) o design di tenuta per far fronte alle condizioni difficili.

Q5: Il rumore di funzionamento è elevato?

R: A causa delle caratteristiche del contatto di linea, il rumore è leggermente superiore a quello dei cuscinetti a sfera a contatto puntiforme. I rumori anomali sono per lo più causati da una scarsa lubrificazione o dall'usura dei componenti, che devono essere controllati in tempo.

Conclusione

I cuscinetti a rullini sono la scelta ideale per le condizioni di lavoro in cui lo spazio è limitato, grazie alla distribuzione del carico ad alta densità e al design compatto. Una selezione ragionevole (fila singola/doppia, con anello esterno/senza anello esterno) e una manutenzione standardizzata possono ottimizzare in modo significativo le prestazioni e la durata, soddisfacendo le diverse esigenze, dai macchinari civili alle apparecchiature industriali di fascia alta.

Si prega di consultare il nostro Cuscinetti a rulli Catalogo per altri prodotti!