In industries where machinery is pushed to its limits, only the most robust bearing solutions can endure. The Cuscinetti a rulli sferici reggispinta, developed and perfected by SKF, is built for extreme axial loads and high-impact environments. Whether in mining, marine propulsion, or large gear drives, these bearings offer unmatched stability, load distribution, and shock resistance.

SKF’s legacy in high-precision engineering positions it as a trusted global leader in supplying bearings that go beyond expectations. The Thrust Spherical Roller Bearing is one such innovation—a vital component when axial loads and misalignment converge in harsh operating conditions.

Designed for High Axial Loads and Misalignment

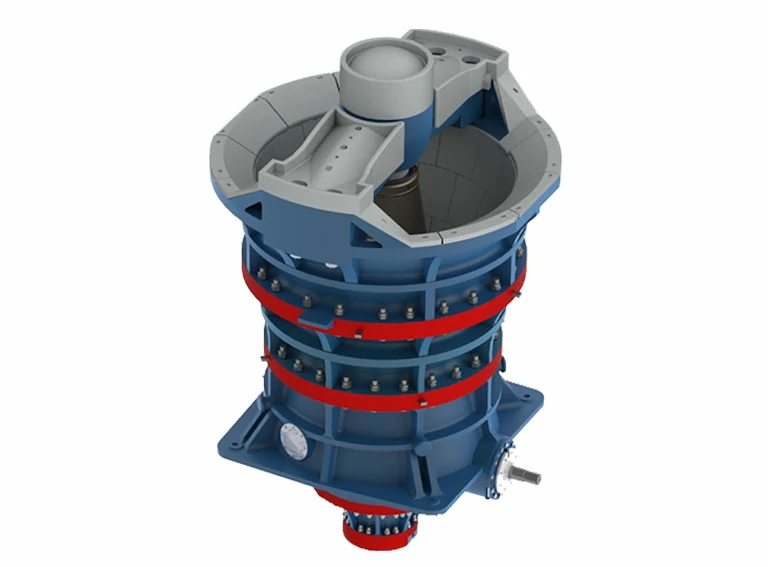

Thrust Spherical Roller Bearings are designed to take up axial loads in a single direction and at the same time they are allowed to have shaft misalignment. This fact is what makes the bearings suitable for the following:

- Vertical shaft applications such as hydro turbines

- Industrial gearboxes

- Heavy-duty lifting and hoisting equipment

- Crushers and conveyors in mining

SKF’s design comprises of rollers that are not the same size and internal geometry that is more efficient, resulting in reduced friction and heat generation. In practice, this solicits the products to exhibit significantly longer service intervals even when working under much higher or less than adequate lubrication levels.

Tapered Bore Self-Aligning Ball Bearings: A Perfect Companion

When it comes to versatile support systems, SKF often combines Thrust Spherical Roller Bearings with Cuscinetti a sfere autoallineanti a foro conico. The latter provides excellent support in radial and moderate axial load applications and compensates for shaft deflection and mounting errors.

Used together, these two bearing types create a complete system capable of handling misaligned shafts and varied directional loads—a critical asset in paper mills, processing plants, and vertical pump assemblies.

Advanced Lubrication and Heat Management

SKF integrates heat treatment technology and specialized channels for the distribution of lubricants into its Thrust Spherical Roller Bearings to make them more thermally stable and require less frequent maintenance. This enhancement especially has an enormous value in the case of so-called running processes like metallurgical casting or cement manufacture because the bearing overheating amidst l

Actions taken to cool and lube the machinery while it’s still running can lead to serious machines failure and, hence, severe stoppages. All the particles that have been ground away and are passing through the seal, invariably leads to premature bearing failure and frequent replacement times occur. Keeping this in mind, it is always important to provide the worn-to-damage particles and through such a case, it is highly possible o.

Moreover, there are durable machined brass or steel cages that provide a smooth channel for the rollers, and their limiting speeds are higher compared to the traditional cast cages.

When Thrust Hydrostatic Bearings Aren’t Enough

In ultra-high-load environments, Thrust hydrostatic bearings—which use fluid film lubrication—are sometimes used. However, these systems require constant power supply and are highly sensitive to debris or oil contamination.

SKF’s Thrust Spherical Roller Bearings, in contrast, offer a more resilient mechanical solution without relying on pressurized fluid systems. They deliver performance close to hydrostatic bearings but with far lower complexity and operating cost. This makes them ideal for applications that demand simplicity, reliability, and maintenance accessibility—especially in off-grid or remote installations.

Global Reach, Local Expertise

SKF supports industrial clients worldwide through a strong distribution network and experienced engineering teams. Whether you need custom bearing configurations, technical consulting, or fast-track delivery, SKF provides:

- Regional warehouses with global shipping coverage

- CAD design support for integration into custom machinery

- Bearing condition monitoring and predictive maintenance tools

- Technical documentation in over 20 languages

As your long-term bearing partner, SKF ensures the Cuscinetti a rulli sferici reggispinta performs at its peak, no matter where it’s installed.