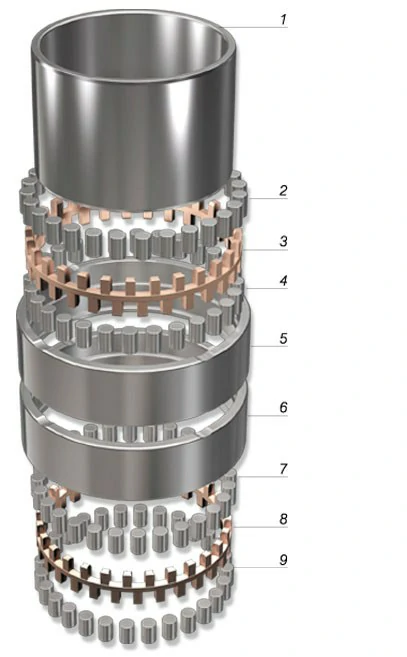

four-row spherical roller bearing

Applicazioni principali

Heavy industry: rolling mills, continuous casting machines

Mining machinery: crushers, vibrating screens

Papermaking equipment: drying cylinders, calendering rollers

Textile machinery: spinning machines, looms

Reducers and gearboxes: high-load transmission systems

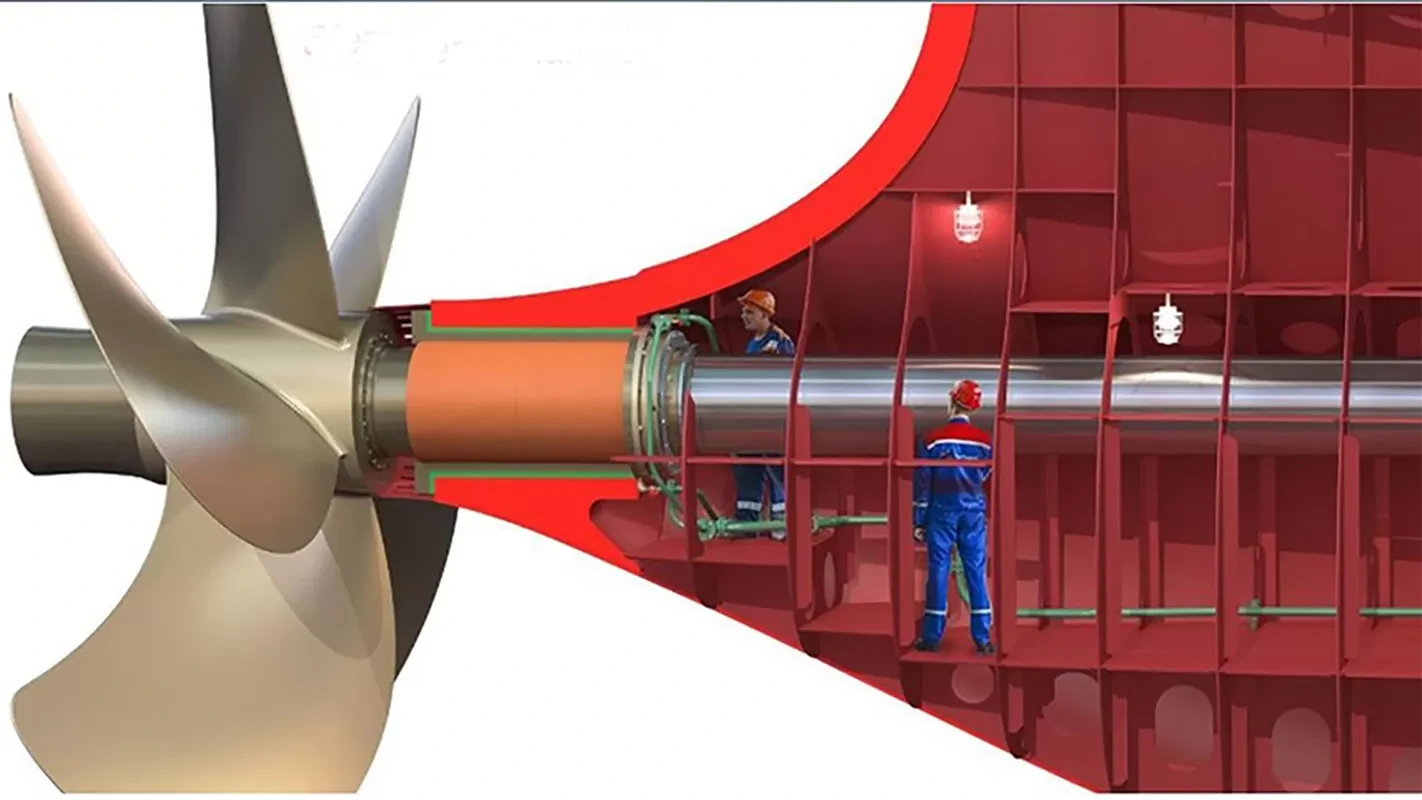

Ship propulsion: propeller shaft support

Vantaggi principali

✅ Automatic self-aligning – adapt to shaft deflection and reduce friction and wear

✅ High load capacity – four-row roller design, withstands extremely heavy loads

✅ Anti-vibration and shock – suitable for harsh working conditions

✅ Long life – optimize roller contact stress and improve durability

✅ Multiple configurations available – different lubrication, sealing and material solutions

🔩 Structure and features

The four-row spherical roller bearing consists of an outer ring, an inner ring, a cage and rollers. The outer ring adopts a spherical raceway design, and its curvature center coincides with the bearing rotation center, giving the bearing an automatic self-aligning function, which can effectively compensate for the deflection caused by the installation deviation of the shaft and the bearing seat or the bending of the shaft.

📈 Model and specification

The model of the four-row spherical roller bearing usually includes the following elements:

Basic model: such as 22300, 23000 and other series.

Inner ring design identification: for example, C (no rib structure, with stamped cage), CA (with double-sided ribs, with solid cage).

Outer ring feature identification: such as W33 (outer ring with oil groove and three oil holes).

Accuracy and clearance code: P6 (accuracy grade), C3 (radial clearance range).

Temperature resistance grade: S1 (resistant to high temperature of 200°C), S2 (resistant to high temperature of 250°C).

The selection needs to be considered comprehensively in combination with the equipment working conditions and technical parameters.

Marchi comuni

SKF Spherical Roller Bearing four-row

NSK four-row spherical roller bearing

