Abstract

The selection and implementation of rolling element bearings represent a foundational aspect of modern mechanical engineering, directly influencing the reliability and efficiency of machinery across diverse industries. This guide examines the products of KOYO, a brand under the JTEKT Corporation, renowned for its contributions to bearing technology. It presents a systematic, seven-step methodology for engineers, procurement managers, and technicians, particularly those operating in the demanding economic and environmental contexts of South America, Russia, Southeast Asia, the Middle East, and South Africa. The process detailed herein moves from a foundational comprehension of application-specific demands—such as load, speed, and environment—to a nuanced navigation of the KOYO product portfolio. The discourse extends to material science, lubrication strategies, service life prediction, and maintenance protocols. By addressing the pervasive issue of counterfeit components, the guide culminates in strategies for product authentication and supplier verification, aiming to mitigate the substantial economic and operational risks associated with premature bearing failure and unscheduled downtime.

Key Takeaways

- Analyze your application's load, speed, and environment before selecting a bearing.

- Match your specific need to a product in the KOYO bearings portfolio, from ball to roller types.

- Verify material specifications and precision classes to ensure performance and longevity.

- Implement a correct lubrication and sealing strategy to protect against contamination.

- Use proper mounting and maintenance techniques to prevent premature failure.

- Calculate bearing life to forecast maintenance and manage operational budgets effectively.

- Always authenticate products and vet suppliers to avoid counterfeit-related damages.

Table of Contents

- Step 1: Comprehending Your Application's Demands

- Step 2: Navigating the KOYO Bearing Portfolio

- Step 3: Scrutinizing Material and Quality Specifications

- Step 4: Mastering Lubrication and Sealing Strategies

- Step 5: Calculating and Predicting Bearing Service Life

- Step 6: Ensuring Proper Installation and Maintenance Practices

- Step 7: Authenticating Your KOYO Bearings and Choosing a Reliable Supplier

- Frequently Asked Questions (FAQ)

- Conclusion

- References

Step 1: Comprehending Your Application's Demands

The endeavor of selecting a bearing begins not with a catalog, but with a deep and thoughtful inquiry into the world the bearing will inhabit. A bearing is not an isolated component; it is a participant in a dynamic mechanical system. Its success or failure is contingent upon how well its design corresponds to the forces and conditions it will experience. To treat this initial step with anything less than meticulous care is to build a machine on a foundation of uncertainty. Imagine, for a moment, constructing a building. Would you select the foundational materials without first understanding the soil composition, the seismic activity of the region, or the total weight the structure must support? The same principle applies with resounding force to the world of rotating machinery. The bearing is the foundation upon which reliability is built.

For professionals in regions like the arid plains of the Middle East, the humid agricultural zones of Southeast Asia, or the resource-extraction sites in South Africa and Russia, this initial analysis carries even greater weight. Environmental challenges are not abstract concepts but daily operational realities. Dust, moisture, extreme temperature fluctuations, and corrosive agents are active antagonists to machine longevity. A failure to account for these factors at the outset will inevitably lead to operational disruptions that are far more costly than the initial price difference between an adequate bearing and an ideal one.

Analyzing Load Characteristics: Radial, Axial, and Combined Forces

At the heart of any bearing's function is the management of load. A load, in this context, is simply a force that the bearing must support and transmit. These forces, however, are not monolithic; they possess direction and character. The primary distinction we must make is between radial and axial loads.

Think of a car wheel. The weight of the car presses directly downwards on the axle. The bearing supporting that axle experiences this force perpendicular to the axis of rotation. This is a radial load. It acts from the "radius" of the shaft outwards. Now, consider the same car making a sharp turn. As the car corners, a force pushes the wheel sideways, along the line of the axle itself. This is an axial load or thrust load. It acts parallel to the axis of rotation.

Very few applications present a purely radial or purely axial load. Most machinery, from industrial gearboxes to conveyor belt pulleys, subjects its bearings to a combined load—a mixture of both radial and axial forces. The critical task for the engineer or technician is to quantify these loads. How much force is radial? How much is axial? The ratio between them is a primary determinant in selecting the right type of KOYO bearing. A Deep Groove Ball Bearing might handle light to moderate axial loads in addition to its primary radial capacity. A Cylindrical Roller Bearing, by contrast, is a master of heavy radial loads but typically possesses very little axial load capacity on its own. For heavy combined loads, a Tapered Roller Bearing or a Spherical Roller Bearing becomes the logical candidate.

The nature of the load is also a consideration. Is the load constant and steady, like in a ventilation fan? Or is it a shock load, characterized by sudden, high-magnitude impacts, as one might find in a rock crusher or a stamping press? Shock loads demand bearings with greater toughness and often a higher static load capacity to resist permanent deformation (brinelling) of the raceways.

Evaluating Speed and Rotational Requirements

Speed is the second pillar of application analysis. The rotational speed of the shaft, typically measured in revolutions per minute (RPM), dictates a bearing's thermal behavior and its lubrication requirements. As a bearing rotates, a small amount of friction is generated between the rolling elements, the raceways, and the cage. This friction produces heat. At low speeds, this heat is negligible and dissipates easily. As speeds increase, however, heat generation can become a significant factor.

A useful concept here is the "speed rating" or "limiting speed" provided in bearing catalogs. This value is not an absolute maximum but a thermal reference point. Exceeding it without special considerations—such as enhanced lubrication methods (oil circulation instead of grease), higher precision classes, or special cage materials—risks thermal runaway. In this state, the heat generated exceeds the heat dissipated, causing the bearing's temperature to rise uncontrollably. This leads to lubricant degradation, loss of internal clearance, and swift, catastrophic failure.

For very high-speed applications, such as machine tool spindles or turbochargers, the design of the bearing becomes paramount. Here, the mass of the rolling elements themselves generates significant centrifugal forces, which can alter the contact mechanics within the bearing. This is why high-speed applications often favor bearings with smaller, lighter rolling elements, such as those found in Angular Contact Ball Bearings, or even ceramic (silicon nitride) balls, which are substantially less dense than steel. The choice of a KOYO bearing for a high-speed grinder will be fundamentally different from the choice for a slow-moving agricultural conveyor.

Assessing Environmental Conditions: Temperature, Contamination, and Vibration

The final piece of this initial inquiry is the operational environment. A bearing that performs flawlessly in a clean, climate-controlled facility may fail in a matter of hours in a different setting.

Temperature is a primary concern. Ambient temperatures, as well as heat conducted from the machinery itself, affect the bearing in multiple ways. High temperatures degrade lubricants, reducing their viscosity and protective film-forming ability. They also cause thermal expansion of the bearing components and the surrounding housing and shaft. This expansion can reduce or eliminate the bearing's internal clearance, leading to excessive preload and premature failure. In the extreme heat of a steel mill or a desert-based pumping station, specialized KOYO bearings with larger internal clearances (like C4 or C5) and high-temperature greases are not optional luxuries; they are necessities. Conversely, in the cryogenic temperatures of liquefied natural gas processing or the harsh winters of Siberia, steel can become brittle. Special materials and lubricants are required to prevent fracture.

Contamination is the bearing's most persistent enemy. Dust, dirt, sand, water, and chemical process fluids are all abrasive or corrosive agents. A single hard particle entering a bearing can be repeatedly rolled over by the elements, denting the raceways and creating stress risers that become the nucleation points for fatigue failure. Water can lead to corrosion and hydrogen embrittlement of the steel. This is why the selection of seals or shields is not a minor detail. A non-contact metal shield (often designated ZZ by KOYO) is suitable for excluding larger particles in a relatively clean environment. In a dirty or wet environment, such as a cement plant or a food processing line with frequent washdowns, a contact rubber seal (designated 2RS) that provides a positive barrier against ingress is indispensable.

Vibration adds another layer of complexity. All machines vibrate to some extent, but excessive vibration can be detrimental. It can disrupt the lubricant film, leading to metal-to-metal contact, or it can cause a type of wear known as false brinelling in stationary bearings subjected to external vibration. The source and frequency of the vibration must be understood. Is it a high-frequency vibration from an imbalanced motor, or a low-frequency, high-amplitude shock from a reciprocating machine? The bearing's internal geometry and cage design can influence its ability to withstand these dynamic conditions. A robust, roller-guided brass cage, for instance, often performs better under high vibration than a standard stamped steel cage.

| Bearing Type | Typical Radial Load Capacity | Typical Axial Load Capacity | Speed Capability | Tolerance to Misalignment |

|---|---|---|---|---|

| Deep Groove Ball Bearing | Good | Moderate | Very High | Low |

| Cylindrical Roller Bearing | Excellent | Very Low (or Moderate with special ribs) | High | Very Low |

| Tapered Roller Bearing | Very Good | Very Good (in one direction) | Moderate | Low |

| Spherical Roller Bearing | Excellent | Good | Moderate | Very High |

| Angular Contact Ball Bearing | Good | Excellent (in one direction) | Very High | Very Low |

| Plain Bearing | Varies (Excellent) | Varies (Excellent) | Low to Moderate | High |

This table serves as a preliminary guide. The true art of engineering lies in understanding the nuances behind these general characteristics and applying them to the specific, quantified demands of the application at hand. Only by completing this first step with diligence can one proceed to the next phase with confidence.

Step 2: Navigating the KOYO Bearing Portfolio

With a clear and detailed portrait of the application's demands—its loads, speeds, and environmental context—one can now turn to the KOYO bearing catalog with purpose. This is no longer a search; it is a matching process. The KOYO portfolio, a result of decades of Japanese engineering refinement under the JTEKT Corporation, offers a vast lexicon of solutions. To navigate it effectively is to understand the language of its different "families" of bearings, each with its own syntax of design and purpose. Approaching this vast offering without the prerequisite knowledge from Step 1 is akin to entering a library with a million books without knowing the subject you wish to study. You will be lost in a sea of part numbers. But with your application requirements as your guide, the catalog transforms into a map.

This step involves moving from the general to the specific. If your analysis revealed a need for high radial load capacity with some tolerance for misalignment, your focus immediately narrows to Spherical Roller Bearings. If the dominant requirement is very high speed with precision axial positioning, you are drawn to the section on Angular Contact Ball Bearings. Let us explore the primary categories within the KOYO family to understand their inherent capabilities.

Deep Groove Ball Bearings: The Versatile Workhorse

The Deep Groove Ball Bearing is arguably the most common and recognizable type of rolling bearing in the world. Its design is one of elegant simplicity: a set of spherical balls running in deep, circular grooves in both the inner and outer rings. This geometry is its greatest strength. The "deep groove" allows it to support not only significant radial loads but also axial loads in both directions, making it exceptionally versatile.

Think of it as the all-season tire of the bearing world. It performs well in a huge range of conditions, which is why you will find KOYO Deep Groove Ball Bearings in everything from small electric motors and household appliances to automotive transmissions and industrial gearboxes. They are capable of very high speeds, generate low friction, and are available in a vast array of sizes, from miniature bearings a few millimeters in diameter to large units for heavy machinery.

Their versatility is also expressed in the options available. They can be open (for oil or grease lubrication within a sealed housing), fitted with metal shields (ZZ) to keep out large contaminants without adding friction, or equipped with contact seals (2RS, LLU) for robust protection in dirty or wet environments. A reputable bearing manufacturer will offer a wide range of these options. The ubiquity of this Ball Bearing type, however, should not lead to complacency. While versatile, it is not a universal solution. Its misalignment tolerance is very low, and for applications with very heavy radial or axial loads, other bearing types offer superior performance and longevity.