FAG four-row spherical roller bearing

KOYO four-row spherical roller bearing

NTN four-row spherical roller bearing

TIMKEN four-row spherical roller bearing

NACHI four-row spherical roller bearing

INA four-row spherical roller bearing

🏗️ Application areas

This bearing is widely used in the following scenarios due to its high load-bearing and self-aligning capabilities:

Metallurgical equipment: heavy equipment such as rolling mills and continuous casting machines.

Mining machinery: harsh environments such as crushing equipment, screening machines and conveying systems.

Papermaking industry: high-temperature, high-speed and heavy-loaded parts such as drying cylinders and calender rollers.

Textile machinery: fiber processing equipment such as spinning machines and looms.

Power transmission: gearboxes, crane reduction devices, etc.

Fluid machinery: rotating systems such as centrifugal fans and compressors.

Agricultural machinery: field equipment such as tillers and harvesters.

Marine engineering: parti di supporto del carico assiale, come l'albero dell'elica.

❔ FAQ

Q1: Quali sono le condizioni di applicazione tipiche di questo tipo di cuscinetti?

A1: Adatto per occasioni con carichi pesanti, vibrazioni o cattivo allineamento dell'albero, come attrezzature minerarie, laminatoi metallurgici, ecc.

D2: Quali sono i fattori da considerare per la selezione?

A2: È necessario valutare in modo approfondito parametri quali le caratteristiche di carico, il campo di velocità, il limite di aumento della temperatura e lo spazio di installazione.

D3: Quali soluzioni di lubrificazione sono consigliate?

A3: La lubrificazione a grasso o a olio circolante può essere scelta in base alle condizioni di lavoro; per gli ambienti ad alta temperatura sono necessari lubrificanti speciali.

D4: Come migliorare la durata dei cuscinetti?

A4: L'attenzione comprende il rifornimento regolare di lubrificanti, la prevenzione dei contaminanti, il monitoraggio dei carichi operativi e la sostituzione tempestiva delle parti guaste.

Si prega di consultare il Cuscinetto a rulli sferici Catalogo per maggiori informazioni!