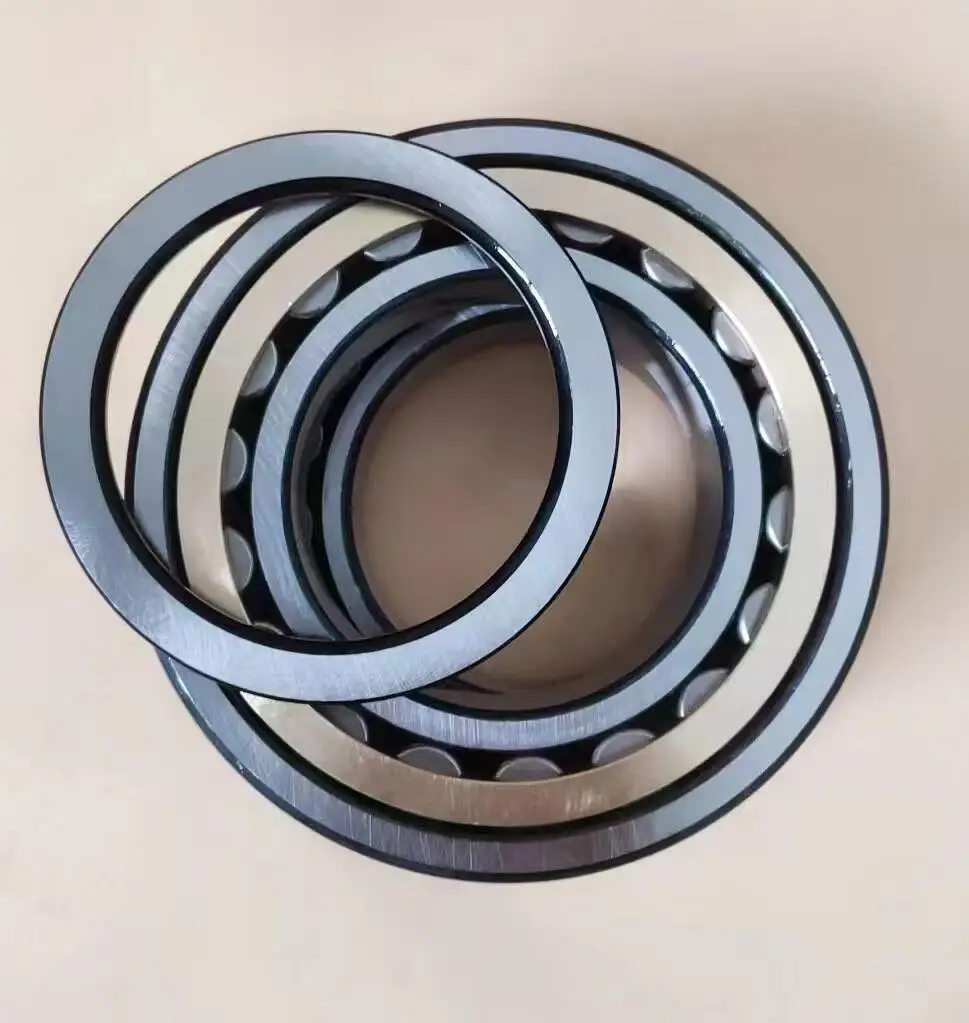

Tapered, Cylindrical, and Spherical Roller Bearings

When the loads become too great for ball bearings, the conversation shifts to roller bearings. The fundamental difference is the nature of the contact between the rolling element and the raceway. A ball makes a "point" contact (which deforms under load into a small ellipse). A roller makes a "line" contact. This line contact distributes the load over a much larger area, granting roller bearings a significantly higher load-carrying capacity. Within the KOYO family, three main types of roller bearings address different challenges.

Tapered Roller Bearings are defined by their conical rollers and raceways. This tapered geometry is their genius. It allows them to accommodate heavy combined loads—both radial and axial—simultaneously. They are the bearing of choice for applications like car and truck wheel hubs, pinion shafts in differentials, and gearbox output shafts, where forces converge from multiple directions. A key feature is that they are separable; the inner ring with its roller and cage assembly (the cone) can be mounted separately from the outer ring (the cup). Typically, they are mounted in pairs, facing each other (face-to-face) or facing away from each other (back-to-back), to handle axial loads in both directions and to allow for the setting of a precise preload.

Cylindrical Roller Bearings are designed for one primary purpose: to carry very heavy radial loads at high speeds. Their rollers are cylinders, providing a long line of contact with the raceways. This makes them ideal for applications like the main shafts of large electric motors, rolling mill stands, and traction motors for railway vehicles. Many designs of KOYO Cylindrical Roller Bearings have ribs on either the inner or outer ring to guide the rollers, but some variations have one ring without ribs, allowing for axial displacement of the shaft relative to the housing. This can be a useful feature for accommodating thermal expansion of a long shaft.

Spherical Roller Bearings are the problem-solvers for applications involving heavy loads and significant shaft misalignment. Imagine a long conveyor belt in a mine. The foundation may settle, or the frame may flex under load, causing the shaft to deflect. A rigid bearing like a Deep Groove Ball Bearing would be quickly destroyed in such a condition. The Spherical Roller Bearing, however, is designed to cope. It has two rows of barrel-shaped rollers and a common, spherically ground raceway in the outer ring. This allows the inner ring, rollers, and cage to pivot freely within the outer ring, accommodating static and dynamic misalignment without inducing internal stresses. This makes them indispensable in heavy, unforgiving applications like mining machinery, paper mills, and large industrial fans.

Specialized Solutions: Needle Roller Bearings, Thrust Bearings, and Bearing Units

Beyond the main categories, KOYO offers a range of specialized products for specific engineering challenges.

Needle Roller Bearings are a variation of cylindrical roller bearings, but their rollers have a very small diameter relative to their length. The result is a bearing with an exceptionally low cross-sectional height. This makes them perfect for applications where radial space is limited, such as in automotive transmissions, universal joints, and two-stroke engines. Despite their slim profile, their multiple line contacts give them a very high radial load capacity.

Thrust Bearings are designed for one job: to support purely axial loads. While other bearings can handle some axial load, thrust bearings are optimized for it. They come in ball and roller varieties. A Thrust Ball Bearing is suitable for light to moderate loads and high speeds, while a Cylindrical or Spherical Roller Thrust Bearing is used for very heavy axial loads, such as those found in crane hooks, screw jacks, and extruder machine spindles.

Bearing Units are a brilliant innovation for simplifying assembly and ensuring reliability. A Bearing Unit combines a bearing (typically a Deep Groove Ball Bearing with a spherical outer ring) with a housing made of cast iron or pressed steel. The most common forms are the "Pillow Block" (which mounts on a flat surface) and the "Flange" unit (which mounts to a machine wall). The key advantage is that the spherical interface between the bearing and the housing allows the unit to accommodate initial static misalignment of the shaft, which is common in fabricated machine frames. These KOYO units, often sold "sealed for life" and pre-lubricated, are a mainstay in agricultural machinery, conveyor systems, and HVAC equipment.

For even more specialized needs, the KOYO catalog includes products like Slewing Ring Bearings, which are large-diameter bearings capable of handling complex, high-moment loads in equipment like cranes and excavators, and Linear Bearings, which facilitate motion along a straight path rather than rotation.

Understanding KOYO's Naming and Numbering System

The string of letters and numbers on a bearing is not a random code; it is a dense summary of its identity. Understanding this nomenclature is a powerful skill. A typical KOYO designation might look like 6205-2RSC3.

- 62: The first digit(s) identify the bearing type. '6' signifies a single-row Deep Groove Ball Bearing. '2' would be a Spherical Roller Bearing, '7' an Angular Contact Ball Bearing, 'NU' a Cylindrical Roller Bearing.

- 05: The last two digits of the basic number represent the bore size. For sizes 04 and up, multiplying by 5 gives the bore diameter in millimeters. So, '05' means a 25mm bore (5 x 5). Sizes 00, 01, 02, and 03 correspond to 10mm, 12mm, 15mm, and 17mm respectively.

- -2RS: This is a suffix indicating the sealing arrangement. '2RS' means a contact seal on both sides. 'ZZ' would mean metal shields on both sides. An open bearing would have no suffix here.

- C3: This suffix indicates the internal radial clearance. 'C3' means the bearing has a greater-than-normal internal clearance. This is often required for applications with a tight press fit or a high operating temperature. Normal clearance has no suffix.

Learning to read this code allows you to understand a bearing's core attributes at a glance, making you a far more efficient and effective selector of the correct component from the extensive list of KOYO products available.

Step 3: Scrutinizing Material and Quality Specifications

Once the appropriate bearing type and size have been identified, the inquiry must deepen, moving from the macro-level geometry to the micro-level substance of the component itself. Two KOYO bearings may share the same part number, the same dimensions, and the same external appearance, yet possess profoundly different capabilities due to variations in their material composition, manufacturing precision, and internal design. These are not trivial details. They are the very factors that determine a bearing's ultimate performance, its resistance to failure, and its service life. To overlook them is to assume that all steel is the same, that all manufacturing processes are equal—an assumption that can lead to costly and dangerous misapplications.

This scrutiny is particularly salient for industries operating under severe conditions. In the mining sector of South Africa or the oil and gas fields of the Middle East, abrasive wear and high stresses are constants. In the high-speed machinery of Russian manufacturing plants or the precision electronics assembly in Southeast Asia, dimensional accuracy is paramount. Understanding the material and quality specifications of a KOYO bearing is what allows an engineer to match the component not just to the application's dimensions, but to its true operational intensity.

The Heart of the Matter: Steel Composition and Heat Treatment

The soul of a rolling bearing resides in its steel. The vast majority of KOYO bearings are manufactured from a high-carbon chromium bearing steel, typically corresponding to international standards like SAE 52100 in the USA, EN 100Cr6 in Europe, or SUJ2 in Japan. This material is chosen for a very specific combination of properties. Its high carbon content allows it to be hardened to a very high degree, providing exceptional resistance to the compressive stresses and surface fatigue that define a bearing's life. The chromium content enhances its hardenability, ensuring that even in larger cross-sections, a consistent hardness can be achieved.

However, the raw material is only half the story. The heat treatment process is what unlocks the steel's potential. For most standard KOYO bearings, this involves through-hardening. The entire component—inner ring, outer ring, and rolling elements—is heated to a high temperature (a process called austenitizing) and then rapidly cooled (quenched). This transforms the steel's microstructure into martensite, a very hard and wear-resistant phase. Following the quench, a tempering process is applied—a lower-temperature heating cycle that relieves internal stresses and imparts a crucial degree of toughness, preventing the bearing from being overly brittle. The result is a component with high hardness throughout its entire volume, providing excellent durability under rolling contact fatigue.

For certain heavy-duty applications, particularly those involving severe shock loads, KOYO may employ case-hardening. In this process, a low-carbon steel is used, and its surface is infused with carbon (carburizing). When heat-treated, only the high-carbon "case" becomes hard, while the low-carbon "core" remains softer and tougher. This creates a bearing with a wear-resistant surface and a highly ductile, impact-resistant core, making it ideal for applications like rolling mills or construction equipment where extreme shocks are common.

Precision and Tolerance Classes

A bearing is a precision instrument. The degree of that precision is defined by its tolerance class. These classes, standardized by organizations like ISO (International Organization for Standardization) and JIS (Japanese Industrial Standards), dictate the permissible deviations in a bearing's critical dimensions, such as its bore diameter, outer diameter, width, and running accuracy (runout).

The standard tolerance class for most bearings is designated as P0 (or sometimes PN). For the vast majority of general industrial and automotive applications, from electric motors to conveyor rollers, KOYO bearings of P0 class provide excellent performance and value.

However, certain applications demand greater precision. As rotational speeds increase or as the need for positioning accuracy becomes more acute, deviations in a bearing's geometry can lead to vibration, noise, and inaccuracies in the machine's operation. For these situations, higher precision classes are specified:

- P6: Offers tighter tolerances than P0. Often used in applications where noise and vibration levels need to be controlled, or in moderately high-speed machinery.

- P5: A common choice for precision applications, such as the main spindles of machine tools (lathes, milling machines), where both rotational accuracy and speed capability are important.

- P4: A very high precision class used for ultra-high-speed machine tool spindles, measuring instruments, and other applications demanding the utmost running accuracy.

It is a common misconception to believe that a higher precision class is always "better." Selecting a P4 bearing for a simple conveyor roller is not only economically wasteful but can also be technically inappropriate. The tight tolerances of a high-precision bearing demand equally precise machining of the shaft and housing, as well as extremely clean and careful mounting procedures. Using a high-precision KOYO bearing in a low-precision environment negates its benefits and can even lead to problems like improper load distribution or reduced clearance. The choice of tolerance class must be a deliberate one, guided by the genuine requirements of the application for speed and running accuracy.

The Unseen Protector: Cage Materials and Their Properties

The cage (or retainer) is the unsung hero of the bearing. Its primary functions are to separate the rolling elements to prevent them from rubbing against each other, to maintain their proper spacing, and to guide them through the load zone. While it is not a primary load-bearing component, the cage's material and design can have a profound impact on a bearing's performance, particularly its speed capability, temperature resistance, and robustness.

The most common cage type, especially in smaller to medium-sized KOYO Ball Bearings, is the pressed steel cage. These are lightweight, strong, and economical to produce. They are typically made from a ribbon of low-carbon steel that is stamped and riveted or crimped together. They perform admirably in a huge range of general-purpose applications.

For more demanding conditions, other materials are employed. In larger bearings or those subjected to high speeds and vibration, a machined brass cage is often preferred. These are manufactured from a solid tube or casting of brass, resulting in a one-piece, highly robust component. Brass has good inherent lubricity and is less reactive with the ammonia compounds that can form in some lubricants under high temperatures. Their high strength makes them resistant to the stresses induced by high-speed rotation and vibration.

In the realm of very high-speed applications, polyamide (nylon) cages have become increasingly popular. These polymer cages, often glass-fiber reinforced, are lightweight, which reduces centrifugal forces at high RPMs. They have excellent sliding properties against steel and can tolerate a certain degree of misalignment. Their flexibility allows for cage designs that can hold more rolling elements, sometimes increasing the bearing's load capacity. However, their primary limitation is temperature. Standard polyamide cages are typically limited to continuous operation below 120°C. They are also sensitive to certain synthetic oils and aggressive chemical environments.

The selection of the cage material is another layer of tailoring the KOYO bearing to its specific task. A high-vibration shaker screen in a quarry might benefit from the robustness of a machined brass cage, while a high-speed router spindle would leverage the lightweight, low-friction properties of a polyamide cage.

Step 4: Mastering Lubrication and Sealing Strategies

Having selected a KOYO bearing with the appropriate geometry, materials, and precision, the focus must now shift to its preservation. A bearing, no matter how perfectly manufactured, cannot survive without a crucial element: lubrication. Lubrication is the lifeblood of a bearing. Its primary role is to create a microscopic film that separates the moving surfaces—the rolling elements from the raceways. Without this film, direct metal-to-metal contact would occur, leading to rapid wear, high friction, excessive heat, and catastrophic failure in a remarkably short time.

Furthermore, the bearing must be protected from the external world. The same lubricant that protects the bearing from itself must be protected from contamination. This dual challenge—effective lubrication and robust sealing—is a continuous process, not a one-time decision. It is a strategy that must be thoughtfully designed and diligently executed, especially in the challenging environments prevalent in many South American, Middle Eastern, and Southeast Asian industries, where dust, moisture, and process fluids are a constant threat.

Grease vs. Oil: Making the Right Lubricant Choice

The first fundamental decision is the type of lubricant: grease or oil.

Grease is the lubricant of choice for the vast majority of rolling bearing applications. A grease is essentially a base oil (mineral or synthetic) that is held in a sponge-like matrix of a thickening agent (like a lithium, calcium, or polyurea soap). This structure gives grease its semi-solid consistency, which is its key advantage. It is easy to retain within the bearing housing, provides a degree of sealing against contaminants, and requires less complex housing designs.

When choosing a grease for a KOYO bearing, several properties are paramount. The base oil viscosity is the most significant. It must be appropriate for the bearing's size and speed. A slow, heavily loaded bearing requires a high-viscosity oil to create a robust film, while a high-speed bearing needs a lower-viscosity oil to minimize fluid friction (churning) and heat generation. The consistency, defined by the NLGI (National Lubricating Grease Institute) grade, determines how stiff the grease is. An NLGI 2 grade is a common multipurpose choice. The thickener type influences the grease's water resistance, thermal stability, and mechanical stability. A lithium-complex grease offers good all-around performance, while a polyurea grease might be chosen for long-life, sealed-for-life applications due to its excellent thermal and oxidative stability.

Oil, as a lubricant, is generally used when speeds or temperatures are too high for grease to be effective. At very high speeds, the churning of grease can generate excessive heat. A circulating oil system can not only lubricate but also actively carry heat away from the bearing. Oil is also preferred in applications like gearboxes where it is already being used to lubricate gears, allowing for a single, shared lubrication system. The primary property of a lubricating oil is its viscosity, typically defined by an ISO VG (Viscosity Grade). As with grease, the selection is a balance: high enough to provide an adequate film, but low enough to minimize drag and heat.

The decision between grease and oil is a function of the application's DN value (a product of bore diameter and RPM), the operating temperature, and the existing machine design.

The Role of Seals and Shields in Contaminant Exclusion

Sealing is the bearing's first line of defense. KOYO offers bearings with integral sealing solutions that are remarkably effective for their size. The choice between them depends entirely on the severity of the external environment.

Shields (designated by KOYO with suffixes like Z or ZZ) are non-contact closures. They consist of a pressed steel disc fitted into the outer ring, which extends inwards to form a very narrow gap with the inner ring. Because there is no contact, shields add virtually no friction and do not have a speed limit. They are effective at retaining grease and excluding larger, solid contaminants like dirt or wood chips. However, they offer little protection against fine dust, moisture, or fluids, as these can still be drawn through the small gap by pressure differentials or capillary action. A shielded bearing is suitable for relatively clean environments, like inside an electric motor casing.

Seals (designated with suffixes like RS or 2RS) provide a much higher degree of protection. These are typically made from a synthetic rubber (like nitrile or Viton) that is bonded to a steel insert for rigidity. The seal is fitted to the outer ring, and its flexible "lip" rides in constant contact with a ground surface on the inner ring. This physical contact creates a formidable barrier against fine dust, water spray, and other contaminants. They are the standard choice for any application exposed to the elements or to process contamination, such as in agricultural equipment, car wheels, or food processing machinery. The trade-off for this superior protection is a small amount of friction and heat generated by the rubbing seal lip, which can impose a limiting speed on the bearing that is lower than that of an equivalent open or shielded bearing.

For extremely contaminated environments, such as in mining or cement production, even integral seals may be supplemented by external sealing arrangements like labyrinth seals or taconite seals in the housing design.

Calculating Relubrication Intervals for Optimal Life

For bearings that are not "sealed for life," relubrication is a maintenance task. The question is not if but when. Relubricating too frequently can be as harmful as not lubricating enough. Over-greasing a bearing can cause the rolling elements to churn the excess grease, leading to a rapid temperature rise and potential failure.

The calculation of the correct relubrication interval is a complex topic, but a simplified approach can provide a reliable starting point. Bearing manufacturers like JTEKT provide diagrams and formulas that estimate the basic relubrication interval (t_f) based on the bearing type, bore size, and rotational speed. This base interval assumes ideal operating conditions: a moderate load, a clean environment, and an operating temperature below 70°C.

The crucial step is to then apply correction factors to this base interval to account for the realities of the application:

- Temperature: For every 15°C increase in operating temperature above 70°C, the relubrication interval should be halved.

- Contamination: In dirty environments, the interval may need to be drastically shortened. Correction factors can range from 0.7 for slight contamination down to 0.1 for severe contamination.

- Moisture: The presence of water requires more frequent grease replenishment to purge moisture and prevent corrosion.

- Vibration: High vibration can cause grease to break down or be expelled from the bearing, necessitating shorter intervals.

- Orientation: A bearing on a vertical shaft may need more frequent relubrication than one on a horizontal shaft, as gravity can cause the grease to slump downwards and away from the rolling elements.

By systematically applying these factors, one can move from a generic recommendation to a tailored maintenance schedule that ensures the KOYO bearing is always protected by a healthy charge of effective lubricant, maximizing its potential service life. A diligent approach to lubrication and sealing is the most cost-effective form of reliability insurance available.

Step 5: Calculating and Predicting Bearing Service Life

The selection of a bearing is an investment in future performance. A natural and pressing question arises from this investment: how long will it last? Predicting the service life of a bearing is not an act of prophecy, but a statistical calculation grounded in the principles of material science and mechanics. It allows an engineer to design a machine with a known reliability target, and it enables a maintenance manager to plan for replacements, manage inventory, and avoid the immense costs associated with unexpected downtime. The ability to perform and interpret these life calculations is a hallmark of a technically proficient bearing user.

This process transforms the bearing from a simple commodity into a predictable and manageable asset. For capital-intensive industries in Russia's manufacturing sector or South Africa's mining operations, the ability to forecast component life is central to budgeting and operational planning. It is the bridge between engineering design and financial reality.

The Foundation: L10 Life Calculation (ISO 281)

The cornerstone of modern bearing life prediction is the L10 life calculation, standardized in ISO 281. The "10" in L10 refers to a reliability of 90%. That is, the L10 life is the number of revolutions (or operating hours at a constant speed) that 90% of a group of apparently identical bearings can be expected to complete or exceed before the first evidence of material fatigue (spalling) develops. It is a statistical measure; it does not mean every bearing will fail at precisely this point. 10% may fail earlier, while 90% will last longer, often much longer.

The calculation itself is elegantly simple in its basic form:

L10 = (C / P)^p

Where:

- L10 is the basic rating life in millions of revolutions.

- C is the Basic Dynamic Load Rating. This is a value listed in the KOYO bearing catalog for every bearing. It represents the constant load under which a bearing would achieve a basic rating life of one million revolutions. It is a measure of the bearing's fatigue resistance.

- P is the Equivalent Dynamic Bearing Load. This is the calculated load that represents the combined effect of all the radial and axial forces acting on the bearing. If the load is purely radial, P is simply the radial load. If there is a combination of radial (Fr) and axial (Fa) loads, P is calculated using the formula P = XFr + YFa. The factors X and Y are also found in the bearing catalog and depend on the bearing type and the ratio of axial to radial load.

- p is the life exponent. For all ball bearings, p = 3. For all roller bearings (cylindrical, tapered, spherical), p = 10/3 (approximately 3.33). The higher exponent for roller bearings reflects their higher load-carrying capacity and different contact mechanics.

To convert the L10 life from millions of revolutions to operating hours, the following formula is used:

L10h = (1,000,000 * L10) / (60 * n)

Where n is the rotational speed in RPM.

This L10 calculation provides a solid baseline for comparing the suitability of different KOYO bearings under a given load condition.

Beyond L10: The Adjusted Rating Life

The basic L10 calculation makes a significant assumption: that the bearing is operating under ideal conditions. It primarily considers the load and the bearing's intrinsic fatigue strength. However, as we have established, real-world conditions are rarely ideal. Lubrication quality, contamination levels, and internal stresses all have a profound impact on a bearing's true service life.

To account for these factors, modern bearing science uses the concept of the Adjusted Rating Life. This method modifies the basic L10 life by a factor, often called the life modification factor (designated as aiso by JTEKT or aSKF by other manufacturers), which synthesizes the effects of the lubrication regime and the fatigue load limit of the steel.

Lna = a1 * a_iso * L10

Where:

- L_na is the adjusted rating life with a certain reliability (n).

- a1 is the life adjustment factor for reliability (a1 = 1 for 90% reliability).

- a_iso is the life modification factor that considers lubrication, contamination, and the fatigue limit.

Calculating aiso is more complex. It involves determining the viscosity ratio (kappa, κ), which is the ratio of the actual lubricant viscosity at operating temperature to the minimum required viscosity for adequate lubrication. It also considers a contamination factor (ηc) and the ratio of the fatigue load limit (Pu) to the equivalent load (P).

The key insight from this advanced method is that if the lubrication is good (high kappa value) and the load is low relative to the bearing's fatigue limit, the life modification factor can be significantly greater than 1, predicting a service life many times longer than the basic L10. Conversely, if lubrication is poor (low kappa, due to low viscosity or high temperature) or if contamination is present (low η_c), the factor can be much less than 1, drastically reducing the expected life. This method underscores the immense value of good lubrication and cleanliness, showing mathematically how they can extend bearing life from thousands of hours to, in some cases, a theoretically infinite life. Advanced tools for these calculations are often provided by leading manufacturers like the ones behind a comprehensive bearing product portal.

Common Modes of Bearing Failure and Their Root Causes

When a bearing does fail, it often leaves behind clues to the cause of its demise. Being able to read these clues is a vital skill for preventing future failures. It turns a costly failure into a valuable lesson. Here are some common failure modes:

- Classic Fatigue (Spalling): This is the "natural" end of a bearing's life. It appears as a flaking or spalling of material from the raceway or rolling elements. If it occurs after the calculated L10 life has been reached, it is not a sign of a problem. If it occurs prematurely, it points to overloading or an under-specified bearing.

- Abrasive Wear: This appears as a dull, lapped, or matte finish on the raceways and rolling elements. It is caused by fine, hard contaminants in the lubricant that grind away the surfaces. The solution is improved sealing and cleaner lubrication practices.

- Corrosion: Red or brown rust patches on the surfaces indicate the presence of water or corrosive agents. This can be caused by moisture ingress or by condensation within the housing. Better sealing or using a grease with enhanced corrosion inhibitors is necessary.

- False Brinelling: This appears as linear, polished depressions in the raceway, oriented axially. It is not caused by rotation but by small-amplitude vibration or oscillation while the bearing is stationary. The micro-movements wear away the lubricant film, leading to fretting corrosion. It is common in machinery that is transported long distances or in standby equipment subjected to ambient vibration.

- Electrical Fluting: This appears as a distinctive washboard or "fluting" pattern across the raceway. It is caused by the passage of electric current through the bearing, which creates tiny arcs that melt and pit the steel. It is a common problem in modern variable-frequency drive (VFD) controlled motors. The solution involves insulating the bearing or providing an alternative path for the current.

| Failure Mode | Visual Appearance | Potential Causes |

|---|---|---|

| Normal Fatigue | Spalling/flaking of surface metal. | End of calculated service life. |

| Premature Fatigue | Spalling/flaking before expected life. | Overloading, tight fit reducing clearance. |

| Abrasive Wear | Dull, matte, or lapped surfaces. | Contaminated lubricant (dust, dirt, sand). |

| Corrosion | Red/brown rust spots or areas. | Water or corrosive fluid ingress, condensation. |

| Brinelling (True) | Indentations matching rolling element spacing. | Severe impact load or static overload. |

| False Brinelling | Axial lines/grooves in the raceway. | Vibration while the bearing is stationary. |

| Electrical Fluting | Grayish, washboard-like pattern. | Passage of electrical current through the bearing. |

| Smearing/Scuffing | Discolored, "smeared" surface texture. | Inadequate lubrication, excessive speed/acceleration. |

By carefully examining a failed KOYO bearing and comparing its appearance to this diagnostic guide, a technician can pinpoint the root cause of the problem and implement effective corrective actions, breaking the cycle of repeated failures.

Step 6: Ensuring Proper Installation and Maintenance Practices

The journey towards bearing reliability does not end with selection and procurement. A perfectly specified, authentic KOYO bearing can be doomed to a short and brutal life if it is installed incorrectly or maintained improperly. The moments of installation are perhaps the most perilous in a bearing's entire lifecycle. It is during this process that microscopic damages can be introduced, damages that will grow into macroscopic failures under the stresses of operation. Similarly, the ongoing practices of condition monitoring and maintenance determine whether a bearing will reach its full potential life or succumb prematurely to a preventable issue.

This practical, hands-on stage of the process requires discipline, the right tools, and a respect for the precision nature of the component. For maintenance teams in diverse locations—from a bustling factory in Southeast Asia to a remote pumping station in South America—adherence to proper procedures is the ultimate guarantor of machine availability. It is where theoretical knowledge is translated into tangible reliability.

The Importance of Correct Mounting Techniques

Mounting a bearing involves fitting it onto a shaft and into a housing. The fits are precise; typically, the rotating ring has a tight "interference" fit, while the stationary ring has a looser "clearance" fit. Applying the bearing with the correct technique is paramount.

The single greatest sin in bearing installation is the use of brute force, particularly striking the bearing directly with a hammer or a hardened drift. The impact forces from a hammer blow are immense and uncontrolled. They can easily exceed the static load capacity of the steel, creating tiny dents in the raceways known as brinelling. Each of these dents is a stress concentration point that will drastically shorten the bearing's fatigue life. Furthermore, if force is transmitted from one ring to the other through the rolling elements during mounting (e.g., pressing on the outer ring to mount the bearing onto a shaft), the concentrated forces can cause similar damage. The cardinal rule of mounting is to apply force only to the ring that is being fitted.

For small to medium-sized bearings, cold mounting is common. This should be done using a proper bearing fitting tool kit, which includes sleeves and impact rings designed to apply a steady, even pressure to the correct ring face. A hydraulic press is ideal.

For larger bearings, the interference fit can be so tight that the force required for cold mounting becomes excessive. In these cases, hot mounting is the preferred method. The principle is simple: heating the bearing causes it to expand, temporarily increasing its bore diameter. This allows it to be slid onto the shaft easily, without force. As it cools, it shrinks to create the required tight fit. The key to safe hot mounting is the heating method. The use of an open flame or an oil bath is strongly discouraged. An open flame can overheat the bearing locally, altering its metallurgical properties, while hot oil baths present safety hazards and contamination risks. The professional and correct tool is an induction heater. These devices use a magnetic field to induce eddy currents within the bearing, heating it rapidly, evenly, and to a precisely controlled temperature. A temperature of 110°C is typically sufficient for most applications and is well below the point where the steel's properties would be affected.

Setting Internal Clearance and Preload

Before a bearing is mounted, it has a certain amount of "play" or looseness. This is the radial internal clearance (RIC). It is the total distance one ring can be moved relative to the other in the radial direction. This clearance is a critical design parameter and is specified by suffixes like C3 or C4 on the KOYO bearing.

It is a common misunderstanding that this clearance is a measure of quality; it is not. It is a functional requirement. When a bearing is mounted with an interference fit on the shaft and/or in the housing, the inner ring expands and the outer ring is compressed, which reduces the internal clearance. Furthermore, during operation, the inner ring typically runs hotter than the outer ring, causing it to expand more. This further reduces the clearance. The initial "cold" clearance must be large enough to ensure that a small, positive "operational" clearance remains once the bearing is mounted and at its running temperature. A bearing running with insufficient or negative clearance (a state of preload) will generate excessive heat and fail very quickly.

This is why C3 clearance (greater than normal) is so commonly specified for applications like electric motors, where the shaft fits are tight and the inner ring runs warm. For applications with even higher temperatures or tighter fits, C4 or C5 clearances might be necessary.

In some specific applications, a negative clearance, or preload, is desirable. This is particularly true for bearing arrangements that require high stiffness and precise rotational control, such as machine tool spindles or automotive pinions. In these cases, pairs of Angular Contact Ball Bearings or Tapered Roller Bearings are mounted in opposition to each other and an axial load is deliberately applied to them. This removes all internal clearance, seating the rolling elements firmly in the raceways. Preloading increases rigidity and running accuracy, but it must be set very precisely. Too little preload and the benefits are lost; too much preload and the bearing will overheat and fail.

Condition Monitoring: The Key to Predictive Maintenance

The most advanced maintenance strategies move beyond reactive (fix it when it breaks) or preventive (fix it on a schedule) approaches to a predictive model. Predictive Maintenance (PdM) involves using technology to monitor the real-time condition of machinery to detect the very earliest signs of a developing fault. This allows maintenance to be scheduled precisely when it is needed, avoiding both unexpected failures and unnecessary scheduled replacements of healthy components.

For bearings, the most powerful PdM technology is vibration analysis. As a bearing begins to develop microscopic defects like a tiny spall on a raceway, each rolling element that passes over the defect generates a tiny, high-frequency impact. These impacts, while imperceptible to the human ear or hand, can be detected by a sensitive accelerometer connected to a data collector. Sophisticated software can then analyze the frequency spectrum of the vibration signal. Because the frequencies generated by a bearing defect are directly related to the bearing's geometry and rotational speed, the software can identify not only that a bearing is failing, but often whether the defect is on the inner ring, outer ring, a rolling element, or the cage. This allows for very early and precise fault detection, often months before the bearing would otherwise fail.

Other technologies supplement this. Thermal imaging with an infrared camera can be used to monitor bearing temperatures, with a rising trend indicating a potential problem with lubrication or clearance. Acoustic emission uses high-frequency sensors to "listen" for the stress waves generated by microscopic cracking or lubricant film breakdown. Oil analysis can be used for large, oil-lubricated systems to detect the presence of wear particles or lubricant degradation.

By embracing these condition monitoring techniques, an organization can transform its maintenance department from a cost center focused on reacting to failures into a reliability team that proactively ensures the health of its critical machinery, maximizing the service life of every KOYO bearing it installs.

Step 7: Authenticating Your KOYO Bearings and Choosing a Reliable Supplier

After navigating the complex technical landscape of bearing selection, lubrication, and installation, a final, critically important step remains. This step addresses a non-technical but pervasive threat: the risk of counterfeit products. The global market, particularly in rapidly growing economies, is unfortunately rife with counterfeit bearings. These are products manufactured to look identical to genuine articles from reputable brands like KOYO, but they are made with inferior materials, to poor tolerances, and without the rigorous quality control that defines an authentic product. Using a counterfeit bearing is not a cost-saving measure; it is an invitation for disaster.

The consequences of a counterfeit bearing failure range from costly to catastrophic. At best, the bearing will fail prematurely, leading to unscheduled downtime and replacement costs that far exceed any initial savings. At worst, its failure can cause extensive secondary damage to shafts, housings, and entire machines, or even lead to a dangerous safety incident. Therefore, the final acts of due diligence—authenticating the product and verifying the supplier—are paramount to protecting your investment and your operations.

The Pervasive Threat of Counterfeit Bearings

Counterfeiters have become increasingly sophisticated. They can expertly mimic the packaging, markings, and overall appearance of genuine KOYO bearings. An unsuspecting buyer, looking at a counterfeit product, may see no outward signs of a problem. The difference, however, is profound and lies hidden within.

A counterfeit bearing may be made from low-quality steel that lacks the purity, hardness, and fatigue resistance of genuine bearing steel. Its internal geometry may be incorrect, and its manufacturing tolerances may be wide and uncontrolled. The heat treatment might be improper or non-existent, resulting in a soft component that will wear or deform quickly under load. The rolling elements may be of inconsistent size, leading to poor load distribution. The seals may be made from low-grade rubber that will quickly crack or fail.

For a procurement manager in South America or a maintenance engineer in the Middle East, the allure of a significantly lower price can be strong. However, it is essential to understand that this price difference reflects a cavernous gap in quality. A genuine KOYO bearing is the result of over a century of materials science research, precision manufacturing investment, and quality control systems developed by JTEKT. A counterfeit is a hollow imitation that leverages the brand's reputation without delivering any of its substance.

Identifying Genuine KOYO Products: Packaging and Markings

While counterfeiters are good, there are often subtle signs that can betray a fake product. Vigilance is key.

Packaging: Examine the box carefully. Genuine KOYO packaging is of high quality, with clear, crisp printing and consistent branding. Look for logos that are blurry, discolored, or have incorrect proportions. Check for spelling errors or awkward phrasing in the text. KOYO uses specific carton designs and color schemes that are consistent across product lines. Any deviation is a red flag.

Markings on the Bearing: Every KOYO bearing is marked with its part number and the KOYO brand name. On modern bearings, this is typically done with a high-quality laser etching. The marking should be sharp, clear, and permanent. On a counterfeit, the marking might be a crude stamping, a faint or blurry etching, or may even be acid-etched. Compare the font and style of the marking to a known genuine product.

Overall Quality and Finish: A genuine KOYO bearing has a smooth, finely ground finish on its raceways and faces. The edges are typically well-chamfered. A counterfeit may have a rougher surface finish, sharp edges, or visible machining marks. The "feel" of the bearing when rotated by hand can also be an indicator; a genuine bearing should feel smooth and consistent, while a fake may feel rough, notchy, or loose.

Authentication Apps: Recognizing the severity of the counterfeit problem, JTEKT, like many other major bearing manufacturers, has developed tools to help customers. They have introduced QR codes on their packaging that can be scanned with a smartphone app. This app connects to a JTEKT database to verify the authenticity of the product's unique serial number. Always use the official KOYO or JTEKT authentication app for this purpose.

Vetting Your Supplier: The Final Link in the Chain

The single most effective way to guarantee you are receiving genuine KOYO bearings is to purchase them only from authorized KOYO distributors.

An authorized distributor has a direct contractual relationship with JTEKT. They receive their stock directly from the manufacturer's supply chain, ensuring a 100% genuine product. They have access to the manufacturer's technical support, engineering resources, and warranty processes. They are trained in proper storage and handling procedures to ensure the bearings you receive are in perfect condition.

How can you identify and vet a supplier?

- Ask for Proof of Authorization: A legitimate authorized distributor will have no hesitation in providing you with documentation of their status. You can often verify this on the official KOYO or JTEKT corporate website, which may have a distributor locator tool.

- Be Wary of "Too Good to Be True" Pricing: If a supplier is offering KOYO bearings at a price that is dramatically lower than the general market rate, it is a massive red flag. The price of a genuine, high-quality industrial component is relatively stable. Huge discounts often indicate a questionable source.

- Examine the Supplier's Business: A professional supplier will have a proper warehouse, a knowledgeable sales and technical staff, and a history in the industry. A supplier operating out of a small, disorganized shop or solely through an anonymous online marketplace warrants extreme caution. A well-structured "about us" page, like the one found on a site like skf-eu.com/about-us/, can offer insights into a company's professionalism and history.

- Demand Traceability: A reputable supplier should be able to provide traceability for their products, linking them back through the supply chain to the manufacturer.

In the end, your choice of supplier is as important as your choice of bearing. A trustworthy supplier is not just a vendor; they are a partner in your company's reliability. By insisting on purchasing authentic KOYO bearings through authorized channels, you are making the final and most important investment in ensuring that all the careful work of selection, lubrication, and installation pays off in the form of long, reliable machine life.

Frequently Asked Questions (FAQ)

What is the primary difference between a KOYO Ball Bearing and a Roller Bearing? The fundamental difference lies in the shape of the rolling element and how it contacts the raceway. A Ball Bearing uses spherical balls, which make a small "point" contact. This allows for very high rotational speeds but offers a moderate load capacity. A Roller Bearing uses various forms of rollers (cylindrical, tapered, etc.), which make a "line" contact. This larger contact area allows them to support much heavier loads, but they generally have lower speed limits than ball bearings.

How can I tell if my KOYO bearings are fake? The most reliable method is to purchase only from authorized KOYO distributors. However, you can look for signs like poor quality packaging with blurry logos or spelling errors, crude or inconsistent markings on the bearing itself, and a rough surface finish. Many modern KOYO product boxes feature a QR code that can be scanned with JTEKT's official app to verify authenticity. If a price seems too good to be true, it likely is.

What does the 'C3' marking on a KOYO bearing mean? The 'C3' suffix denotes the bearing's Radial Internal Clearance (RIC). 'C3' signifies that the bearing is manufactured with an internal clearance that is greater than the "Normal" or standard clearance. This extra room is often necessary to compensate for the reduction in clearance that occurs from tight press fits on the shaft and/or in the housing, and from thermal expansion when the bearing reaches its operating temperature. It is a functional specification, not a sign of quality.

Can I use a KOYO automotive bearing in an industrial machine? It is generally not recommended unless the specific bearing is rated for both applications. Automotive bearings are designed for the specific load, speed, and life cycle requirements of a vehicle, which can be very different from the continuous, heavy-duty operation of many industrial machines. An industrial KOYO bearing is typically designed for longer service life under more consistent operating conditions. Always select a bearing based on the requirements of the specific industrial application.

How often should I lubricate my KOYO bearings? This depends heavily on the operating conditions. For bearings that are not sealed-for-life, the relubrication interval is calculated based on bearing type, size, and speed, and then adjusted for factors like temperature, contamination, vibration, and orientation. As a general rule, for every 15°C increase in temperature above 70°C, the interval should be halved. In very dirty or wet environments, intervals must be shortened significantly to purge contaminants. Following the manufacturer's calculation guidelines is the best practice.

What are KOYO Bearing Units and why are they useful? KOYO Bearing Units, such as pillow blocks and flanged units, are integrated assemblies that consist of a bearing (typically a sealed deep groove ball bearing) pre-mounted in a cast iron or pressed steel housing. Their primary advantage is ease of installation and their ability to accommodate initial static misalignment of the shaft. This self-aligning feature is very useful in fabricated machine frames, such as on conveyors or agricultural equipment, where perfect alignment is difficult to achieve.

Are KOYO bearings made only in Japan? While KOYO was founded in Japan and JTEKT Corporation maintains a significant manufacturing and research presence there, it is a global company. JTEKT operates numerous manufacturing plants for KOYO bearings around the world, including in Europe, North America, and other parts of Asia. All facilities operate under the same strict Japanese quality control standards to ensure consistent product quality regardless of the manufacturing location.

Conclusion

The selection and application of a KOYO bearing, when approached with intellectual rigor and practical discipline, transcends a simple component purchase. It becomes a deliberate act of engineering that underpins the very reliability and economic viability of a machine. This guide has sought to illuminate a path, a seven-step methodology that begins with an empathetic understanding of the application's unique world—its forces, its speeds, its environmental adversaries. It progresses through a rational navigation of the vast KOYO portfolio, a deep dive into the substance of material and precision, and a strategic mastery of lubrication and sealing.

By learning to calculate and predict service life, the bearing is transformed from an unknown variable into a manageable asset. By adhering to meticulous installation and maintenance protocols, its potential is preserved. And by exercising vigilance in authentication and supplier selection, the entire endeavor is safeguarded from the pervasive threat of counterfeits. This structured process empowers engineers and technicians in the demanding markets of South America, Russia, Southeast Asia, and beyond. It equips them with the knowledge to move beyond mere replacement and toward true reliability engineering, ensuring that every rotating shaft is supported not just by steel and grease, but by a foundation of sound judgment and technical excellence.

References

JTEKT Corporation. (2020). Ball & roller bearings catalog (CAT. No. B2001E). JTEKT Corporation. Retrieved from

ISO. (2018). ISO 281:2007 Rolling bearings — Dynamic load ratings and rating life. International Organization for Standardization. Retrieved from

Stolarski, T. A., & Tobe, S. (2011). Rolling bearings in service: analysis and practice. Professional Engineering Publishing.

NTN Corporation. (n.d.). Bearing technical data. NTN Corporation. Retrieved from

Harris, T. A., & Kotzalas, M. N. (2006). Advanced concepts of bearing technology: Rolling bearing analysis (5th ed.). CRC Press. https://doi.org/10.1201/9781420006622

SKF. (n.d.). About SKF. SKF Group. Retrieved from

SKF. (n.d.). Products. SKF Group. Retrieved from

Zaretsky, E. V. (Ed.). (1997). STLE life factors for rolling bearings (SP-34). Society of Tribologists and Lubrication Engineers.

Matsuyama, T., & Tsuchiya, A. (2015). Recent bearing technologies for industrial machinery. JTEKT Engineering Journal, 1011E, 2-8. Retrieved from

World Bearing Association. (n.d.). Stop fake bearings. WBA. Retrieved from